What you need to know about a hydraulic arrow for heating: why is it so important?

Hydraulic separator - a device used to join parts together bindings into a single, automatically regulating machine.

It is intended to separate contours.

Hydraulic arrow: what is it

The device is designed to separate contours. First necessarily contains a boiler, sometimes a circulation pump. Others contain other devices: radiators, expansion tanks, heated floors.

Appearance and purpose

The unit looks like a large electrical plug with branches. Most devices have only two projections: for communication with the heater.

A limited number of pipes emerge from the side parts, parallel connected to each other.

The upper ones are for hot water, and the lower ones are for cold water.

Design

Depends on the manufacturer and the task for which it is installed. A quality tank has at least 6 branches. Two of the last six serve technical purposes: air release and sludge removal. They are directed upwards and downwards, respectively.

A hydraulic arrow is a tank with containers inside, connected by valves. First serves to contain hot water, second - cold. If there is not enough liquid in one of the circuits, a hole opens and mixing occurs.

Why is it needed in the heating system?

The device automatically separates the coolant flows along several contours. The working fluid, entering the device, passes through pipes. Coming from the boiler, the water is transferred through the pipes to the desired location.

Return collects in the tank, then returns to the heater. If necessary, part of the heated substance is combined with the cold one for the return journey. The opposite option is possible, in which the cooled liquid again goes through the piping.

The purpose of the device is combine several circuits into a single mechanism. This is required when there are multiple circulation pumps distributed throughout the piping. The device is also useful for creating a system with several boilers: It will help to divide the work between the heaters, allowing some to rest.

Drawing

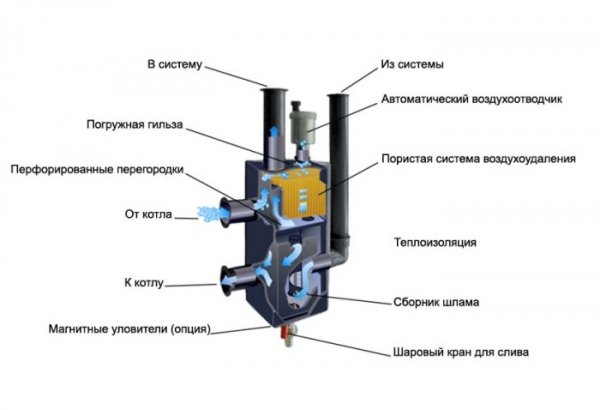

The general appearance of the hydraulic arrow is shown in the figure.

Photo 1. The drawing shows a sectional view of the hydraulic separator, with the main components labeled.

What modes are there?

The device is capable of operating differently in various situations, depending on the temperature of the coolant inside:

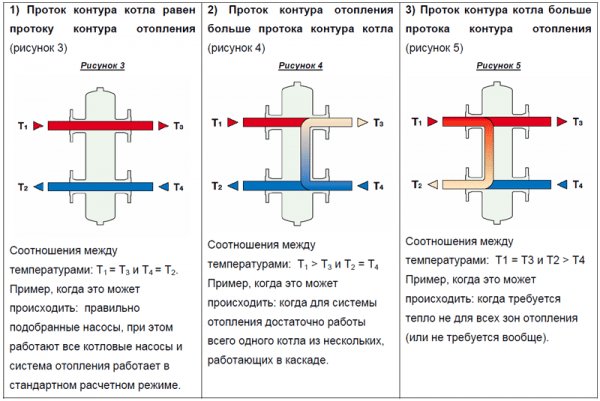

- Standard option — the circuits' flow rates are approximately equal. The system is in relative equilibrium, so hot and cold water flows through the corresponding branches.

- Amount of liquid, leaving the boiler, less than required. Because of this, part of the coolant from the return line does not return to the heater, but repeats a full circle along the piping.

- Third mode is a reflection of the second: the boiler leaves excess of substance. This happens if not all parts of the system require heating at a given moment.

Schemes

More detailed options for operating the hydraulic separator are presented in the figure.

Photo 2. Diagrams of three options for using a hydraulic separator, indicating the characteristic features of the device's operation in each mode.

Advantages

Advantages of a hydraulic separator:

- Alignment exploitation boiler.

- Stabilization coolant flow rate, pressure.

- It's getting better control contours.

- For each part of the harness there is independent heat exchanger, which increases service life.

It is also necessary to note the reduction in requirements for the circulation pump.

What are the additional features for?

In addition to the above, the hydraulic arrow performs two useful functions:

-

Flow of water slows down sharply, getting into the device. Due to this, part of the solid accumulations settles to the bottom with each circle.

They can be easily released using a special valve.

- For the same reason, liquid gas bubbles leave, for the release of which a tap is provided at the top of the device.

How to calculate parameters

For a device, the main indicator is body diameter, which consists from three pipes. The calculation is performed by one of two parameters: maximum throughput or temperature difference.

IN first In this case the formula has the form:

D = 3 * Dp = 18.8 * (G / W)1/2, Where

- Dp — diameter of the branch pipe.

- G — maximum flow.

- W — limitation of the vertical velocity of the coolant.

In second case:

D = 3 * Dp = 17.4 * (G / (W * T))1/2, Where

- T — the difference in temperature between the supply and return.

- All other characteristics have the same designations.

The difference in the formulas is due to the heating of the water. The degree 1/2 denotes the root of a number.

The diameter of the pipe can also be determined:

Dp = ((4 * Q) / (Pi * V))1/2, Where

- Q — maximum coolant flow rate.

- V — fluid velocity in secondary circuits.

- Pi — the number Pi.

Important! The formulas allow you to determine the required size of the hydraulic arrow quite accurately, but you need to choose the device based on diameter of the boiler pipes.

Additional calculation methods

There is also two methods of calculation:

- Practical — by testing several pipes, adjusting them to the contours. The separator must have three times the size, than the one found.

- Quantitative — by the number of branches distributed over the entire height of the device. The distance from the boiler insert is chosen as the main indicator to the first turn.

Manufacturers: photo

Among the companies, it is impossible to identify a clear leader with higher quality products. The following companies are engaged in the creation of hydraulic arrows:

- Immergas.

- Barberi.

- DesignSteel.

- Emmeti.

Photo 3. Brass hydraulic arrow, power 60 kW, dimensions 320×140 mm, manufacturer - "Emmeti, Italy".

- Ariston.

- Askona.

Photo 4. Threaded hydraulic separator, power up to 100 kW, internal thread 1 1/2, manufacturer - "Askon".

- FAR.

- Meibes.

- FORS.

- Others.

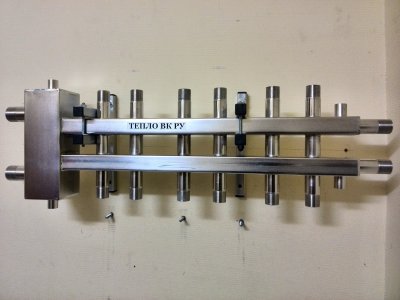

Photo 5. Modular hydraulic arrow-collector Econom-Compact made of stainless steel, power 32 kW, manufacturer - Potok, Russia.

The devices differ price, material, number of branches, weight, diameter of pipes and several other, less important indicators.

Useful video

Check out the video that explains what a hydraulic arrow is and what it is used for.

Installation

Installation of a hydraulic separator is recommended in the following situations:

- The coolant is warming up in three or more boilers.

- The system uses several circulation pumps.

The device helps to regulate the piping with a large number of devices. In most other situations, the hydraulic arrow is not necessary.

Installation is quite simple:

- The installation location ist gap between boiler and collector (if any) or the first branch. Space is required to accommodate all pipes and provide free access to them.

- The device itself is located on brackets, usually vertically. This helps the sludge to fall to the bottom and the air to rise to the top. If the separator has a large mass, it is placed on supports or the floor.

Important! It is important to remember to be careful during installation. It is necessary to get each section of the pipe to the branch pipe, otherwise it will be necessary remake.

- The pipes are connected conventional threaded, Sometimes flange connectionsThe circuits are connected in turn.