Protect the system from unforeseen situations: the operating principle of the heating hydraulic arrow

A hydraulic arrow is a device connected and operating in the heating circuit, directly connected to the boiler.

One of the important purposes of the hydraulic arrow is increase fuel consumption that is not provided for in the boiler, but is required to heat the house.

By installing a hydraulic arrow or a hydraulic separator, users strive to save money without buying or increasing the power of a boiler that is adjusted to the total consumption of water or other liquid.

The hydraulic separator is an artificially created space where consumption can be accelerated, increasing it several times for the heating system. Another equally important purpose is maintaining hydrolytic balance and pressure throughout the system.

Thanks to the hydraulic arrow in the heating circuit the pressure will not jump, disrupting the entire interaction. This feature helps you seamlessly switch heating between different living spaces, for example, turning on the floor only in the kitchen, rather than throughout the entire house.

Content

Description of the device

The device itself looks like an elongated parallelepiped with six different outlets, located opposite each other. Each of these outputs is responsible for a separate function. For example, the highest of 5 valves Allows air to escape from the system without problems, so as not to increase the overall pressure. This happens automatically, the owner does not have to control anything.

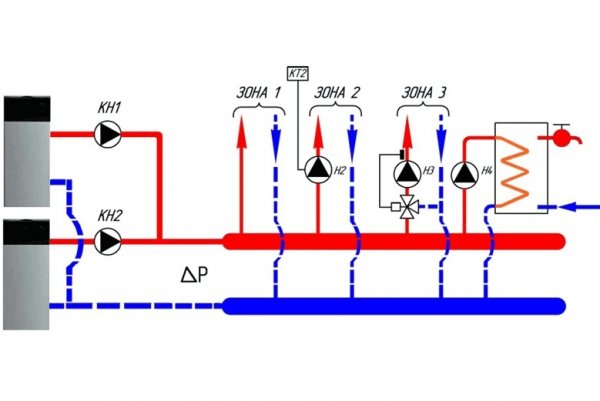

Photo 1. A hydraulic arrow installed in the heating system. The hot coolant is marked in red, the cold one in blue.

The lower branch pipe helps to destroy and remove “garbage”, which remains in the hydraulic separator device. Dirty air from the pipes (its particles) and sediment from the onset of corrosion or another process fall down, where, like a blade, is located the lowest one is the sixth branch pipe. The remaining valves are connected to pipes with water. The entire hydraulic arrow is hollow inside, there is nothing in it except water and decay products.

The principle of operation in the heating system

The hydraulic arrow helps the boiler to which it is directly connected, increase its power and water transfer speed. Why is this necessary? The fact is that when there is a lack of power, but the system is working quickly, the boiler heats up a lot. As a result - heat stroke, i.e. the air starts to push apart the walls of the boiler, and what will happen next is physical damage to the house, the entire heating system and, of course, human health.

Such fluctuations temperature and power only happen in a few cases: the heating mechanism was started for the first time; the heat exchange undergoes a technical check and other work, forcing the circulation pump (“the heart of the entire heating organization”) to be separated from the main circuit or from the hot water source.

Photo 2. Diagram of connecting the hydraulic arrow to the heating system and the principles of movement of the coolant through it.

By installing a hydraulic separator, the user forces air or water to pass through an additional cooling point. Thus, passing through the entire flow of the hydraulic arrow, the hot air splits in half, losing half of its heat. One air flow continues to go into the boiler, and the other down the hydraulic separator tube, adding to the cold impurities of water or gas and cooling down.

And vice versa, if too much cold water comes out of the boiler, then the extra layers have time to warm up, and At the outlet, the consumer receives the required temperature. This is roughly how the whole system works. Now let's look at everything visually.

How does a hydraulic arrow work in different cases?

The operating principle of a hydraulic arrow varies depending on the purpose of its use and the type of systems in which it is installed.

Heating with 4-way mixer

To describe the operation of the heating system with a 4-way mixer, first you need to imagine a square, on each side of which there are holes of equal width. All of these compartments have either cold or hot water flowing out.

In the system There are only 3 modes: fully open, fully closed and in between. Let's start with fully closed.

As we know, warm air or hot water flows come straight out of the boiler, and cold flows come out of the heating system (the water came out of the boiler, made a circle and cooled down).

If the whole system is closed, i.e. it does not work, then warm water constantly overflows through the hydraulic separator, without going anywhere, flowing constantly in one circle and returning back to the boiler.

The same situation occurs with a cold stream of water or air, which does not heat up again, remaining cold until opened. These liquids do not mix and do not transfer heat to each other, circulating strictly along their own contour.

In the intermediate mode, these liquids begin to mix. The temperature is often slightly above average because all the steam accumulated during the closed mode comes out and begins to warm the cold streams. In this way, floors are usually heated so that feet do not burn.

In open mode, the hot and cold water flows do not intersect again., but compensate for each other's losses. What does this mean? Let's imagine a square again. Streams of hot air or water come out of one edge and enter the heating system, while the cold liquid, leaving it, moves towards the boiler, where it warms up. And such a process of constantly replenishing hot water with cold and vice versa is almost a perpetual motion machine, if you do not take into account that the heat is irretrievably lost.

For neutral operating mode

The ideal operating mode of the hydraulic separator is the moment when the amount of hot and cold water is approximately the same and does not require regulation.

This usually happens when the boiler is running continuously and without interruption - very rarely, because there is always an error.

The boiler does not have sufficient power

Based on this problem, a thermal sensor is installed, or, in our case, a hydraulic arrow. Having received a signal from the built-in thermal sensor, the hydraulic separator switches to different modes: either open or closed.

Attention! This ensures boiler safety, which can simply split overnight from temperature and pressure changes. By distilling water, cooling or heating, the hydraulic arrow helps the boiler cope with the thermodynamics balance in order to continue working.

The flow in the primary circuit is larger than the coolant flow rate

As already mentioned above, if the hot stream is too hot to enter the boiler, it is heated through the hydraulic arrow. enters a system that guarantees the flow is divided into two parts, the second will cool down and go into the heating system along with cold water or steam, and the hot part will shrink significantly and will no longer pose a threat to the already hot boiler.

Useful video

Watch the video, which tells you exactly how to make a hydraulic arrow with your own hands.

Relevance of the hydraulic arrow

Such a small but such a necessary thing should be in every home, especially in the countryside, because temperature and pressure fluctuations in megacities and nearby areas fluctuate greatly due to the huge number of people who use them individually.

For example, the neighbor below wanted to turn the radiator up to maximum, and the neighbor above wants to harden himself at home. You can't do without a hydraulic arrow.

The jump in temperatures coming out of the first circuit affects the entire boiler, so buy hydraulic arrows and Protect your life from stupid neighbors and random domestic disasters.