To maintain normal pressure: rules and location of installation of expansion tank in the heating system

Expansion tank (damper) – a necessary element of water heating.

Because liquids tend to expand when heated and remain incompressible, the pressure in the system increases and the water needs to go somewhere.

Damper compensates for the pressure in the system and accumulates temporary excess fluid.

Location of the expansion tank for heating

Heating systems come in open (gravity) and closed (autonomous) types. Due to differences in the operating principle, these systems use different expansion tanks. Depending on the type of heating, the location of the device also changes.

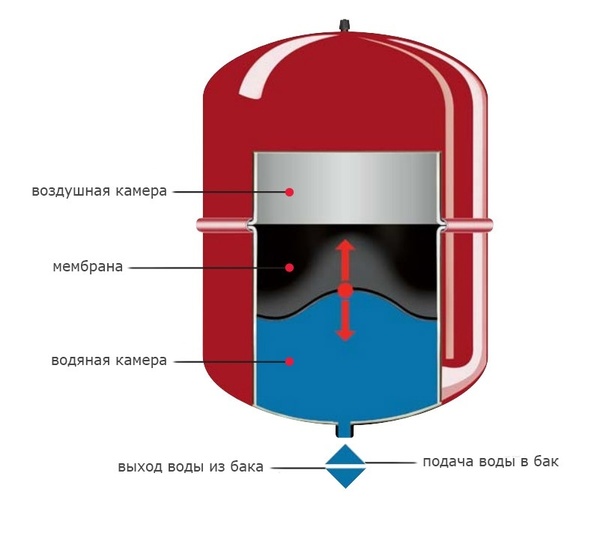

Photo 1. The structure of an expansion tank for heating systems. The arrows show the parts of the structure.

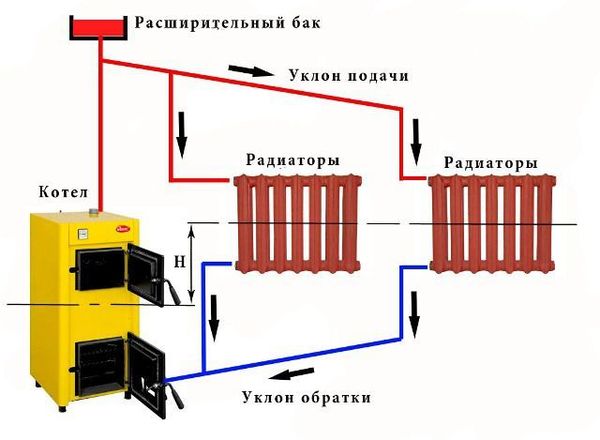

With natural circulation air accumulates at the highest point of the system, and the hydraulic accumulator is installed there. The non-hermetic container allows excess water and trapped air to freely exit.

In case of forced circulation for air removal is provided by special taps. A sealed tank is used to maintain constant pressure in the system. Such heating will function properly at any damper position.

Rules and installation location

Correctly selected and installed device not only compensates for thermal expansion and stabilizes pressure, but also:

- neutralizes the impact of elevated temperatures on equipment;

- increases the service life of all system elements;

- increases reliability and safety.

Attention! The boiler can be a ready-made mini-boiler room with built-in pump and expander. In this case, you just need to make sure that the tank volume is sufficient.

Where to put the device in an open system

Dampers are used for energy-independent heating from steel sheets or polymer materials. The tank is a square or rectangular container equipped with a non-hermetic lid to protect against debris, pipes for connecting heating mains and an outlet pipe.

Photo 2. Diagram of an open heating system. The expansion tank, installed at the highest point of the structure, is marked in red.

Since the walls and seams of the product are in constant contact with moisture and air, they subject to corrosionIt is good if the tank has a drain cock for repair work or replacement of the device.

Installing a tank in an open system is carried out at its highest point. Often the device is installed in the attic. Then it is worth providing a pipe for adding water. It will be necessary to additionally insulate the tank to avoid heat loss. If you place the device on the riser immediately above the boiler, then the temperature of the coolant entering the tank, will always be as high as possible, which can become a source of noise. Therefore, it is better to place the tank on the return stroke.

Important! Expansion tank mounting must be reliable.

How to install in a closed system and where is the best place to install

The device for the energy-dependent system provides complete tightness and presence of a membrane (plate or pear-shaped) that separates the air and water portions of the tank. When water enters, the flat diaphragm stretches toward the air section, increasing the volume of the tank.

In a tank with a pear-shaped membrane, the coolant enters a rubber balloon, which, as it expands, compresses the air around it.

The liquid does not come into contact with the metal, which extends the service life of the product. In addition, the balloon membrane can be replaced if damaged, but the plate membrane cannot.

The position of the tank in space is also important. When liquid enters from below, it is more convenient to drain it from the tank. But air bubbles entering inside will reduce the useful volume. Position the container with the valve facing up This will eliminate it, and the drain will be facilitated by a shut-off valve in front of the device.

It is important to provide for easy access to the damper for subsequent maintenance. If you install the device on the return pipeline, This will avoid excessively high temperatures. And installation to the circulation pump will protect against strong pressure surges.

Useful video

Watch the video to learn how to choose the right expansion tank for your heating system.

How to extend the life of the expansion tank?

The expansion tank is most often fails prematurely due to the following errors:

- due to purchasing a low-quality damper from unreliable sellers;

- due to the installation of the tank with the inlet valve down;

- due to the installation of the device behind the pump;

- due to incorrectly selected volume of the hydraulic accumulator;

- due to the installation of the tank immediately at the outlet of the boiler.

A thoughtful approach to editing will save you from breakdowns and unnecessary expenses. A pressure gauge and manual pressure control valve will help you notice a problem in time and prevent an accident.

Comments