Supply or return - where to install a circulation pump in a heating system?

Circulation pump improves the operation of heating systems.

The presence of such a device in the circuit will provide the ability to regulate the temperature in the premises and increase heat transfer.

Most of the devices are arranged quite simply, allowing homeowners to install them themselves.

Functionality of the circulation pump in the heating system

The purpose is to accelerate and regulate the movement of the coolant flow in the circuit:

- in systems with forced circulation (especially if the supply goes to two or more floors);

- in systems designed for natural circulation, it significantly increases the heating efficiency.

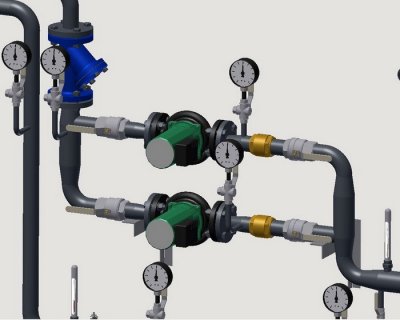

Photo 1. Circulation pump model UPS 32-100 with wet rotor, manufacturer - Grundfos, Denmark.

In private homes, a device with a wet rotor is usually installed:

- silent;

- not requiring maintenance;

- With economical energy consumption.

For long circuits and systems serving multi-story buildings, devices are purchased with dry rotor, powerful, with high efficiency.

Such devices require regular inspection and maintenance. They have to be installed in special rooms or where their noise will not disturb.

What to consider when choosing the right location

When installing the device in the circuit, the following is taken into account:

- correct orientation (indicated in the instructions, horizontally or vertically);

- correct binding (a correctly selected set of additional devices);

- if present two or more branches, then the best option is to install a separate pump for each (in this case, it is possible to immediately achieve an equal temperature in the rooms along each branch and use fuel more economically).

Where is it better to install: supply or return

Professionals recommend installing the pump before the first branch of the circuit. The device is designed for the temperature of the liquid being pumped. up to 115°C, therefore, the choice of supply or return pipe is not fundamental.

This is significant when installed in a system with a steam boiler, since the coolant at the outlet has a temperature above 100°C, which is unacceptable. The temperature on the return flow pipe is set within the normal range.

Return — the only option for boilers on solid fuel except for systems with automated control.

Important! Boilers without automatic control often overheat the coolant to boiling, so steam gets into the pump installed in the feed. This leads to an almost complete stop of the liquid movement along the circuit and an emergency situation, even explosion.

The return pump may also be full. ferry, but in this case the response time of the safety valve increases, which allows you to solve the problem and avoid disaster.

Where to install the pump: diagrams

Standard circuits for connecting a circulation device have been developed for various systems. The following important points are taken into account:

- Ease in maintenance (convenient approach to it).

- When installed on feed, its position should be after the boiler and safety unit.

- For convenient control it is necessary to install it with shut-off valves (they are closed and the device can be safely removed from the pipes without draining the entire system).

- When installed on the return line, the pump position is — in front of the boiler or between the expansion tank and the boiler.

- It is necessary to install it before the unit coarse filter, this will prevent the impeller from jamming (some models are sold with a filter already installed).

- Most boilers are working regardless of the availability of electricity, therefore, the heating system is initially designed with the possibility of natural circulation in case of a power failure (the pump is installed on a parallel branch that can be disconnected from the system).

- The device is installed in a system with a solid fuel boiler. to the return feed line. The connection is made with a bypass.

How the pump should stand: installation process

How to install:

- should be secured union nuts;

- find out how it works in each of provisions (vertical and horizontal);

- installation is in progress on any section of the pipeline, but the rotor axis is located only horizontally;

- the contacts for connection to the electrical network are positioned so that they are not flooded with water (unfolds by loosening the mounting screws);

- indicated on the body flow direction - it is necessarily observed.

Installation involves the sequential placement of the necessary components, without which the pump will fail.

Shut-off valves (put from both sides, if necessary, the section with the pump is disconnected from the system).

It is envisaged separate branch for the pump (bypass), this will allow you to use natural circulation.

Additional elements:

- coarse filter (placed in front of the pump);

- check valve (needed in systems with an expansion tank or when installing two pumps);

- air valve for removing air from pipes (in some models it is built in initially, then it is not needed in the chain).

One pump enough for the system with one boiler, additional devices are installed if:

- two or more boilers;

- complex circuit branches;

- installed buffer capacity;

- with a large length of the contour (several floors);

- at "warm floor" system;

- There is two or more boilers with different types of fuel;

- installed heat accumulator (additional capacity in which the liquid is cooled and supplied to the system when necessary);

- pumping devices are installed on bypass, which will allow you to use natural circulation.

Attention! A separate cable with a circuit breaker is laid for the pump. It is not recommended to simply plug it into a regular outlet. For safety, there should be grounding and a circuit breaker that trips when there are power surges.

Useful video

Check out the video that explains the different installation schemes for a circulation pump.

Is it possible to install it yourself?

It should not be forgotten that if the installation rules are not followed, in the best case, you will have to do without heating, in the worst case, an accident may occur.

Therefore, the manufacturer's recommendations, requirements for safe network connection and device installation rules must be followed.