If something goes wrong, the entire structure will suffer! Installing a pump in a private home heating system

Circulation pump serves to force the flow of liquid through the piping.

In some cases, it also regulates the temperature. Most heating systems require the installation of circulation pumps.

Content

- Where to place the device on the heating system

- How to install a pump with your own hands in a private house

- The need for water filtration

- Location of the pump in the heating circuit with the boiler

- Bypass purpose

- Electrical connection principle

- Checking and starting operation

- Useful video

- General recommendations for setting up

Where to place the device on the heating system

It doesn't matter what pipeline, since the device maintains high liquid heating. The same applies to hydraulics.

Perform the installation in the area near the boiler, before the system branches. Usually, the return line is chosen, since in such a case the risks are minimal.

If the heating is divided into two circuits (left and right or by floors), it is better to install a pump for each. This will expand the possibilities and allow you to control a separate section of the building, which leads to resource savings.

How to install a pump with your own hands in a private house

One of the most important points is the direction of the rotor. If the installation is vertical, the system will almost certainly have to be redone. And also take into account the flow of liquid through the pipes. There is an arrow on the device for this.

The installation principle does not matter. Study the instructions for the possibility of use in certain circuits. When choosing, take into account the power drop when installing the pump not horizontally.

Correct installation diagram

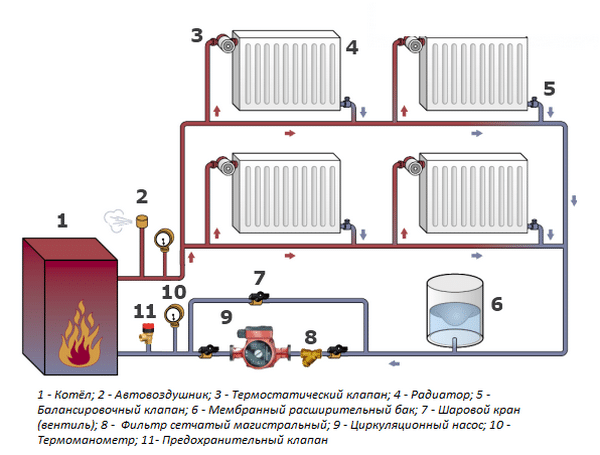

A pump installation on a bypass is often used.. It allows the system to operate during power outages. It also addresses the occurrence of malfunctions with the circulator, allowing replacement of parts without draining the water.

Photo 1. Heating system diagram. The number nine indicates the installation location of the circulation pump.

For installation you will need:

- pump;

- union nuts or flange connections (included);

- filter;

- shut-off valves;

- bypass and valve for it.

Some space will be required for installation. Depending on the building's features, Project development may be required.

When creating a piping system with forced water circulation It is recommended to install a special section of pipe designed for the pump. They are not common, but they make the work much easier. For the same reason, you should look for an assembled device. Otherwise, you will have to invite a specialist or do the process yourself. The assembly principle depends on the fasteners and material. The latter divides devices into two types: metal, requiring complex welding, and plastic.

Installation rarely takes more than an hour. This does not apply to steel pipes, which require the creation of complex connections. When installing, do not make a mistake with the calculations of lengths. The work consists of the following:

- Preparation: selection of components and their purchase.

- Selection of tools: You will need keys, sealant, and possibly a welding machine.

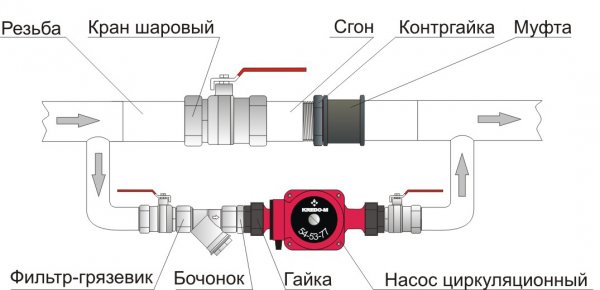

- First, three units are packed onto the tow: two for the pump and one for the tap. The first ones are distinguished by the presence of a filter. The latter is placed at the bottom, combining the branch pipe and the coupling. It is applied, marking the installation location. And the joint points are also thought out.

- Then assemble the loop without tightening the nuts completely. At this stage, measurements are taken to determine the characteristics of the unit.

- The cut parts of the pipeline are placed along the common axis on arbitrary stops. The loop is tightened, then the structure is welded. Before the next step, it is recommended to remove the pump so as not to damage it.

- The bottom is secured by joining the coupling. Having packed the last one, the pump is returned to its place. The rotor is aligned along the horizontal axis. The nuts are tightened, fixing the position of the structure. The joints are coated with sealant and they move on to the electrical part of the process, if required.

After finishing the installation, you cannot immediately do a check. First, the piping is filled with coolant. To prevent air from collecting in the loop at this time, open the tap. This step is optional if there is a gas outlet. When water starts flowing from the hole, it is closed. Having completely filled the pipes, repeat the procedure. Then everything is tightened again, lubricated with sealant and put into operation.

The need for water filtration

A mud trap is often placed in front of the pump, the purpose of which is to prevent solid particles accumulated in the coolant from passing through. It is enough to use standard coarse cleaning device, since the pipes have a small diameter.

Photo 2. Diagram of pump installation in the heating system. The arrow indicates the location of the mud filter.

The collection barrel is placed downwards, which will prevent possible malfunctions.

Attention! It says on the filter direction of water flow. If you don’t follow it, you will have to change the part more often.

Location of the pump in the heating circuit with the boiler

Depends on the project. The development should be entrusted to specialists to prevent possible malfunctions. It is usually placed at the bottom of the pipeline, near the boiler. For stable operation, follow one rule: Mount the device before or after all branches.

Bypass purpose

The device is a shut-off valve that serves to increase hydraulic resistance. This allows the system to operate without power supply. The open valve has the same throughput as a pipeline, so the efficiency does not drop.

Photo 3. Bypass on which the pumping device is installed. There are several valves on the structure.

Electrical connection principle

Circulation pumps operate from the mains 220 volts. Use a regular connection, but a dedicated line is recommended. You will need 3 wires, plug and socket into three contacts. Power can also be provided directly via terminals. The latter are placed under the cover to the corresponding letters, and the wires are separated by color. N — zero, completely or partially blue. Grounding has a special symbol, green, sometimes combined with yellow. L — phase, almost any color (except those mentioned above).

Having created the connection, the mounting box is closed and tightened with a screw.. Depending on the manufacturer, sometimes sealant treatment is required. The cable should be long enough to reach the power connectors.

The operation of the entire system depends on the condition of the pump, so it is recommended to make a backup power supply. Usually, the stabilizer is placed on batteries. Even automatic heating will consume no more than 300 W, so it is enough to purchase the device at 400-450 W. And also take into account the capacity of the batteries.

Checking and starting operation

After completing the installation, fill the system with coolant, clearing the pipes of air. When all gases have been removed, conduct a test launch. If no problems are found, proceed to full-fledged work. Otherwise, repeat the flushing.

Useful video

Watch the video, which tells how and where it is best to install a circulation pump for heating systems.

General recommendations for setting up

Most pumps come with factory settings. These do not necessarily need to be changed, but depending on the system, it may be necessary. For consultation, invite a specialist, who will make changes manually if necessary.