If the circulation pump for heating is faulty: how can you repair it yourself?

For successful repair of any equipment it is necessary to know its internal structure.

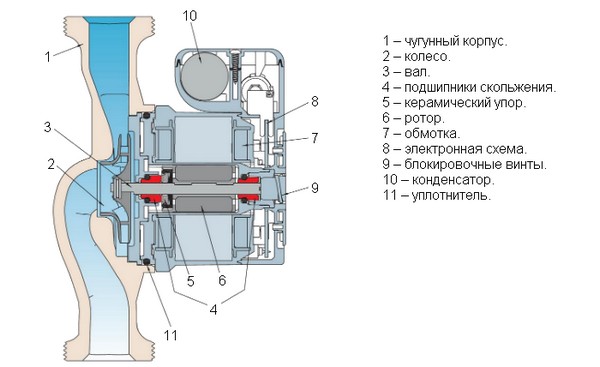

The circulation pump consists of many parts.

There are various types of breakdowns, which suggest different ways of repairing them.

Content

Circulation pump device for heating

Main details:

- Metal case, inside which the operating units are located. Stainless steel, aluminum or various alloys are used in the manufacture of the body.

- Electric motor — the main part of the pump.

- Impeller, which is a wheel with blades. It is installed on the rotor and ensures the pumping of the heat-transfer fluid. Most often, the impeller is made of polymer.

Photo 1. The diagram shows the structure of the circulation pump: all the most important parts are indicated.

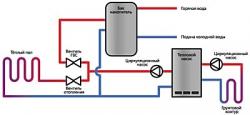

Circulation in the circuit occurs when the rotor rotates with the help of electric motor. The rotating blades push the incoming liquid further into the pump, blower boy. Widely distributed two types of pumps:

- Wet — are used for domestic heating systems. During operation, their rotor is in liquid, which ensures constant lubrication and timely cooling of moving elements.

- Dry — are found in large and medium-sized boiler houses, and are also used to heat large areas. The engine with a dry-type rotor is placed in a separate block, and the rotation is transmitted to the blades using a special clutch.

Main faults and their repair by yourself

Many pump malfunctions are typical and will require repairs to fix them. minimal knowledgeRepair work must be carried out with the power supply turned off.

Important! If the pump is still on guarantees, try to contact specialized services to fix the problem service centers.

Below are the signs of the most common problems and how to fix them yourself.

The pump hums and pumps poorly: how to repair it?

If after a long period of inactivity, when you turn on the heating equipment, you hear a humming sound, then the cause of the malfunction is shaft oxidation.

To restore functionality:

- turn off the power;

- remove water from equipment;

- dismantle engine;

- turn the rotor by any available means.

Sometimes the cause of the problem may be something stuck inside foreign object. To remove it after turning off the power and removing the water, remove the screws that fix the case. Avoiding a repeat of the emergency will help installation of a mesh filter at the pump inlet.

Why is there no hum and rotation?

Check the power supply, for this use tester. Replace the blown fuse. Check the correct connection. terminals.

Does not start or stops after starting

Leads to stops limescale, accumulated inside the device, it will need to be removed.

Switching on is accompanied by a loud noise

Accumulated air in the heating system manifests itself in the form of loud noises.

Bleed the air out heating circuit.

To prevent the problem in the future, provide for it in the pipeline special node.

Strong vibration

Wear impeller bearing manifests itself in the form of vibrations. The part needs to be replaced.

Insufficient pressure

There are several possible reasons for this problem:

- Incorrect direction of rotation of the blades due to broken phasing. To troubleshoot, check the phase connection and correct it.

- Increased viscosity of the heat transfer fluid. To increase the pressure, pay attention to the cleanliness of the inlet filters. Check whether the parameters of the pipeline inlet correspond to the pump settings.

Stop after start

Make sure it is correct phase connection, fuse contacts, cleanliness of clamps. Correct any deficiencies found.

How to disassemble the device

Preparatory stage of disassembling the pump - dismantling:

- Necessarily turn off the power supply.

- When removing the pump from the heating circuit, use the provided bypass heating pipe.

- If a long repair is expected, connect spare pump unit.

- The pump can be removed after unscrewing the shut-off valves.

Stages of equipment disassembly:

- The pump cover is removed. If the bolts that fix it are "stuck", a special aerosol will help to unscrew them. You can buy it in specialized stores.

- It is taken out of the case rotor with impeller. To remove it, unscrew the mounting bolts or fasteners.

- Replace faulty unit.

How to clean parts

Pump blockage is caused by accumulated limescale deposits. Excessive contamination can cause the heating unit to malfunction. complete failure. Small deposits on the shaft can be removed independently using a regular vinegar essence.

To clean the inside of the pump from dirt, dilute it water 1:1Pour the resulting solution into the pump through one of the fastening connections.

In a day The limescale deposits will partially dissolve, and to remove the residue, disassemble the unit and clean it thoroughly.

Clean the inside of the pump carefully, removing any remaining deposits from all surfaces, using with a wooden spatula. Finish the treatment by sanding, which can be done with a piece of cloth or a special paste.

How to lubricate a pump

Tightness is essential for proper operation of the equipment. To avoid parts drying out during a break in operation, preservative lubricant, which is applied to the gaskets and inlet and outlet pipes.

Prevention and diagnostics of breakdowns

Simple preventive measures will help to increase the service life of heating equipment:

- It is prohibited turning on the pump without water.

- To prevent oxidation of parts, turn on the equipment when not in use. once a month for 15-20 minutes.

- Conduct regularly visual inspection, be attentive to any noises, excessive heating of devices, or leaks.

Before the start of a new heating season, a technical inspection of the equipment is carried out. Conduct a test run and check the condition of the most important units:

- correct connection to the pipeline;

- tightness of connecting elements;

- filter condition.

Useful video

Check out this video on how to disassemble a wet rotor pump from the manufacturer "Wilo".

Summary: If Nothing Works

Try to delete quickly malfunctions when they appear. If the equipment needs major repairs, carry out a preliminary financial calculation.

Attention! Trade policies of many manufacturers equipment is aimed at actively supporting sales, and original parts for repair difficult to acquire.

So sometimes it's cheaper to buy a new one pump, than to repair the old one.