The mechanism has started to "act up"? It's time for repairs: how to disassemble a heating circulation pump with your own hands

Modern water heating systems cannot operate without equipment, controlling the correct flow of water in the pipes. This task is handled by a circulation pump, which moves the coolant through the pipes.

There are problems with the operation of the device that need to be fixed in a timely manner. Troubleshooting device, you can carry out at home, having previously carried out dismantling and disassembling. More on this later, in more detail.

Types of heating circulation pumps and operating principle

Circulation pumps in municipal or domestic heating systems are two types: with dry and wet rotor. Although they are identical in principle of operation, first the option has Efficiency 70%.

It is more appropriate to use it in communal and industrial premises. Such a device less durable, overheats more.

That's why equipped with a fan and requires additional maintenance. For domestic purposes, they use a wet rotor, which is easier to operate. After all, its engine is washed by cold water and cools it without any additional elements.

The operating principle of such a pump is based on pumping water from one point to another. On the rotor of the device, there is impeller (a wheel with polymer blades), which, rotating, picks up water entering the inlet, accelerates it (if used for domestic purposes, the speed can reach 2 m/s) and pushes it out into the outlet. The dynamics of the coolant movement can be adjusted using switch, which is located on the pump body.

Important! In houses with large footage, the heating system should provide warm temperature in all roomsTherefore, introducing equipment into the system that will significantly increase the pressure and, by moving the water evenly, heat all the batteries, will be the right decision.

What to check before disassembling the pump for safety

The circulation pump facilitates fast, uniform heating and helps save gas consumptionHowever, prolonged or improper use leads to malfunctions.

However, some of them can be fixed on your own. Before taking any action to dismantle unit, it is worth checking it. Perhaps the malfunction can be fixed on the spot. Therefore, first it is necessary to:

- Check the power supply to the pump terminals. If such a malfunction occurs, the electric motor will only hum and the rotor will not start.

To fix the problem, contact connection points are checked, and also integrity of wires.

- Check if the shaft is jammed. This can happen due to pollutants, precipitated during the process of water distillation, which occurs due to its circulation and heating in the heating system. Excess particles settle, including on the rotor shaft, which leads to jamming. The problem is fixed with a screwdriver. It is enough to turn the shaft (the location of the spline, the end part of the mechanism), and the pump should resume operation.

If after removing the above faults the problem remains, you will have to dismantle the pump from the main line. However, before disassembling it, it is worth checking whether it is possible to do this - There are types that cannot be disassembled.

How to disassemble and assemble with your own hands

In order to disassemble the device and, if possible, eliminate the internal malfunction with your own hands, you should carry out dismantling. It won't be difficult.

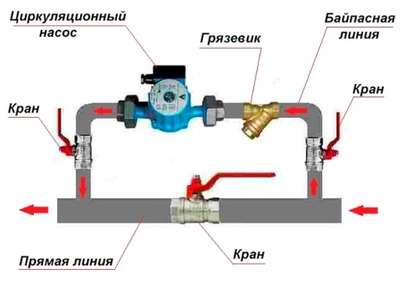

First the device de-energizes, bypass is closed (bypass heating pipe), if any. Then, all shut-off valves are unscrewed, and the pump is removed.

After dismantling, you can begin to disassemble the pump. To do this, you should:

- Unscrew 4 bolts with a wrench, with hexagonal heads that screw the lower and upper parts of the device. If the fasteners are stuck and do not unscrew, it is worth using softening agent "liquid key". After applying this substance to problem areas, already in 10-15 minutes any bolt will unscrew.

- Remove the top part of the housing and take out the rotor., located in the stator cup. Between the rotor wheel and the cup, there is 4 drainage holes. You need to use a screwdriver to pry the wheel through them and pull out the part. If there is a coating that prevents extraction, you can use the softening agent again.

- After removing the rotor, conduct diagnostics, and, if possible, eliminate all problems that prevent the pump from operating normally.

Malfunctions inside the circulation pump system can be of varying severity, for example: if at startup after a few seconds the pump stops working, perhaps the matter is in the long-term operation of the device. Over time, scale forms, which leads to jamming of the rotating units and prevents the rotor from rotating. Therefore, after disassembling the pump, all the limescale is cleaned out, and the fastening joints are lubricated with oil.

At the back of the pump, the cochlear cavity is examined. If it is dirty, clean it thoroughly. Check rubber gasket at the junction of the rear and front parts of the pump housing. If it is unusable, replace the worn seal.

Photo 1. Diagram of the internal structure of the heating circulation pump. The main parts of the mechanism are indicated.

After the faults have been corrected, the rotor is placed back into the sleeve. Then, a rubber seal is placed, the rear part of the pump (snail) is put on, and the fastening screws are tightened. Guided by the arrow on the body, indicating the direction of flow, pump connects to the pipe. The power supply wires are in the correct order, connected to the terminal blocks, and the device is ready for operation.

Important! Before starting the pump, to prevent air lock, Slowly unscrew the screw on the front of the case pump, and let the air outWhen water starts to flow out of the hole, tighten the screw back tightly.

Useful video

Watch the video, which shows how to disassemble the circulation pump and lists possible faults.

Timely prevention is the key to longevity

You can eliminate minor faults that interfere with the operation of the circulation pump yourself at home. Therefore, so that small troubles don't turn into big ones — perform preventive maintenance of the equipment more often. If there are suspicious sounds and failures during rotation, disassemble, lubricate all rotating elements, descale and other settling particles. With this approach, the pumping equipment in the heating system will last for decades, providing the optimum temperature.