A supply of hot water that is always at hand: how does an electric water heater for heating work?

Electric boiler is a storage type water heater. They are produced in several types., each of whom has minor advantages over their colleagues.

Different boilers differ in the materials used in their creation.

Construction of electric boilers

The device is a thermos and consists of the following components:

- body with fastening device;

- tank;

- thermal insulation between the container and the walls of the device;

- heating element in the form of a tube;

- thermostat to regulate temperature;

- fuse;

- protective anode;

- scheme control and indication.

Distinctive features of a flow-through water heater

The basis of work is as follows:

- Installed device plug into the socket.

- The liquid goes through the boiler into the pipes, heating up along the way.

- Regardless of the connection location, the temperature in the rooms begins to increase.

Powerful heating elements increase the temperature up to 50-60 °C, which is enough for most buildings.

Selecting a water heater by components

First of all, you need to focus on the purpose for which the device is purchased. The power should be in the range from 1 to 15 kW. And the tank volume is also important. You should consult with specialists: a plumber and an electrician.

Power of heating elements

The tubular electric heater is the main component of the system. It It is a spiral with metal wrapped around it. The mechanism is filled with a dielectric, such as sand.

Some devices include several thermoelements. They are used when it is necessary to periodically heat large volumes. Such devices are more expensive, but consume less fuel.

The power should be selected depending on the need. For private use it is enough to use Heating elements from 1 to 6 kW. This is enough to warm up the heating medium and water in the taps.

Important! It should be noted that more powerful devices require more resources.

The devices are divided into two types: open and closed. First interacts with water directly. It quickly becomes coated with lime, is subject to corrosion, therefore it is cheap and lasts less than the second. Second are chosen more often because they include a protective layer, which reduces wear and increases safety of use.

Tank capacity

The tank is one of the most important elements of the boiler. Its size should be: V = T * N / (t1-t2), Where:

- V — the desired value.

- T — the time it takes for the water to heat up.

- N — power, kW/hour.

- t1, t2 — thermal regime of the system.

In addition, when choosing a tank, you need to consider the material from which it is made, the coating of the walls. High-quality device capable of operating for up to 10 years at high temperatures. And you also need to consider thermal insulation. Several layers of the latter increase the cooling time of the liquid to several hours.

Installing a boiler instead of a boiler

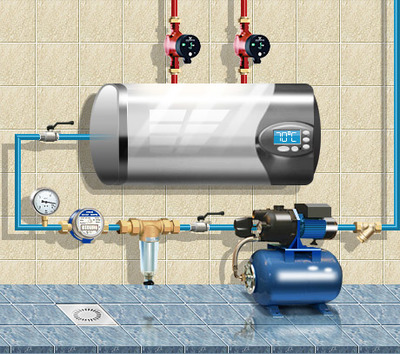

Depends on the form and method. Water heaters They can be oval or rectangular, which affects the placement location. The installation is divided into horizontal and vertical, wall and floorSometimes a thermometer and control system are attached to the outer part of the device.

Fastening is carried out by special mechanisms to the selected surface. Boilers are sold as one piece, so you don't need to think about assembly.

The complexity of setup depends on the model. For simple devices, you need to select thermostats and regulators. In expensive devices, such systems are built-in.

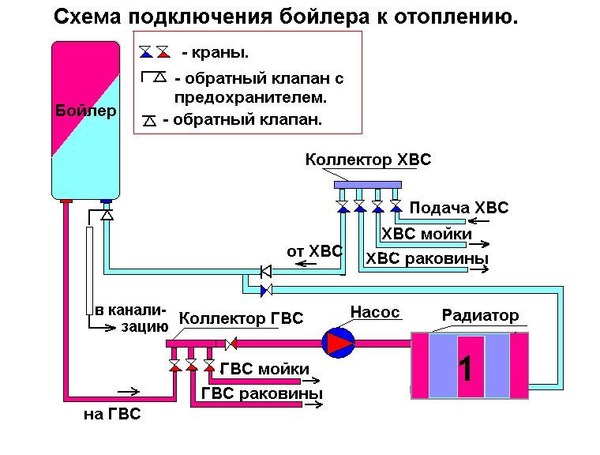

Photo 1. Detailed diagram of the installation of a boiler with a manifold for heating and water supply, indicating the location of the taps.

Features of operation

The boilers work by exposure to multiple layers of working fluid. The device transfers warm water from the top of the tank to the piping, and cold water - down, for heating. And the device also has a divider, separating flows of different temperatures.

Water is heated by heating elements, and thermostats monitor the process, providing readings to the owner. When the required level is reached, the electrical circuit is opened. To maintain temperature, if there are several mechanisms present, one works, in other cases the others are connected.

High consumption of hot liquid leads to a decrease in the volume of coolant in the boiler, which affects the quality of heating.

Important! In some cases the thermostat gives failure that causes boiling water to accumulateBecause of this, the pressure increases, leading the system to an emergency condition.

For protection, a fuse is used, which is placed on the cold liquid tube. It is periodically opened, dumping the latter into the main line.

Heating requirements

The source of water is not important. Most devices can be connected to any type of pipes. The same applies to the heating element, for which the type of fuel is not important.

An expander must be placed at the outlet of the mechanism. Its volume is not less than 10% from the size of the device's capacity. The tank's task is to protect against thermal expansion.

Each branch of the harness must be installed ball valve, which allows you to turn off a separate component of the system for repair. The pipes are placed check valves. Their purpose is to protect the piping from backflow. The presence of such mechanisms allows you to turn on indirect heating device, increasing the speed of work.

Useful video

Watch the video, which shows the diagrams and installation of a boiler for the heating system of a private house.

Practicality of boilers for a private house

Unlike other heating systems, this one uses only electricity. Devices rarely break down and installation is easy in a large number of places. And it should also be noted low cost.