How practical is it to use a boiler for heating a private home?

A boiler is used to heat small private houses and summer cottages.

This option is profitable efficiency and minimal financial costs.

Moreover, you can make a water heater with your own hands.

Content

Can a hot water boiler be used in a heating system?

In order to fully understand what this device is, it is necessary to understand all nuances.

What is the device?

Visually, the heating boiler looks like this the capacity is quite large. There is a heat source inside or underneath it.

Design and technical characteristics

The outer casing of the device contains pressure sensor and electro-mechanical system for boiler control. Next comes a layer of thermal insulation that separates the body wall and the storage tank, and allows you to retain heat.

Photo 1. Indirect heating boiler model 702.1, capacity - 712 l, manufacturer - "Elitec", Italy.

It is advisable to choose the volume of the storage tank in which the water will accumulate and heat up in the range of 200-300 liters. Lower tank capacity values should not be considered, as this will not be enough to heat even a small area.

Water heating is carried out using a tubular electric heater. with a capacity of at least 8-12 kW.

Attention! Important take this indicator into account, since if it is lower, the equipment will not cope with heating, and there will be a need in round-the-clock operation of the device.

What is it for?

Once the storage tank is filled, the heating elements located inside it begin to heat the water. to the set temperature. As the required temperature in degrees is reached, the liquid begins to flow through the pipes into the main heating system pipes.

Although operating principle boiler for heating is quite simple, it is important to remember the features of the preparatory process:

- create circuit with closed-loop circulation;

- foresee the possibility adding liquid into the coolant from water supply systems;

- install pump, regulating the stable movement of water through pipes, shut-off valves, expansion tank;

- to establish water filtration structure, the liquid must circulate through the circuit in a purified form, without impurities.

The heating elements built into the boiler control fluctuations in the temperature of the device. As soon as the user-defined value in degrees is reached, the system automatically switches off. If the water cools down, the reverse process occurs: its heating starts again.

Peculiarities

Unlike conventional water heating devices, this device inlet pipe (for cold water) is mounted down storage tank, and on the way out (for hot) - above.

Thus, the liquid must circulate in the closed heating circuit fixed temperature, which is achieved at the top of the tank.

Indirect heating boiler with connection to the boiler

The main difference between such a device and a conventional water heater for heating is the presence external source of heating the coolant. This could be solar panels, a boiler, central heating.

From such an auxiliary source, heat flows through a coil running along the inside of the boiler. coolant, which, in turn, heats the liquid in the tank.

This system is protected heat-insulating layer.

Installation

Before the main process, it is important to carry out preparatory work:

- provide indoors optimal temperature and humidity level;

- use distilled water — the best option for a coolant;

- uninterruptible electricity supply.

After this, the process of installing a heating boiler is carried out:

- choosing a place for storage capacity, To prevent it from coming into contact with the concrete floor, it is best to install a small platform under the tank;

- installation check horizontal level, there can be no errors;

- connection to the heating system: the diameter of all pipes should not differ;

- The outer casing of the installation is necessary insulate, if the room selected for installation of the boiler is not heated;

- connection to Hot water supply.

Before starting the system, it is necessary to check all connections for leaks.

Wiring diagram

There are several of them:

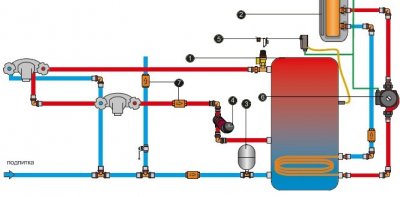

- Through three-way valve, which responds to the signal from the thermostat of the unit. When the temperature in the DHW system drops, switching occurs, and the coolant is directed from the boiler to the circuit of the storage tank. After the required temperature is reached, the thermostat returns to its original position.

- Two-pump system. The point of such a connection is parallel operation. two pumps: heating and hot water supply. Switching from one to another occurs on the signal of the same thermostat sensor. When it works one pump, the second is blocked by a valve.

- Activation of the hydraulic arrow. This multi-circuit system is relevant when using several heating branches.

- Recirculation in the DHW systemThis scheme implies the presence of third entrance into the boiler's storage tank. This way, hot water will always flow to the area where it is consumed when the tap is opened.

What criteria should I use to choose?

Exists 3 main criteria of this process:

- Volume. You should not install the maximum device for this value. This may lead to financial difficulties in the future. Since more water will be spent on a tank of sufficient volume, the bill for its consumption will be higher. It is worth remembering that the larger the volume of the installation, the more it will come into contact with the coil, which can lead to heating of the coolant.

- Power. This criterion affects the heating of water. For a full heating process, a water heater with an indicator of 8-12 kW.

- DiameterThis criterion depends on the area of the room where the device is installed.

How to make a water heater with your own hands

The price range of boilers on the market is quite large. You don't have to resort to it if you do this installation yourself.

Required tools:

- angle grinder;

- electric drill with a drill bit for metal;

- argon arc welding machine;

- spanners;

- grinding and polishing disc for metal;

- sandpaper.

At the same time as a tank better to use capacity from steel. Make special holes in it for future inlet and outlet pipes.

Copper is suitable for the coil - a material with good heat transfer. Thermal insulation layer better to form thickness about 5 cm of glass wool or basalt insulation.

Installation

Once the components are ready, the device is installed.

Sequence of actions:

- determining the location for storage capacity;

- alignment installation with horizontal level;

- connection of the structure with heating system;

- its connection to Hot water supply.

Before starting the system, it is imperative to check all connections.

Features of use in a private home

To increase the efficiency of the process: heating and supplying hot water from the tap and heating the rooms, an indirect heating boiler is installed in conjunction with a gas boiler.

This solution allows for the immediate supply of warm water at several water intake points.

The installation scheme is no different from the standard one. The only difference is that it is necessary to connect to both the heating and water supply systems. Insertion point should be before the water outlet mark, after the toilet.

All necessary recommendations are given by professional craftsmen.

Useful video

Check out this video that discusses the advantages and disadvantages of using a boiler in your heating system.

Maintenance: After how long will it need to be disassembled and cleaned?

Annually in the water heater replace the anode, since it doesn’t work any longer. At least twice a year necessary remove parts with complete depressurization of the entire system for cleaningThis is done manually and using special chemical solutions.