Myths and reality: how economical are induction boilers for heating a private home?

Electric boilers for heating systems are not very popular among consumers due to the following reason: high cost of electricity. But they are bought because not all villages and cities have alternative solutions.

Electric boilers do not differ in variety; there are only a few on the market There are two types: heating elements and induction ones.

The latter are used in industry. Domestic boilers were presented in the 90s, and during their time twenty years of operation The devices have undergone a number of changes. Although the operating principle remains the same.

Content

What is an induction electric boiler?

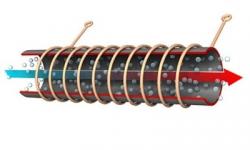

The design of the induction boiler consists of:

- from a housing in the form of a cylinder sealed on both sides, made of shielded and insulated material;

- cartridges, inserted into the housing and made of dielectric;

- pipes, inserted into a sleeve and made of a special alloy (steel can be used);

- a copper busbar is wound onto a spiral-shaped sleeve, which is connected to the power supply.

It's made in the case two holes, to which the pipes are welded: the lower one for the inlet of cold water, the upper one for the outlet of heated water.

Operating principle

The principle of electromagnetic induction in 1831 the English physicist noted Michael Faraday. At the beginning of the twentieth century, his postulate was introduced into production in the form of a heating element for melting metals. It turns out that induction boilers have been known for a very long time, and they were used, but only at the production level.

The principle of electromagnetic induction is based on on the formation of an electromagnetic field, which heats up any ferromagnetic material (to which a magnet sticks) if you place it in the center of this field. It is not difficult to create an electromagnetic field. To do this, you need a coil, preferably made of copper wire, to which voltage is applied. It is inside the coil that the magnetic field is formed.

Installed inside dielectric pipe (not allowing electric current to pass through), a coil is wound around, a steel rod is installed inside.

If you install it, for example, steel rod, then it will necessarily heat up to high temperatures. It is on this principle that the design of the induction heating boiler is built.

And through the inner cavity of the pipe, washing the rod, the coolant (water or antifreeze) flows. The rod, heated by the electromagnetic field, transfers heat to the coolant.

There is one subtle point in the operation of induction boilers that is tied to Joule-Lenz law. If you increase the resistance of the rod, you can increase its heating. And the increase is carried out in two ways:

- increase the length and decrease the cross-section;

- make it from a metal with high resistivity, for example, from nichrome.

Reference! These methods are used either separately or in combination. This is the way power is controlled boiler.

Criteria for choosing an electric boiler for heating a private house

There is a large amount of different information that highlights induction electric boilers as the best in the category of electric heating elements. But not everything in it is true.

Equipment safety

Any induction electric boiler that is used to heat liquids, is dangerous. Because water leaks, which cannot be avoided during long-term and intensive use of induction or heating element boilers, will cause a short circuit.

This concerns the electric current directly. Besides, leakage is a common cause of electric shock people who, due to ignorance, came into contact with the boiler body.

Photo 1. Induction electric wall-mounted boiler Ineri SAV, installed indoors. Takes up little space.

Both heating element units and induction units are in equal positions here. Manufacturers of electric boilers for heating systems try to improve the quality of assembly, increase the tightness of joints, minimizing the possibility of coolant leaks. That is why The experts recommend not to buy homemade ones induction boilers and do not try to make them yourself.

Like all high-power induction electric units, induction heating boilers must be connected to the power supply network only through safety elements: automatic machines, residual current device. It is very important to maintain an exact ratio between the cross-section of the wiring and the boiler power.

If the electrical wiring in a private house does not correspond to the device being installed according to this parameter, then it is better to conduct it to it separate electrical circuit from the distribution board.

Attention! Today, power surges are not uncommon in private homes. An induction boiler, in principle, like a heating element boiler, reacts sharply to power surges, reducing the quality of work. Therefore, it is recommended to install voltage stabilizer or for the whole house, which is very expensive, or at least for the boiler itself.

The best solution is to buy an induction boiler from a well-known manufacturer. The brand itself is a guarantee of quality. It would be nice if the region where the induction boiler is used has dealer and service center. Because any controversial issues, especially warranty issues, are easier to resolve at your place of residence.

Efficiency 220V

Sellers of any product solve one problem - this is sales. Therefore, you can often hear that induction heating devices in 220 V have higher efficiency, than heating elements.

This is not true. Any energy does not disappear anywhere - this is what the law of physics says. Therefore, the efficiency of all electric boilers without exception is 100%. That is, for consumable 1 kW of electricity will be worked out 1 kW of thermal energy.

There are doubts that scale, which forms on the metal surfaces of the heating elements, can somehow affect the efficiency. These doubts are unnecessary, because scale is a deposit of calcium, which is an excellent conductor of current and heat. Of course, the thickness of the layer can affect during heating time, but this does not affect the efficiency.

For information, we will add that heat loss from gas, solid or liquid fuel boilers occurs because a significant portion of it flies out into the chimney. Induction electric boilers do not have a chimney, therefore all the heat is transferred to the coolant.

Economy

Based on the facts and calculations of the previous section, we can conclude that induction water heaters from TEN They do not differ in terms of energy efficiency.

The heat they generate does not evaporate anywhere, but remains in the room. And although it is believed that there are side costs of electricity, for example, heating of the copper spiral, this process still affects the heating of the coolant.

Compared to other types of heating equipment, the efficiency is higher. But here we have to compare not only the efficiency, but also the prices of energy carriers. And in this regard Gas models are superior to all.

Photo 2. Induction water heater installed on a tiled wall. It is highly efficient and keeps the room warm.

Performance characteristics

All electric heating boilers belong to the category silent. But, as practice shows, noise can still appear if:

- the boiler overheated for some reason;

- it is connected to a smaller diameter pipeline, than required by thermal engineering standards;

- due to vibration of the circulation pump.

All electric boilers are small in size and weight. Induction models weigh more than heating elements with the same technical characteristics. Therefore, it is recommended to use reinforced fasteners.

How to regulate temperature correctly?

So, it was found out that induction boilers used for heating networks, are not energy intensive. And in this indicator they are no different from their heating element analogues. But you can still save on electricity consumption if correctly regulate the temperature of the coolant.

And the principle of saving is as follows - it is necessary to heat the premises fully only when there are people in them. The rest of the time the temperature regime should be lowered (no more than +16 °C). It is difficult to do this manually, but automation solves these problems well.

Photo 3. Automatic temperature sensor with display, installed on the wall in the room. Switches off if the set mode is exceeded.

Usually they use it for this purpose in two ways:

- install temperature sensors (thermostats) on the walls of the rooms;

- use thermostats, which are mounted in the heating system, namely on radiators.

The first option is better because ideally it is necessary to control the air temperature, not the coolant temperature. But Both devices work on the same principle: turn on the power to the electric heater, in this case the induction coil, if the temperature has dropped below the set value. And, conversely, turn off the power when the temperature has exceeded the value set on the device.

Advantages and disadvantages of electric water heaters

All induction electric boilers have a number of advantages and disadvantages.

Durability

There are several reasons for long-term operation of boilers:

- complete absence of any moving or rotating parts;

- a coil of copper wire has a huge margin of safety, the winding turns are not located close to each other, but at a distance, so that even a breakdown of the insulation will not cause the boiler to stop;

- the rod will gradually deteriorate under the action of constant cycles heating-cooling and under the negative influence of salts inside the coolant, but this process is greatly extended in time, so it will last for several decades;

- the weak point is the transistors in the control unit, but today manufacturers equip the latter with modern high-quality parts, which, if the boilers are used correctly, will last for several decades.

Other advantages

The advantages include: small size of units, so there is no need to allocate a large area on the floor or wall for them. In essence, an induction boiler is a short pipe. They have simpler design in comparison with heating element models, therefore induction ones are more expensive cheaper.

Attention! For induction heating boilers, the quality of the water used does not play a big role. In this regard, boilers on heating elements react strongly to this parameter, because scale, deposited in large layers on the surfaces of heating elements, makes heat transfer difficult.

Flaws

As for the shortcomings, it should be noted here two main ones and one questionable one.

- Induction boiler is a powerful source of electromagnetic radiation. The latter creates interference for the operation of devices that receive ether and radio waves.

For example, cell phones, Wi-Fi modems, radiotelephones, and others.

- The electromagnetic field is in close contact with the coolant. Therefore, when the latter is heated to high temperatures, a slight boiling of water may occur. And this is the formation of air locks. The way out of this situation is to install air vents.

- Some experts believe that the water will carry an electromagnetic field throughout its entire passage through the heating network, which will negatively affect people's well-being. A dubious warning.

Types of induction boilers

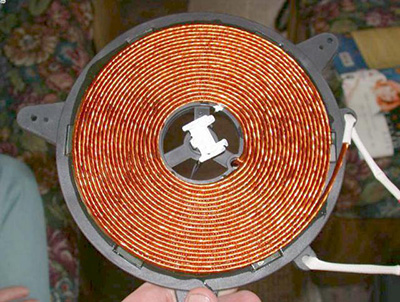

The above-described principle of operation of heating equipment is used in models with SAV marking. These are conventional induction boilers. Manufacturers offer a second type, which is called vortex and is labeled as VIN.

The latter is characterized by the material from which the device body is made. It is ferromagnetic.

The electromagnetic field affects both the rod inside the induction boiler and the body, which is washed from the inside by the coolant. Both parts are heated, which results in more intense and rapid heating of the water.

The VIN and SAV models differ in the way they are used metal in the production of the body. Due to this, the weight of the device increases significantly. But due to more intensive heating of the coolant, the dimensions of the boiler can be reduced. Hence, more favorable installation conditions.

Useful video

The video presents a comparative analysis of an induction electric boiler and a heating element boiler.

Homemade devices

The simplicity of the design and the general availability of the elements make it possible to make an induction boiler with your own hands. This is what modern Kulibins use. But let's approach the manufacture of the device from the position its safe operation.

This can be achieved only in factory conditions, where high-quality materials are used, welding is performed at the required parameters using consumables that comply with the standards of the technological process.

In factory conditions induction boiler is subject to laboratory control, where welded joints, the strength of bolted connections, other fasteners and planes are checked. Each device is required to be issued quality certificate, as confirmation of the warranties issued by the manufacturer.

It is this document that must be requested for presentation when the task of choosing arises. It is clear that homemade units do not have such a document, and therefore, no one gives guarantees for themThis is the huge disadvantage of homemade designs.