Providing constant heating to your home: an overview of all types of electric boilers, their design and operating principle

Heating a country house with an electric heating boiler is inferior to traditional gas and solid fuel boilers in terms of efficiency, but is a simple and effective way of heating.

Electric boiler - a tank with a heating element inside, and the circulation of the coolant through the pipes is carried out using a pump or by means of thermal convection.

According to their design, they can be heating element, electrode, induction. Such a boiler, operating from single-phase or three-phase current, controlled by a special controller, which helps maintain the optimum temperature or turn on the heating on a timer. Connecting an electric boiler to the heating network is easy to do yourself.

How do induction electric boilers work?

The principle of operation of the device is based on the phenomenon electromagnetic induction. The magnetic field generated by the coil induces an eddy current in the metal core, causing it to heat up.

The composition of such an electric boiler includes:

- coil;

- heat exchanger around the core;

- coolant inlet and outlet pipes;

- control unit;

- thyristor starters, power regulation;

- protective casing with a heat-insulating layer.

The coolant enters through the valve into the coil, which is located close to the core, where the liquid is heated. The efficiency reaches 99%, and the maximum power of individual devices exceeds 50 kW.

Advantages of induction heating

- High efficiency works;

- reliability and durability induction boiler;

- small dimensions;

- use of any liquid as a heat carrier (antifreeze, oil);

- safety of use with minimal maintenance of the device.

Flaws

- High price;

- complexity of connecting electrical wiring and piping.

Reference! Boiler manufacturers recommend using a special demineralized water or antifreeze with additives that prevent scale formation.

Heating element devices

TEN stands for thermal electric heater. Any heating element is a tube in the form letters U made of stainless steel or copper, inside which a nichrome or tungsten spiral is laid, and ceramics or quartz sand serves as a heat insulator. Single-contact heating elements have a straight tube, and the role of the second contact is performed by the body itself.

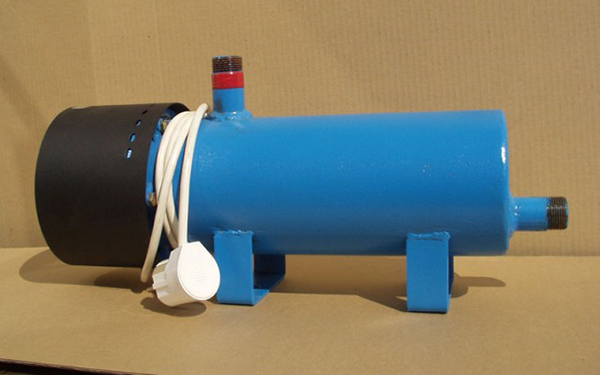

Photo 1. Floor-standing electric heating element boiler, painted blue, made of stainless steel.

An electric current passing through a tungsten filament heats it to a very high temperature. This heat absorbs quartz sand and gives it to the coolant. The operating principle is similar to an electric kettle.

Important! The surface of the heating elements heats up to very high temperatures, so they must be covered with water to cool.

Heating elements are placed inside the boiler with liquid. The number of heating elements determines boiler plant capacity.

Water heating occurs intensively, therefore circulation pumps are used in large heating circuits.

It's enough for a compact system convection heat exchange.

The thermostat, temperature and pressure sensor, and electric boiler control unit are responsible for temperature regulation. The expansion tank protects the heating system from airing.

Advantages

- Very easy to connect and maintain;

- low cost of electric boilers and heating elements (from 500 rubles per piece);

- rapid heating of liquid.

Flaws

Disadvantages Rod heating elements have significantly more:

- low efficiency due to the inefficient way of converting energy;

- scale formation on the heating elements and its entry into the heating circuit;

- minimum automation in cheap models requires manual control;

- The tungsten filament burns out over time, which leads to replacement of the heating element;

- there is a possibility of damage to the heating element casing and electric shock;

- high starting currents and load on electrical networks during operation;

- large dimensions of the electric boiler.

Power of individual heating elements does not exceed 5–6 kW. This is enough to heat a country house or to use as an emergency heating system.

Scale significantly reduces heating efficiency, so it is necessary to pay close attention to its control and water softening.

Methods to reduce water hardness for use in heating systems:

- Chemical method with the addition of sodium sulfate or soda ash. The solution is allowed to settle and the clean water is drained from the sediment. After filtering and boiling, the liquid is ready for use.

- Collection of rainwater with subsequent filtration.

- Using melted liquid.

- Buy distilled water at the store.

Electrode electric boilers

The principle of operation is based on the effect water conductivity due to the metal salts dissolved in it. The simplest boiler with two blades and all electrode heating devices operate on this principle.

Attention! You can only fill it with regular water tap water, distillate or desalted liquid will not heat up.

The electrode boiler device consists of a metal body covered with a protective layer, an electrode, outlet and inlet pipes. The phase wire is connected to the electrode, and the neutral wire to the body. Contact between the cathode and the anode is possible only through the coolant.

Photo 2. Electrode electric boiler with a metal body and protective layer, outlet and inlet pipes.

The electric current sets the ions contained in the liquid in motion. This chaotic movement heats the water. High heating intensity allows the use of compact devices with a small tank.

If the electrode boiler does not develop the required power, then the reason lies in low salinity water. You can correct the liquid by adding table salt.

Pros

- High thermal output;

- the most compact among other types of electric boilers;

- simple and reliable design;

- low power consumption.

Negative features

- Always operates at maximum power, will require the use of an automatic on-off system;

- dependence on the chemical composition of water;

- severe scale formation and salt precipitation;

- complex installation and connection scheme.

Features of electric boilers

The choice of electric water heating devices is huge among imported and Russian brands. Reasons for popularity electric boilers:

- easy to install and temperature control;

- low cost in comparison with other types of boilers;

- no dependence on gas and solid fuel;

- compactness and the possibility of wall mounting;

- an exhaust hood is not required in the room with the boiler;

- no open flame;

- silent operation;

- can be integrated into the heating system with the main gas boiler as a backup;

- no fuel storage required, there is no soot, ash or other combustion products;

- switching on at night or at preferential times is programmed;

- no emissions into the atmosphere Allows use in nature conservation areas.

Photo 3. Electric wall-mounted boiler, operates silently, suitable for small spaces.

The disadvantages of electric heating devices come from due to the high cost of electricity and low efficiency at high power. Therefore, heating a house with an area from 100 m2. economically inexpedient. Electric boilers show themselves best in the southern regions of the country with a competent combination of energy-saving properties of the house and the use of alternative energy sources.

Important! Frequent and prolonged power outages can become cause of defrosting the entire heating system in winter, unless a backup power source is provided.

Is it worth installing?

Before installing an electric boiler, you need to calculate heat loss of a house at maximum temperature difference.

If installing an electric boiler is impractical, it is used as an auxiliary heating device.

The installation helps to optimize the work:

- temperature sensor, protecting the system from overheating;

- load relay, which prevents the boiler from operating under heavy load on the electrical network;

- time relay (turns on the device at the most favorable hours, for example, at night).

Useful video

From the video you can learn how to properly connect an electric boiler and not make a mistake with the phases.

Conclusion

For any electric boiler, grounding is carried out, and the wiring is used according to GOST requirements for powerful heating devices. Correct installation and connection are the key to successful and safe operation.