Small in size, easy to operate: a potbelly stove for a summer house

A potbelly stove is a heating device made from steel, cast iron, combination of steel and cast iron.

Such stoves are installed in summer houses, garages, construction trailers and other temporary residences. Potbelly stoves are also used to heat greenhouses.

Content

Schemes of a wood-burning stove for a summer residence

Iron stoves used in the country come in different sizes, shapes, design features of the firebox, with or without a blower.

According to the type of work and design they are divided into:

- for conventional (single-chamber);

- on the channel;

- long-term combustion of fuel.

Reference. Metal stoves are heated with firewood, wood chips, brown and hard coal, peat briquettes. Cardboard, sawdust, and dung are burned in them.

Coal burns slowly and produces high temperatures (1500 degrees and above) because of this, the air, walls, ceiling, and cutting become very hot. That's why in summer cottages Coal is rarely used. Most of them are burned in potbelly stoves firewood, bark and chipsLet's consider the options for potbelly stoves that a garage or summer house owner can make with his own hands.

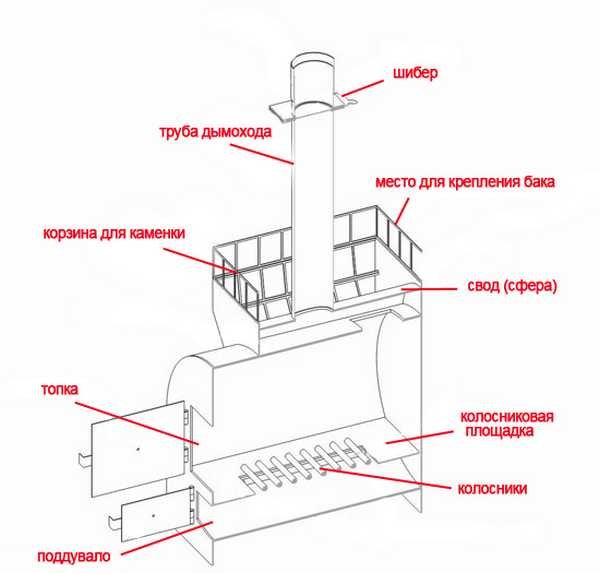

Single-chamber stoves consist of a solid metal body, which contains an ash pit (ash box), a grate, a combustion chamber, and an opening for a pipe (chimney). An example of such a stove is a cast-iron Soviet army stove, the simplest single-chamber iron stove for heating utility rooms.

Photo 1. Diagram of a single-chamber potbelly stove. The main parts of the device: firebox, ash pit, chimney.

The body of a factory-made potbelly stove has the shape of a rectangular parallelepiped with the following dimensions:

- height - 65.6 cm;

- length (depth) — 50.2 cm;

- width - 35.8 cm;

- height of racks (legs) — 19.4 cm;

- the height of the branch pipe intended for installation of the chimney - 6 cm;

- chimney diameter - 11 cm.

The stove weighs 36 kilograms, the heating power of a potbelly stove is 5 kW. The heater body is made of steel sheet with a thickness 6 mm. There is a solid steel door for loading fuel, and a pull-out drawer (ash pan) for removing ash. Firewood is used as fuel.

This small stove is designed to heat a room of up to 60-70 square meters. The flat top of the body is used as a hob. It has holes cut out for the burners, which are covered with rings of standard sizes.

Potbelly stove with a channel firebox has a more complex design. Steel plates are welded inside the firebox (from one to two), which form smoke channels. The channels slow down the movement of flue gases.

Reference. Factory-made heating and cooking iron stoves are channel-type in design.

Metal stoves-potbelly stoves of long burning have large dimensions. Air is supplied to the combustion chamber not only through the ash pit, but also through the side reducers.

In simplified versions, there is no ash pit, and holes are made in the door, the width of which is adjusted with a special valve.

The firebox is filled by two thirds. After the fuel has ignited, the air flow is reduced by closing the blower and opening the upper regulators.

The firewood slowly smolders in the top layer and gives off heat within a few hours.

Potbelly stoves from a gas cylinder

Gas cylinders have different volumes - from 10 to 50 liters. The larger the cylinder, the more spacious the firebox of the homemade stove.

Industrial enterprises usually do not manufacture stoves from used gas cylinders (such products, according to the accompanying instructions, are not subject to disassembly, they are simply supposed to be handed over for scrap). But Russian craftsmen have long mastered the production of compact stoves from gas cylinders that have served their time. The steel from which they are made, very durable, she withstands heat from burning any fuel. The body of the stove is made from one or two gas cylinders.

Scheme of a potbelly stove with a vertical fireboxThe heater has the following design features:

- The cylinder body has holes cut out for a pull-out ash pan, a branch pipe for the smoke pipe, and a firebox door;

- a removable grate is inserted above the ash chamber;

- the door is installed in an inclined pipe welded to the body;

- a non-removable hob is welded above the body;

- There are partitions inside the body so that combustion products are retained and heat the stove better.

Potbelly stove from a cylinder with a horizontal firebox consists of a body with a firebox door, an ash pit with a door, a branch pipe for the chimney, an additional hatch that serves as a burner. Thus, when constructing a potbelly stove Four holes are cut in the cylinder.

The ash pan is made of sheet steel with a thickness not less than 3 mm, the firebox door at the end of the cylinder is also cut out of thick steel and attached to hinges. If the craftsman has no experience in making doors and fastenings to them, you can buy Factory doors made of cast iron. The fastening is carried out with bolts to steel corners welded to the stove casing. The stands for the body are made of rods (construction reinforcement) or angle rolled metal.

How to make a device with your own hands

Before starting construction, choose a furnace design, determine the materials available and those that need to be purchased, and prepare the tool. In a summer house, place to install the heater. After the preliminary work, they begin manufacturing.

Selecting a project, drawings

Factors influencing the selection of a stove-potbelly stove design:

- region of residence;

- area and height of ceilings of a country house;

- tastes and preferences of the owner of the dacha.

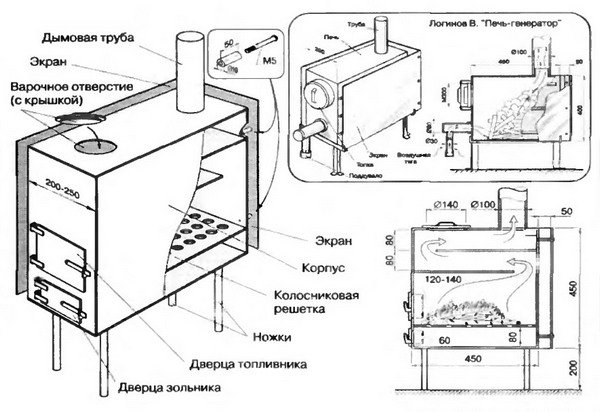

Photo 2. Drawing of a single-chamber potbelly stove, arrows show the parts of the stove. The device is additionally equipped with a hob.

In regions with low winter temperatures, potbelly stoves with a large firebox volume are chosen. In such areas, craftsmen also build long-burning iron stoves. If the winter temperature does not fall below minus 10-15 degrees, a small house can be heated with a small potbelly stove.

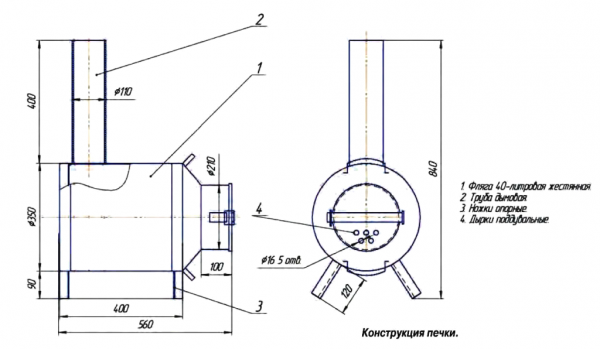

Photo 3. Drawing of a potbelly stove indicating the dimensions of the device and its components.

Craftsmen often produce neat, interesting iron stoves that become interior decorations. The potbelly stove is painted, polished, bluing is done on its surface, drawings and ornaments are applied.

In this example, a single-chamber homemade stove project is selected, the body of which is made from a propane gas cylinder. The stove is designed to heat a house with an area of 40 square meters.

Selection of materials

The materials for making a stove-potbelly stove from a cylinder are available and inexpensive. Most of them are reused. The list includes:

- old gas cylinder;

- sheet (roofing) steel thickness 3 mm or more;

- steel reinforcement (rod) diameter 8-10 mm;

- angle rolled products;

- cast iron oven door;

- cast iron blower door;

- steel pipe (diameter 110 mm).

The stove doors are often cut out of the cylinder body.

Special equipment is required for the work. — an arc welding machine and electrodes, a plasma cutter, a grinder and a set of discs for cutting steel, a gas wrench for unscrewing the valve. To mark the contours of parts and holes, you need a ruler, a metal pencil, chalk, a square, and a tape measure.

Preparing the installation site

It is not recommended to place a potbelly stove directly on a wooden floor. Heating of the floorboards from the hot body and coals falling out of the firebox create a fire hazard. Under the stove lay non-combustible material: sheets of flat slate, ceramic tiles, bonded with heat-resistant glue.

The most reliable foundation for a stove is a single-layer brickwork. Bricks are laid on mortar, leaving no gaps. The wall where the stove is located is protected by a brick screen, a sheet of flat slate, or natural stone tiles.

Step-by-step instructions for making

Before starting work, prepare all necessary materials, equipment, and tools. Construction plan:

- From a gas cylinder Using a key, unscrew the valve.

- To expel the remaining gas, fill the cylinder to the brim fill with water and let stand for several hours.

- The water is drained.

- Holes are marked on the cylinder body for the firebox, ash pan, chimney, burner.

- On a steel sheet cut out the ash pan parts.

- All parts are cut out with a grinder.

- The ash box is being welded.

- In the gaps of the pallet constructing a grate: a thick steel wire is welded to the edge of the hole, and several reinforcement rods are welded to it, parallel to each other.

- Welding the ash box directly to the body.

- Into the tray weld a frame from steel corners and attach the blower door to it with bolts.

- At the end of the cylinder weld pieces of sheet steelso that they form a portal for the firebox door.

- A frame made of steel corners is welded into the portal.

- They insert it into the resulting opening. the factory firebox door and fasten it with bolts to the corners.

- To the bottom of the stove weld the legs from steel angle or reinforcement.

- The chimney pipe itself is welded to the markings for the place for the chimney, and a short pipe of a height is welded into the hole located nearby. 5-6 cm with diameter 11-16 cmThis will be the burner.

- It is cut out of a sheet of steel a round cover for the burner, and a steel strip is welded along the length of its circumference (for a tighter closure).

- Potbelly stove cleanse from frozen metal splashes, scale, are being polished And paint heat-resistant paint.

Possible difficulties during construction

The valve of the gas cylinder is screwed on very tightly. It is not easy to remove. A good adjustable wrench And a lot of physical effort. To speed up the process, it is recommended to secure the cylinder.

Attention! You cannot start cutting the cylinder without first filling it with water, because residual propane may cause an explosion.

Cutting metal, cutting sheet steel with a grinder is a labor-intensive process. The work will be accelerated plasma cutter, which can be rented from specialized companies.

The finished stove-potbelly stove, placed on the base, may wobble. This happens if the heater legs are of different lengths. Align them with a grinder.

Useful video

Watch an interesting video that tells how to make a potbelly stove for a garage from a gas cylinder.

The benefits of using a potbelly stove

Can easy to melt in any weather and time of year.

Easy to clean. Ash is removed from the ash pit and from the floor of the stove with a scoop. The smoke pipes are easily disassembled. They are cleaned from condensate with a homemade brush.

Most stoves are home-made have little weight And are installed without a foundation. If necessary, the potbelly stove can be easily moved to a new location.

Comments