The most important part of the heating system: recommendations for choosing a gas double-circuit wall-mounted boiler

In the cold season, to create a comfortable temperature in residential buildings and industrial premises, they use heating systems.

Their operation is based on the movement of the coolant along a closed circuit from the boiler to the batteries.

If in addition to heating the serviced premises it is necessary to organize their hot water supply, the boiler design provides for a second circuit.

The price of gas fuel is significantly lower than the cost of electricity, therefore Most consumers prefer a gas boiler when arranging a heating system. A double-circuit wall-mounted gas boiler is a compact heating unit, convenient for placement. Its operation is based on the generation of thermal energy when burning gas fuel.

Main types of wall-mounted double-circuit boilers

By operating principle:

- convection;

- condensation.

By design features:

- with separate and bithermic heat exchanger;

- with open and closed combustion chamber.

Convection

The operating principle of a convection boiler is not complicated:

- Thermal energy is generated by a gas burner.

- The resulting heat is collected by a heat exchanger.

- In the hot water supply circuit, water is heated, and the heating circuit provides heating to the serviced premises.

In these processes up to ten percent of thermal energy is lost when exhaust gases are removed through the chimney.

Reference! Working fluids inside the boiler do not mix, the coolant and water circulate in independent circuits.

Condensing

Condensing boilers use a much more efficient method of operation, in which almost all generated heat is used in the network due to the additional collection of energy generated during the condensation of hot water vapor in the secondary heat exchanger.

Photo 1. Wall-mounted gas boiler with 2 circuits from the manufacturer Vaillant EcoTec, capable of saving gas fuel.

The heat released during this process is transferred back to the network, condensate is removed through the drainage system. Long-term use of such equipment provides significant savings in gas fuel, since the efficiency of such a device approaches to ninety-five percent.

With separate heat exchanger

The design of double-circuit gas boilers with a separate heat exchanger uses two heat exchangers. Primary, representing a coil with metal plates located between its turns, is included in the pipeline network of the heating system.

The second one is smaller in size and of a plate type., is used to provide consumers with hot water. It has two contoursHot water circulates through one of them, and the working fluid of the heating system circulates through the other.

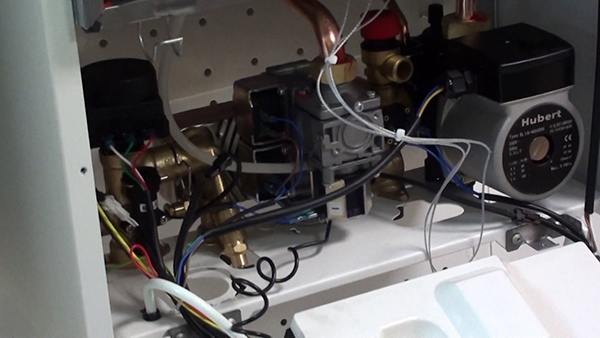

Photo 2. The gas wall-mounted double-circuit boiler from the manufacturer Hubert is equipped with two separate heat exchangers.

When operating boiler equipment with a separate heat exchanger in hot water supply mode the movement of the working fluid stops in the heating system and vice versa.

Attention! There is no significant decrease in temperature in heated rooms when hot water is supplied, since the time of use of water intake points is relatively short.

The constant circulation of the working fluid through the circuits ensures less scale formation in heat exchangers. The disadvantages include large sizes and quite high cost.

With bithermic heat exchanger

In the design of boilers with a bithermic heat exchanger along the internal channel of the heat exchanger water is moving, along the outer contour – coolantWhen the device is operating for heating, the movement of water stops, it heats up and vice versa.

Important! When using water intake points in boilers with such a heat exchanger design caution should be exercisedIt is necessary to wait until the hottest part of the water has drained, otherwise you may get burned.

Wall-mounted gas boilers with a bithermic heat exchanger have compact dimensions And low price. Their disadvantage is that as a result of stagnation of working fluids with high temperatures, the heat exchanger quickly becomes covered with scale. The cost of its repair is comparable to the price of a new heat exchanger.

With open and closed combustion chamber

In models with open combustion chambers, the air necessary to maintain the combustion process is supplied by gravity from the surrounding space.

For the device to work properly, you need ensure good supply ventilation and removal of exhaust gases through a chimney with natural draft.

Low noise level and simple design are the advantages of boilers with an open combustion chamber.

Gas boilers with closed combustion chambers have fans, with the help of which, through a specially equipped double-layer chimney exhaust gases are removed and air for the combustion chamber is taken from outside the house. The advantage of this equipment is Possibility of installation in any roomThe disadvantages include high power consumption, noisy operation and complex design.

Advantages of 2-circuit gas devices

- The compact dimensions of this type of equipment allow it to be used in apartments of multi-storey buildings.

There is no need to arrange a separate room for installation; the device fits perfectly into the interior of a small-sized home.

- When using a double-circuit gas boiler no need to pay for heating and hot water. This allows you to save significantly on monthly utility bills.

- The affordable cost of this type of boiler allows you to purchase it without much damage. for the family budget, while one device provides the serviced premises with hot water supply and autonomous heating.

Flaws

There are also negative aspects to the operation of this type of equipment.

- The devices have significantly less power compared to floor-standing gas boilers. and are not suitable for servicing large areas.

- When all water supply points are used simultaneously, the temperature in heated rooms decreases.

Useful video

A video that shows the operation diagram and principle of a double-circuit gas boiler.

Conclusion

The undoubted advantage of wall-mounted double-circuit gas boilers is ease of use and the possibility of using not only in country private houses, but also in ordinary apartments. They fit perfectly into the environment, without taking up much useful space. Functioning of boiler equipment fully automated and does not require human intervention in the operational process.

Comments