Review of household gas burners for heating. Rules for safe operation

Gas burners or nozzles are devices that intended for the preparation and combustion of gaseous fuel, maintaining the combustion temperature at the required level.

They are installed on different types of equipment: heating boilers, water heaters, heat generators and other.

The devices vary in power - models are produced for industrial needs and domestic use. All of them easy and safe to operate, are characterized by high efficiency and are cost-effective.

Propane Cylinder Nozzle: What is it?

Gas burners do not simply function as a nozzle into which gaseous fuel is supplied, but mix gas and oxygen from the air, providing a stable fuel composition for sustainable combustion.

The gas-air mixture is fed to the outlet pipes, where ignites from a spark from a piezoelectric element or electricity.

For maximum convenience, reliability and safety Many devices are equipped with special devices that automate the work.

Burners form an open flame, the safety of the heating boiler, gas consumption, and the range of adjustments depend on them. According to the principle of air injection into the fuel flow, devices for autonomous systems are divided into two groups: atmospheric and turbocharged (blown).

Important! The heating burners are working on natural gas (mainline) and liquefied gas, which is supplied in special cylinders. The use of this fuel is cost-effective and safe, especially for autonomous systems.

Types of domestic gas burners used indoors

Gas burners come in several types and are used with different types of boilers.

Atmospheric

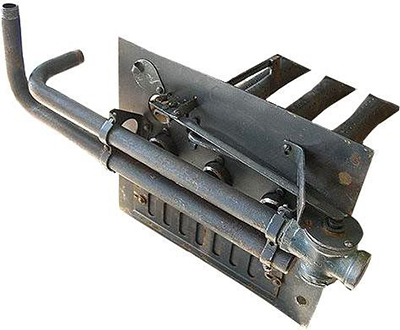

Nozzles of this type are used in floor-standing and wall-mounted boilers with open combustion chambers. They work similarly to a stovetop burner.: gas is mixed with air from the surrounding space without artificial injection. Visually, they are a set of hollow horizontal tubes with holes at the top.

Gas is supplied through the injector, air is drawn into the flow due to the pressure difference, a fuel mixture is formed, which is ignited by a spark. Combustion occurs through the upper openings. The torches are distributed over the allocated area, due to which ensures uniform combustion.

Photo 1. Atmospheric gas burner with hollow horizontal tubes and holes, suitable for wall-mounted and floor-standing boilers.

Advantages:

- energy independence;

- simplicity of design;

- maintainability;

- low noise level;

- affordable price.

With the help of an atmospheric burner, it is possible to convert a solid fuel boiler to gaseous fuel. For this purpose, the nozzle is mounted into the ash chamber.

Main flaw atmospheric devices - low powerIt is impossible to mix a large volume of air into the gas flow using natural draft, therefore powerful devices are only blower-type.

Reference! Maximum power of atmospheric burners - up to 9 kW. This is enough to heat a room of an area 90 m2.

Turbocharged blowers

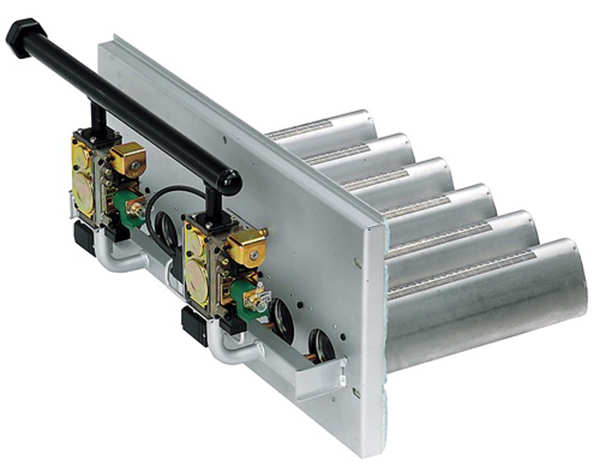

The devices are used in boilers with a closed combustion chamber, the design provides for special fan for forced air supply in the required volume. The main technological difference from atmospheric injectors is that the air-fuel mixture is formed not at the inlet, but at the outlet in the combustion area. And here precise regulation of air supply is also provided.

The burners are produced in a block design, installed on single- and double-circuit boilers, equipped with automatic control systems.

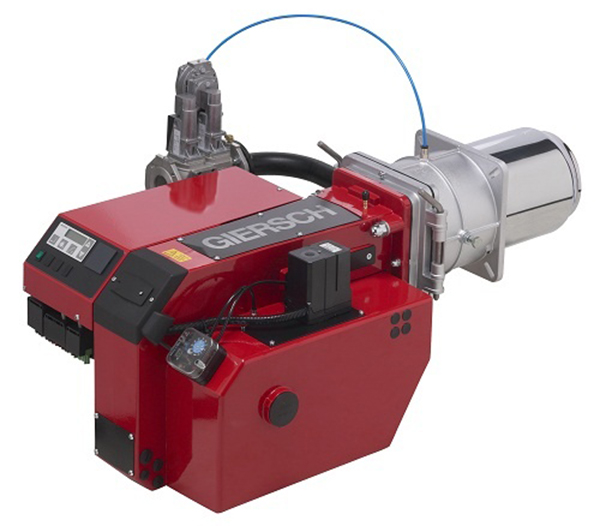

Photo 2. Giersch blast gas burner for boilers with automatic control and a closed combustion chamber.

The turbocharged units are equipped with the following auxiliary devices:

- gas and air filters for additional cleaning;

- relay that regulates the fan speed;

- gas flow regulators (consumption, starting pressure);

- reducers that stabilize gas pressure;

- Automatic devices that turn on/off the fan and gas flow in case of interruptions.

Due to forced air injection, turbocharged burners win in the following positions:

- combustion with high efficiency (not less than 90%);

- no power limitations;

- environmentally friendly combustion;

- constancy of coolant temperature due to flame modulation;

- gas saving — programming the boiler to decrease or increase the temperature at specified time intervals;

- management and security — automation reduces user involvement to a minimum.

Many models of turbocharged burners are divided into sections, which ensures complete combustion of gas, fast and uniform heating of heat exchangers, and does not form soot.

Flaws: high price, noise and dependence on electricity, which is why they are equipped with uninterruptible power supplies.

For stoves

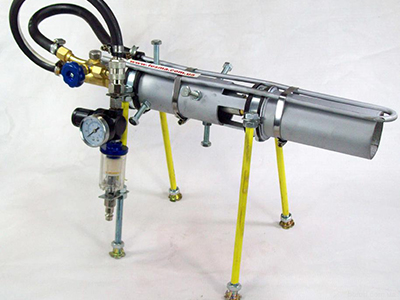

The design difference of furnace nozzles is the use of a larger number of distribution tubes and torch diffusers for uniform heating of the heating device body. When choosing, it is important to consider Features of furnace equipment:

- Atmospheric furnaces are used in brick kilns. burners, since inflatable ones require a sealed firebox.

- When installing atmospheric nozzles in a bathhouse or house ensure sufficient air flow, monitor the condition of the chimney.

- If the stove runs not only on gas, but also on other types of fuel, a turbocharged one will do. nozzle.

- Atmospheric heaters are installed in any type of furnace, regardless of the material.

In case of interruptions and pressure surges in the gas main, the safest option for heating will be a turbocharged nozzle with an automatic control function.

Photo 3. Gas atmospheric nozzle, equipped with torch diffusers, suitable for furnaces of any type.

For the garage

Gas boilers or stoves are prohibited to be installed in the premises where the car is parked and fuels and lubricants are stored. Such equipment requires separate boiler room and permission from the relevant authorities.

Since there is no need to heat the garage constantly, the following are used to warm up the room: portable heaters, convectors and heat guns, operating on cylinder fuel. The principle of their operation is simple: gas burns in the nozzle, and the fan distributes heat. For the garage, both atmospheric and fan-powered low-power devices are used.

Factory burners are equipped with reliable automation that switches off the heat generator at overheating, flame extinguishing, fuel exhaustion, CO levels exceeded2. Despite the fact that such devices provide smokeless, almost complete combustion of fuel, for safety in the garage, high-quality ventilation is carried out.

Selection criteria

The best option is to purchase a heating boiler already equipped with injectors, since the manufacturer supplies these devices that correspond to the equipment parameters. To choose the right unit, take into account five main parameters.

Heating boiler power

To calculate the boiler power, multiply it by its efficiency, for example, for installation 30 kW with 90% efficiency need a burner with power 33.3 kW.

Adjustment type

- Single-stage burners operate in two modes: on - off. The automatic system turns on the nozzle when the temperature in the system drops.

- Two-stage devices additionally have an intermediate low power mode.

- Modulating burners are fully automated and economical. Smooth power regulation 10–100% is carried out by microprocessor automation.

Fuel type

Burners can be designed for methane (natural gas), butane-propane (liquefied) or be universal.

Diameter

The main gas and the gas cylinders have different pressures when supplied, and they also require different volumes of air for air-fuel mixture. Therefore, for liquefied gas the diameter of the nozzles is smaller.

Manufacturers

The Germans products of brands Giersch Intercal, Buderus Logatop — high degree of automation and assembly accuracy.

Burners Weishaupt can operate at very low pressure Italian manufacturers FBR GAS, Ferroli Sun, Ecoflam, Lamborghini offer more affordable units that are not inferior in functionality.

Korean and Japanese Rinnai injectors technological efficiency is combined with a wealth of choice and a wide range of prices. The main advantage Russian devices (KONORD plant, Teplodar) - undemanding to gas quality.

Attention! In gas boilers, the burner recommended by the manufacturer in the operating instructions is used, since the design of water heaters is developed taking into account the type of nozzle.

Useful video

This video will show you how to reduce fuel consumption when using a gas burner.

Proper use is the key to home safety

Gas-air mixture explosive. Most often, a fire with an explosion occurs when the boiler is stopped and not completely closed burners. Therefore, before starting, you need to ventilate the furnace, blow out the gas pipeline if it is not under pressure.

Regularly check the operation of shut-off valves, control automation, do not neglect service inspection. To avoid explosions and fire hazards, it is better entrust the selection, installation and commissioning of injectors to specialists.

Portable devices with a gas burner are not used in houses without ventilation or with strong drafts.

Do not leave burners unattended or install them near flammable objects. In case of breakdowns, you don’t need to disassemble it yourself, but contact the service department. When using any gas appliances, follow the operating rules specified in the instructions.