High-tech equipment in the house: ways to connect a gas boiler

Gas - the most popular type of fuel in places where there is a centralized heating supply. It is a cheap and widespread source of energy.

But when installing a gas boiler it is necessary strictly observe safety precautions and act according to the instructions, following all requirements and rules.

Incorrect installation can result in additional refurbishment costs and, in the worst cases, to a leak or even an explosion.

Gas boiler connection diagrams

The scheme is different single-circuit and dual-circuit boilers.

Single-circuit

This device has one heat exchanger used to heat the coolant.

It is impossible to prepare water with it. for hot water supply (domestic needs). They are intended only for heating living quarters.

The units are divided into wall-mounted and floor-mounted according to the installation principle. The difference is in power.

The first ones have a limited one - 100 kW, for floor-standing ones there is practically no limit.

Wall mounted

- Attachment is made using special brackets.

Important! There must be a gap between the unit and the wall measuring from 30 to 50 cm.

- Checking the presence of draft in the outlet pipe of the unit is carried out before connecting it to the chimney. The diameter of the inlet opening must correspond to the diameter of the pipe at the chimney. The connections must be airtight.

- To prevent clogging of the heat exchanger, a filter is installed on the boiler pipe. water softening system.

- Before connecting to the heating system, it is necessary pressure testing of the unit.

- With the help of a flexible hose and paronite gaskets, it is done connection to the gas main.

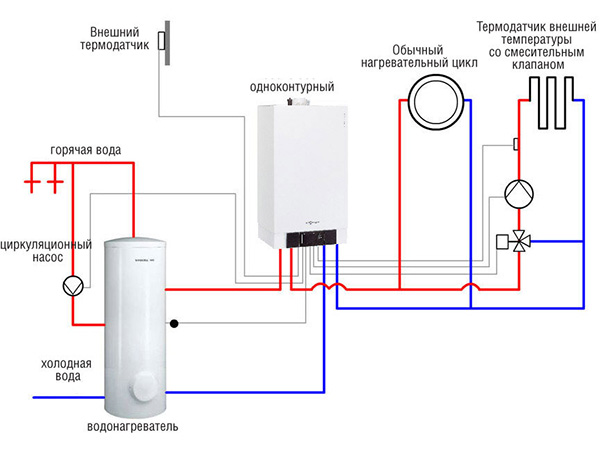

Photo 1. Connection diagram of a single-circuit wall-mounted boiler to a heating system with a circulation pump and a water heater.

Floor standing

- The device is installed on a specially designed prepared and cleared area.

- A hole is made for the chimney (if there is none) and the sizes of the diameters of both outlets (both the flue and the chimney) are checked to ensure that they match.

- A water softening filter is installed.

- The boiler is connected to heating system and gas main.

Attention! Due to the potential danger of the work, it is recommended to connect wall and floor units to the gas main. entrust to a specialist.

The tightness of the connections is important for both types of devices.

Double-circuit

Dual-circuit devices are distinguished by the presence 2 highways. The second line is designed to heat water for domestic needs, which allows refuse to use the boiler.

Wall mounted

The connection diagram for wall-mounted double-circuit boilers is not much different from single-circuit boilers. However, here connection of four (not two) pipes, a pair of which are used to heat water for household needs.

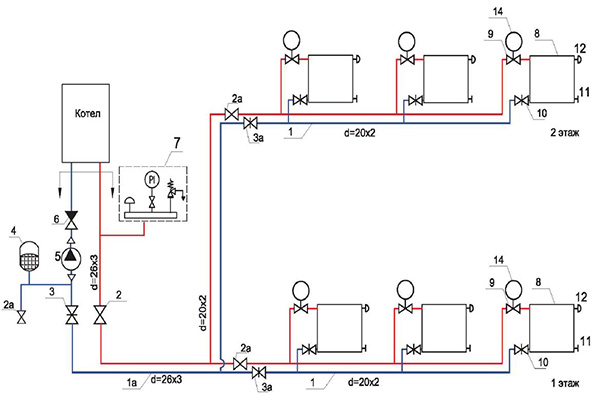

Photo 2. Connection diagram of a wall-mounted double-circuit boiler for a heating system for a private two-story house.

Floor standing

The connection of a floor-mounted dual-circuit type is similar to a single-circuit type, again taking into account the presence and connecting the second pair of pipes.

How to connect a gas boiler in a private house in order?

It is possible to install and correctly connect the device yourself, but this requires approval from gas services. During the work, thoughtful activity and the need for paperwork will be required: coordinating a number of issues and obtaining documents.

At first a contract is being drawn up with a natural gas supplier about its delivery to a private home. They are also involved in the project of gasification of the building and installation of the necessary equipment.

Before installation, all papers are checked (certificate, serial number of the product). If everything is in order, they proceed to installation.

The installation location is selected relatively type of device.

The floor-standing gas boiler is installed on a flat surface made of non-combustible materials. It is used, for example, tiles or concrete screed. And sometimes they put a sheet of galvanized steel with a protrusion on the front side up to 30 cm. Access to the structure must be unrestricted from any side.

Important! It is necessary that the boiler be located away from electrical appliances and fire sources, as well as not close to the wall.

The structure must have a uniform load on all supports.

The wall-mounted gas boiler is secured with brackets (included). Installation height — about 1 meter above the floor. First, the strips are fastened, then the unit is mounted on them.

Then the connection to the chimney takes place. Before this, it is checked presence of traction. To prevent leakage of toxic gases, connections are carefully sealed.

Photo 3. Wall-mounted gas boiler, installed more than a meter above the floor, connected to the chimney.

25 cm — the maximum length of the pipe section that connects the boiler to the chimney.

The next step is connection to the water supply. The first step is to install a filter for hard water purification, which prevents the heat exchanger from clogging. Taps and/or valves are installed on both sides of it.

To ensure optimum pressure in the system, the cut-in into the water supply is carried out either to the place where the pipe branches, or as close as possible to its entrance into the building. Usually, the water supply pipe is connected from the top of the unit, and the return pipe is connected from the bottom.

All communications must be equipped with a locking mechanism to enable immediately shut off the gas supply in case of danger.

Materials and tools

- Adjustable wrenches and dowels;

- building level to select the place for mounting the brackets, its length should not be less than 1 meter;

- hammer drill with a set of drills of different diameters for making holes in the wall for their fastening;

- brackets — they come in a set, but it’s better to have some in reserve;

- scissors, so that when cutting pipes, their protective layer responsible for tightness is not damaged;

- calibrator for flaring pipes;

- valves, taps — for fastening locking mechanisms;

- galvanized steel sheets and tools for cutting them.

Step-by-step connection of the heating circuit

Eat several ways to connect the circuit to the boiler, depending on the model and auxiliary equipment.

When connecting a single-circuit gas appliance to a heating system, the easiest way is use of shut-off valves and connecting the circuit with their help directly to the boiler.

The circulation of the coolant occurs in a natural mode, and a conventional expansion tank is installed in the system.

When connecting double-circuit devices, the work becomes more complicated, since a supply line is connected to the boiler. double set of pipes. The coolant flows directly through one, and hot water circulates through the second. The connection is also established using shut-off valves.

If the system is closed type, then the following should be installed: additional devices: circulation pump, membrane expansion tank and safety group.

Connection to the heating system

Location of connection nodes to the heating system (from the front side):

- left — supply of hot coolant to the circuit;

- on the right — return line.

When connecting the boiler, it is worth carefully checking the sealing and tightening of the nodes, but do not be too zealous due to the risk of damaging the threads and facing the problem of replacing all the connecting elements.

It is necessary to install and coarse filter to the return line, which will extend the life of the device by stopping solid particles.

Useful video

The video describes the basic rules for installing gas heating equipment.

How to check if the device is connected correctly?

To perform a performance test of the device, you must first check tightness of connections by crimping (2 atmospheres).

In addition, the following is required:

- evaluate the appearance of the boiler and the heating system (for cracks or other damage);

- check for draft in the chimney;

- check the coolant pressure;

- assess the state of the gas supply (low pressure in the network can stop the boiler on its own).

If you find problems with any of the elements of the device and the connection to the heating system, gas pipeline and water supply, you should contact specialists who can suggest a solution for a specific case.

First launch the boiler is carried out in the presence of representatives of gas services, who will check the quality of the work performed.