You can't do without qualified help! The intricacies of installing a wall-mounted gas boiler

In all cases, wherever it is planned to place a gas boiler, on the floor or on the wall, the installation is carried out accredited specialists from Gorgaz.

Gas supervision will allow installation, only if there is a certificate of conformity purchased equipment.

Content

Installation of a wall-mounted gas boiler. Materials and tools

Having chosen the model you like, ask how to attach it to the wall and what is offered in the kit for this to the boiler (hooks, power dowels). If the heater is sold without fasteners, they will have to be purchased additionally.

Refuse to purchase if the unit is manufactured not a very reputable manufacturer. Either this is a new supplier, or, more likely, one that doesn't particularly care about quality.

After paying for your purchase, you can take it home and start mounting it on the wall. For this you will need tools:

- electric drill or hammer drill;

- metal pipes;

- building level (laser is preferable).

The latter is used to check how level the unit is installed. This is especially important for condensing gas boilers. The slightest deviation from the vertical guarantees breakage, and in the near future.

Preparing the installation site

It should be remembered that the room where the gas boiler is installed is considered explosive and must meet a number of criteria established by law. Therefore, before placing an order, you should make sure that this is possible in your home, otherwise the purchase will be absolutely useless: Gorgaz will refuse to approve the procedure.

Usually a wall-mounted boiler is installed in the kitchen. Except ventilation and through hole on the front door (and it should always face the street), pay attention to the wall itself. Make sure it is strong and can withstand the installation of power fasteners, and even a boiler on it. To do this, reinforce the wall with wooden planksThe wall covering must be non-flammableIf there is a risk that it will catch fire during a fire, a layer of non-flammable material is placed on the wall, and then the boiler.

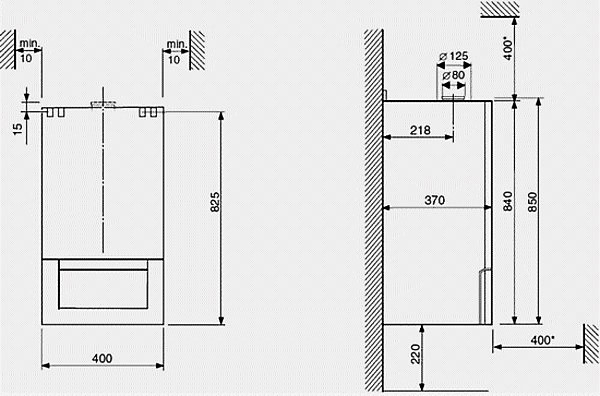

Photo 1. Approximate dimensions of a wall-mounted boiler and standards for its placement in relation to adjacent walls, floor and ceiling.

The unit, according to the standards, stands approximately 45 cm from the wallTherefore, it is necessary to attach it not directly to the panel, but to bars previously attached to the wall. Height from floor should be from 0.8 to 1.6 mThe remaining walls are covered with ceramic tiles for aesthetics.

Attention! When installing a condensing gas unit, it is important to remember that it hang with a tilt "away from you", that is, the distance between the wall and the boiler at the top is somewhat less than between the wall and the lower part of the unit.

Hanging the boiler

The installation procedure consists of the following steps:

- unpacking boiler;

- verification of markings on the body with the data in the certificate and invoices for the device;

- screwing the bracket or other suitable fasteners;

- Removing factory plugs from the unit;

- flushing internal pipes.

Now the boiler can be hung in the desired place. Check the horizontality boiler, adjust its position if necessary.

All that remains is to connect boiler to the system. If the technician has already arrived on call, you can involve him in the work.

Chimney in a private house

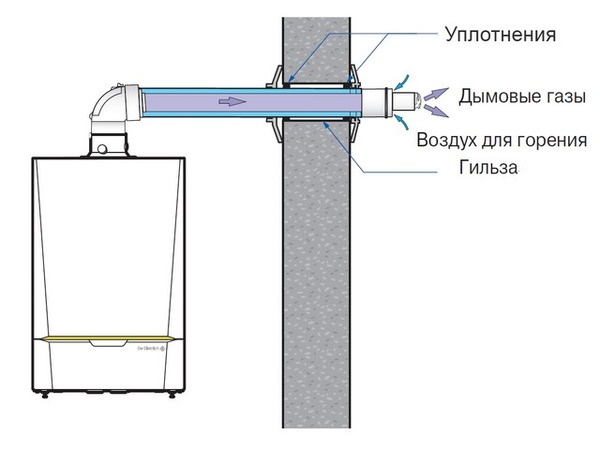

The most common thing found in houses is boilers. with closed firebox. This is understandable: they are easier to use, it is easier to connect them to the flue - you just need to screw them on coaxial pipeIn private houses, a coaxial flue is brought out out through the wall.

Photo 2. Diagram of the smoke exhaust from a gas boiler through the nearest wall. The movement of smoke gases and air is shown.

There are no strict requirements for the height of the pipe suspension, since draft is provided by the built-in fanAn open firebox requires the installation of an individual smoke exhaust system, and special attention must be paid to the cross-section of the pipe.

Attention! When buying a pipe, look at what it is made of. Only those that are suitable for work wear-resistant materials, which are not afraid of the vagaries of temperature and the effects of combustion products.

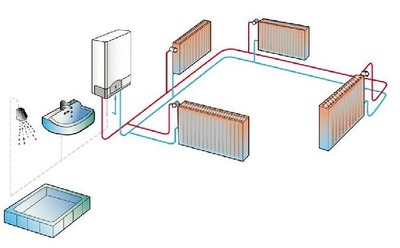

Connection to the heating system

What needs to be done is actually the same as when connecting the heatingThe difference lies in the taps and pipe diameters.

A filter is placed on the "cold" pipe, which will prevent dirt and metal particles from entering the heater.

Shut-off valves with detachable connections (so-called American ones). It is much easier and faster to work with them, and if the tap breaks down, it is easy to replace it with a new one.

Cold pressure pipes connect on the left, oriented from the center of the unit, the hot one - on the right side.

How to connect to a gas source

The gas line branch is connected with a flexible connection to the pipe on the heating unit. Shut-off valve must be equipped with a hermetically sealed filter. Sealing The threaded connection is carried out using paint and tow.

Do not use rubber hoses., they serve for a very short time. Usually the Gorgaz representative will stipulate this at the very beginning. The best option is corrugated stainless steel hose.

In the room where the wall-mounted heating device is installed, a gas sensor connected to a relay is requiredIf a leak occurs, the sensor gives a command to block the gas.

It will work at the same time sound alarm, notifying the owner about a breakdown.

Advice. This part of the work, as well as the first launch, is mandatory delegated to an accredited representative of Gorgaz with approval from a self-regulatory organization!

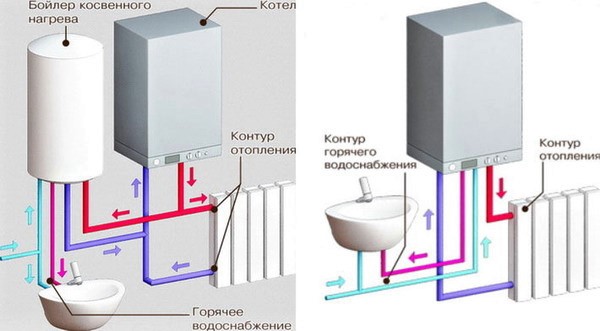

Double-circuit and single-circuit gas boilers

Differences in the operating principle These two units are as follows. Dual-circuit the heater will not only provide hot water from the tap, thanks to it all systems work as before, as if the hot water had not been turned off - This includes water supply, radiators, and even heated floors. The heat exchanger heats the water coming from the cold supply system.

Photo 3. Diagram showing the differences between single-circuit and dual-circuit wall-mounted boilers. The first requires a boiler.

Only dual circuit unit contains a three-way valve, which regulates the direction of the coolant flow. Heated water is directed towards the central heating. When the hot tap is opened, the sensor inside the unit switches the three-way valve to another position - water flows into the heat exchanger, where it heats the water.

Attention! While the hot tap is open, the so-called hot water priority, that is, the central heating is closed. Users often regard this nuance as an inconvenience.

So that you don’t have to wait for a hot stream (usually it appears half a minute or more after opening the tap), It is better to buy a flow-through boiler with a built-in boiler. However, this option is only suitable for apartments or small houses. For a large mansion or estate, it is unprofitable.

Single-circuit The boiler is only useful for heating cold water coming from the water supply.

Test run

Before starting the heating system for the first time slowly fill with water, up to the indicator pressure of 2 atm. After this, the tightness is checked. Any leaks found are eliminated.

About poor sealing best say soap bubblesTo do this, dilute a soap solution and apply it to the joints. Air bubbles will appear at the leaky joint.

Only by eliminating all the defects can we start the boiler again. This is done only in the presence of a Gorgaz employee.

Useful video

The video demonstrates the first stage of self-installation of a wall-mounted gas boiler.

Why are installation and connection errors dangerous?

Installation and maintenance of gas units are carried out exclusively by accredited employees of gas services, with permission from self-regulatory organizations. The boiler owner is unable to connect the boiler in most cases.

Mistakes are inevitable on the part of a newbie., due to which the boiler at best simply will not work. At worst, gas leaks are possible and one day it will be enough to simply flick the switch for an explosion to occur. The same threatens the gradual accumulation of combustion products and impurities in an incorrectly installed flue.