What is the best gas boiler heat exchanger cleaner? Recommendations for use

For safe operation of a gas boiler, it must be grounded in accordance with certain conditions.

Only registered devices are allowed to operate, after specialists from the gas service drew up an acceptance certificate.

A gas boiler does not belong to the category of electrical appliances, but in the process of performing its functions, the unit accumulates static electricity inside the metal frame, which is part of the design.

Over time accumulated static can cause problems, related to the control of equipment, for the proper operation of which the electronic board is responsible.

Why is it necessary to flush gas boilers?

To understand the importance of grounding a boiler, you just need to look at its structure diagram.

The device is attached to the wall or installed on the floor, both options do not contribute to electrical conductivity. The pipes are typically made of non-conducting propylene.

It becomes clear that static electricity has no other outlet than a radiator, in which water is concentrated.

As a result, being an excellent heat transfer, water also becomes an electrical conductor. When winter comes, the temperature of the equipment increases and the liquid is unable to conduct currentAs a result, the operation of the gas boiler becomes unsafe.

How to clean heat exchangers: chemicals

The procedure for washing the device should be carried out if any problems occur in the system operation.

Most owners of gas units seek help from specialists, but you can clean the boiler yourself.

Flushing of the gas appliance is carried out:

- For preventive purposes. The treatment period is twice a year, the expenditure of effort and auxiliary means is minimal.

- For contamination caused by scale or soot. In such a situation, you can cope either on your own or seek help from specialists.

- In case of a malfunction of the heat generator or a complete stop in the operation of the boiler. If such a situation occurs, you cannot do without the intervention of experts. The master eliminates all problems and flushes the heat exchanger.

There are various means that can be used to clean gas equipment.

The most popular of them are the following.

Citric acid

Citric acid can be purchased at almost any grocery store. It is recommended to make from this product solution with a concentration of 0.5% to 1.5%, depending on the complexity of the contamination.

Liquid heated to temperature 60 °C, easily cope with scale and oxidation without damaging the metal coating of the equipment.

Citric acid is the best way to clean devices made of stainless steel, copper and brass. In application of the substance safely for health.

Photo 1. Citric acid package, 15 g, manufacturer "Five Cooks". Cleans copper, brass and stainless steel devices well.

Orthophosphoric

This type of chemical compound is widely used in agriculture and its acquisition is not difficult. Orthophosphoric acid Suitable for cleaning heat exchangers of any type.

To carry out boiler cleaning, the following is done: 13% solution. This concentration will help to effectively remove all types of dirt and scale, and will also create a certain protective layer on the metal surface. The acid is safe for health in use.

Salt

Due to the fact that hydrochloric acid recognized as a precursor in the territory of the Russian Federation (an auxiliary substance in the production of narcotic drugs), measures to distribute it have been tightened and are regulated by the relevant authorities.

However, despite this fact, you can buy a solution of hydrochloric acid in a pharmacy, which sold under the name gastric juice.

In the process of cleaning the elements of the heat exchanger of gas equipment, consisting of made of copper and stainless steel, are actively used 2-5% solution hydrochloric acid. It contains special components - inhibitors, which help protect the metal and effectively dissolve all kinds of carbonates and oxidation products.

Attention! It is worth noting that HCl is dangerous and an aggressive reagent, therefore, when working with it at home, care and concentration are required.

Sulfamic

To buy sulfamic acid, simply enter its name in the search bar of your Internet browser. Organizations and enterprises related to the chemical industry will offer a wide range of substances at various prices.

The ability of this reagent to dissolve scale and dirt completely depends on the chemical composition the last ones.

Accordingly, before carrying out the cleaning procedure, it is recommended to study the structure of the existing scale and dirt.

According to experts, the optimal temperature for working with sulfamic acid is 55—65 °C, and the recommended concentration of the solution is 2-3%. Due to the low concentration for household use the product does not pose a danger to humans.

Specialized liquids

Not only chemical acids are used to clean gas appliances. There are effective means for this purpose.

Detex

In addition to chemical acid solutions, a specialized product called Detex is also used to flush gas appliances.

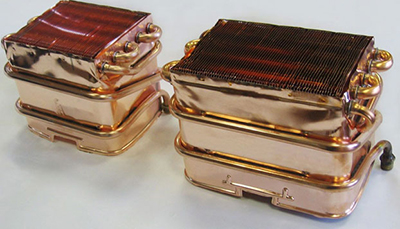

Photo 2. Three canisters of different volumes of Detex heat exchanger cleaner. Removes deposits from cast iron, steel and copper devices.

It helps effectively in work with cast iron, copper and steel heat exchangers, actively removes scale, oxidation products, salt and biological deposits.

Reference! The Detex product contains: many surfactants (surfactants) and inhibitor compounds that help protect the metal from negative damaging factors, which, in turn, extends lifespan gas units.

The concentrated Detex substance is mixed with water to obtain 10-17% solution. During the active action of the product, gas may be released in the heat exchanger. The end of gas-emission processes indicates that the cleaning procedure is complete.

In case an additional run of the cleaning agent is required, the concentration of the reagent is increasedAt the end of the flushing procedure, it is important to treat the heat exchanger with a neutralizing liquid and distilled water.

GEL Boiler Cleaner DE

Boiler Cleaner DE is a concentrated liquid containing inorganic acids and inhibitors, which help to get rid of rust.

This reagent will perfectly cope with limescale and other contaminants in parts made of copper and steel. For other metals and alloys, use is prohibited due to corrosion.

Boiler Cleaner DE is diluted in water until 10-30% solutionDuring the cleaning process, the product is periodically added to the solution to maintain the concentration. At the final stage, it is recommended to additional rinsing with Boiler Cleaner N and then with water.

Attention! Boiler Cleaner DE is a strong acidic product and should be used with caution when working with it. rubber gloves and safety glasses must be usedIn case of contact with skin, it should be treated with a solution of Boiler Cleaner N or sodium bicarbonate.

Useful video

The video shows what is better for dealing with scale on a heat exchanger: citric and acetic acid or electrolyte.

Safety precautions

Proper operation of gas equipment, in particular cleaning the heat exchanger, is an important component of successful boiler operation, extends its life and reduces monetary costs.

When washing the device, you should not forget about safety precautions and safety precautions, for this you need to follow these guidelines:

- when working with acids use protective clothing and rubber gloves;

- do not raise permissible concentration of solutions;

- do not use substances with expired shelf life;

- observe storage temperature conditions reagents;

- provide inaccessibility of reagents for children.

Comments