Extremely efficient in heating - gas boilers with an open combustion chamber

With the combustion chamber open natural draft is used.

This means that the air required for the operation of the gas boiler comes from the room in which the equipment is located. Combustion products and exhaust gases are removed through the chimney. gas boiler.

The device of a gas boiler with an open combustion chamber

The operation of such a gas boiler uses natural draft. This means that air comes from the environment into the combustion chamber. without the use of automatic devicesThe flue gases are also discharged outside under their own power.

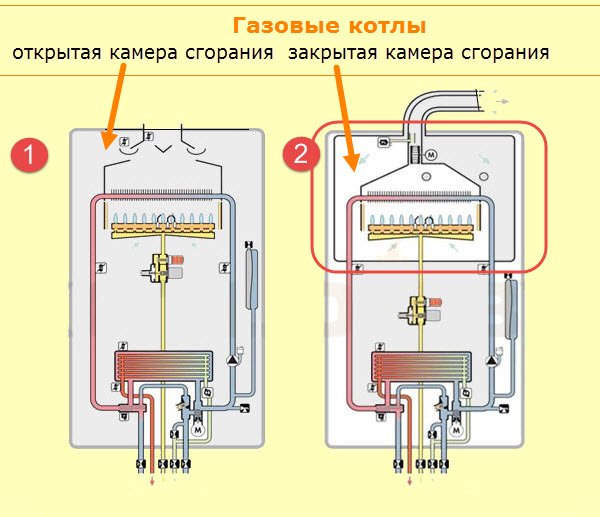

Photo 1. Comparison of the design of a gas boiler with an open (left) and closed (right) combustion chamber.

Gas boiler consists of the following elements:

- gas burner;

- heat exchanger;

- circulation pump (optional);

- automatic sensors, valves, programmers (not always present);

- housings.

The burner is located under the heat exchanger pipes. It is made steel or copper. First option more durable and long lasting, second is characterized by high efficiency. The flame heats the water, which is supplied to the heating radiators by the pump. Sometimes the water moves without a pump, under its own power. Then the house warms up more slowly, but the heating is more economical.

Automation controls the work gas boiler. It switches off if the gas supply is interrupted, it is often possible to set the desired temperature mode. But There is also simpler equipment, without automatic adjustment. It can work without electricity.

The body covers the system from all sides. Gas is supplied from below, and there is a gas outlet at the top. hole for connecting the chimney. The heated gases are discharged to the street due to the fact that their density is higher than that of the cold outside air. This difference creates the necessary draft.

Attention! In addition to the chimney, the room where such equipment is installed must have forced ventilation system. It helps create a draft. If it is not enough, the room will be stuffy. In addition, there is a risk of carbon monoxide poisoning.

By type of accommodation gas boilers are divided into floor and wall. They differ in size and power (the first ones are larger and more powerful). Perhaps connection to a single-circuit or dual-circuit system heating. The dual-circuit system provides not only heating but also hot water for domestic use.

Photo 2. Wall-mounted gas boiler with an open combustion chamber. The chimney is located at the top.

Advantages of such boilers

The popularity of natural draft gas boilers is due to their advantages. low noise level and low cost both the equipment itself and subsequent repairs.

Price

Since the design is simpler, the price is lower.. This often becomes the deciding factor.

Silence

Open chamber boilers not equipped with water movement pumps, work almost silently. The loudest sound they make is roar of flameTherefore, it is comfortable to be in houses with such heating both during the day and at night.

Cheap repairs

The reason is the same as for the low cost: simplicity of design. In particular, there is no fan-heater, which rarely lasts more than a few years.

Disadvantages of the devices

Due to the need for constant draft, drafts arise. In addition, its strength depends on weather conditions (temperature, wind). And the work of the hood in the kitchen also affects the draft. There are other disadvantages.

Expensive installation

Open chamber boilers dangerous to install in residential areas.

It is advisable to arrange for them separate boiler room, the dimensions of which depend on the power of the device. The furnace is thought out at the stage of designing the house.

In it there must be windows. A reliable system for forced ventilation of the room will also be required. This significantly increases the overall installation costs.

Important! Wall-mounted gas boiler models are allowed to be installed in the kitchen, if its volume more than 7.5 m3, and the ceilings above 2 meters. A window of area is required not less than 0.6 m2.

Sometimes to increase reliability to gas boilers add sensors, which monitor undesirable phenomena that interfere with operation (for example, weakening of draft). If necessary, the boiler is automatically switched off. Such a system also requires additional costs.

The presence of a vertical chimney

A vertical chimney is necessary to remove exhaust gases. Certain requirements are imposed on it:

- The cross-section of the pipe is not less than the diameter of the branch pipe to remove smoke.

- Height to first turn - not less than 0.5 meters And two pipe diameters.

- Definite height of the pipe above the roof.

Photo 3. Wall-mounted gas boiler with an open combustion chamber. It is equipped with a chimney made of steel pipes.

It is determined by the location on the roof:

- no more than 1.5 meters from the ridge or on a flat roof - 0.5 m;

- from 1.5 to 3 meters to the ridge - not lower than its height;

- further than 3 meters from the ridge - not lower than the imaginary line drawn from the ridge at an angle of 10° to the horizon.

Attention! The material used is steel or special polymer materials. A brick chimney won't do. It will quickly collapse under the influence of condensate.

Arrangement of a suitable chimney to the gas boiler quite difficultIn addition, it is also associated with certain material costs.

Selecting a device

When choosing a specific model of a gas boiler, it is worth considering the following characteristics:

- power;

- method of arrangement;

- number of contours;

- Features of burners;

- built-in automation.

From power The amount of gas boiler heat depends on how much of the room it will be able to heat. If it is not enough, it will be too cold. And if it is overworked, not only will it be too hot, but the fuel costs will also increase.

To determine the required power, do heat calculation. This is a calculation of heat loss through the roof, walls, windows and doors, etc. They largely depend on the materials used and the quality of insulation. And the power is approximately determined by the following formula: for heating 10 m2 premises with ceiling heights of about 2.5 m enough 1 kW.

Low power models gas boilers are produced wall-mounted. They take up less space and do not require a separate room. Such boilers are suitable for an apartment or a small cottage.

Floor models gas boilers are located in separate fireboxes. The sizes depend on the power of the equipment. They are suitable for large country houses, including for permanent residence.

Photo 4. Floor-standing gas boiler with an open combustion chamber. The device is connected to the water heating circuit.

Burners differ in flame adjustment. They are divided into:

- single-stage;

- two-stage;

- and multi-stage.

The first type of gas burners has two possible positions: on/off. The second one is added half power operation. In multi-stage the range is wider: 10—100% from productivity. The more control options, the more economical the heating. But the cost of the boiler itself increases.

Automation includes not only the adjustment of gas burners, but also monitoring the draft and temperature of the coolant. It reduces fuel consumption, but increases the cost of equipment and the likelihood of breakdown.

Important! Automatic operation requires electricity. If there are frequent interruptions with it, it is better to opt for simpler models that do not need it.

Useful video

Watch the video to learn how to choose the right gas boiler.

Rules for safe use

Natural draft gas boilers are quite popular due to their low price and other advantages. But when using gas boilers We must not forget about safety rules:

- The firebox must comply with the standards.

- The use of flammable materials is prohibited. near a heating device, store flammable liquids, etc. nearby.

- For energy-dependent equipment it is mandatory grounding and UPS.

- It connects directly from the control panel.

- Do not open while working. or violate the integrity of the body.

- Clean only after switching off and from stable surfaces.

- Avoid overloading.

- If smoke, gas or burning smell appears disconnect from the power grid and gas pipeline. Then ventilate the room and call a specialist.

- Regularly check the chimney, the tightness of the pipes, and the water level in the system.

- Once or twice a year carry out diagnostics with the help of a specialist.

Comments