What do you need to know about floor-standing gas boilers for heating a private home?

Single-circuit floor-standing Gas boilers are used for heating private houses and industrial buildings.

These units have proven themselves well not only in the conditions of the middle zone, but also in Siberia and the North.

They are reliable in operation and serve several decades.

Content

- Types of floor-standing gas boilers for heating a private house

- Device

- Key technical characteristics

- Requirements for the premises

- Installation requirements

- Recommendations for choosing a single-circuit boiler

- Features of operation

- Pros and cons

- Useful video

- Signs of malfunctions and what to do if they are detected

Types of floor-standing gas boilers for heating a private house

Gas floor boilers are produced in two modifications:

-

Single-circuit They are intended exclusively for heating and do not have a system for collecting water for household needs.

They differ in the method of fuel ignition. Gas is ignited using piezo ignition systems or electric ignition.

- Double-circuit — used for heating and heating sanitary and domestic water.

Combustion chamber types:

- Open: air comes from the technical room where the heater is located.

- Closed: the air flow comes "from the street". The burners in such chambers are completely isolated from the air environment of the house and do not burn oxygen.

Reference! Combustion products are removed from open combustion chambers only by natural draft. From closed ones, flue gases are removed forcibly, with the help of smoke exhaust fan.

Burner types:

- Atmospheric — simple in design, use room air for combustion.

- Supercharged (fan, replaceable) - installed in closed-type chambers. They ensure rapid combustion of the gas-air mixture, significantly increasing the boiler efficiency.

Types of heat exchangers for floor heaters:

- Cast iron: expensive, but durable, serve more than 30 yearsCast iron almost never burns out and is not subject to corrosion.

- Steel — service life 15-20 years.

Energy-independent models of heating devices

Among single-circuit heaters there are many energy-independent models. Autonomous — do not require electricity: such a boiler has a built-in piezo ignition system.

They have open combustion chambers and atmospheric burners.

For autonomous circulation, the pipes through which the cooling coolant returns are mounted at an angle to the heater. This is necessary so that the water can move freely into the boiler heat exchanger.

Device

Device gas single-circuit boilers depends on the complexity of the model. The basic diagram of the unit includes:

- frame;

- control and monitoring unit;

- combustion chamber;

- burners;

- heat exchanger.

The control and monitoring unit is designed to set operating modes.

Modern models have self-diagnosis system, which allows you to detect technical problems. Messages about breakdowns and failures are displayed on the screen.

Boilers with electrical appliances (circulation pump, smoke exhaust fan, fan burner) have a protection system that stops the gas supply when the electricity is turned off. Modern models have temperature sensors, a freeze protection system, and an energy-saving mode.

Operating principle

Gas is supplied from the main network to the burners through a pipeline. Piezo device (or electric ignition system) ignites the fuel in the burner. The air and gas mixture is burned in the combustion chamber and heats the heat exchanger.

It gets hot in it coolant, which circulates through the heating system. The water gives off heat and returns to the boiler, where it is heated again in the heat exchanger. When burning, flue gases are formed, which are removed through the chimney.

Key technical characteristics

The quality of heating of the house in winter depends on the technical features of the heater. The key characteristics include:

- boiler capacity;

- Unit efficiency;

- gas consumption;

- temperature parameters heating the coolant.

High-power boilers quickly heat the liquid circulating in extended heating systems. This allows heating large areas and multi-story buildings.

Efficiency of floor standing boilers 79-98%. If the model is equipped with a condensate collection system, the efficiency increases up to 105-116%.

Gas consumption depends on the burner design, its type, and operating mode parameters. This indicator varies among different models and can be found in the heater manual.

The temperature parameters of heating the coolant are approximately the same for all models. Heat exchangers heat water (antifreeze) up to 87-90 °C.

Requirements for the premises

Gas single-circuit floor boilers are installed in brick, panel (stone) and wooden houses. To install a heater with a capacity up to 150 kW choose a separate room on any floor, basement, cellar, attic, extension. For boilers with an open combustion chamber, the ratio of the heater power and the room volume is as follows:

- power less than 30 kW — the volume of the room from 7.5 m³;

- 30-60 kW — from 13.5 m³;

- more than 60 kW - from 15 m³.

The premises are selected in accordance with the following requirements:

- height from floor to ceiling - 2.5 m;

- the walls are made of fireproof materials that can withstand open fire 45 minutes;

- availability natural light;

- the presence of a transom window, a transom (glazing area - 30 cm² per cubic meter of volume);

- width of the entrance door - not less than 0.8 m (the door must open outward);

- durable, level floor made of non-combustible material.

For boilers with a closed combustion chamber, the volume of the technical room is not important. But the presence of a window or transom of the appropriate parameters is mandatory.

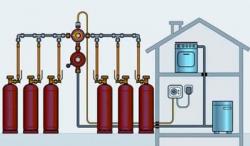

Installation requirements

All gas services offer services for complete installation, assembly, connection and start-up of the boiler. Homeowners prepare the premises according to instructions from gas service specialistsSuch works include:

- preparation premises;

- construction chimney;

- preliminary boiler installation;

- installation heating system.

After installation, the boiler is leveled. horizontally and vertically. They make the piping (system of equipment and pipes for supplying the coolant) according to the instructions.

After that they invite gas service specialist, who will complete the installation work, connect the gas and carry out a test run.

Recommendations for choosing a single-circuit boiler

The following factors influence the choice of device: power, autonomy, design features (burner type, heat exchanger material). An important characteristic is fuel consumption.

Attention! It is not recommended to choose a boiler with a large power reserve, this will lead to an increase heating costs, rapid wear of the heat exchanger and breakdowns.

Experts recommend adding to the estimated power no more than 25%.

For the owner of the house, the convenience and reliability of automation are important. The more perfect the control, monitoring, and self-diagnostic systems, the fewer emergency situations are created.

Photo 1. Floor-standing single-circuit steel gas boiler, model AOGV-11, manufacturer - "ZhMZ", Russia.

After calculating the required power, you can start choosing a boiler. Single-circuit floor heaters from manufacturers are available for sale Germany, Slovenia, France, Italy, South Korea and China.

I'm leading in the ratingst brands Bosch, Vaillant, Baxi, Protherm, Ariston, Biasi, NAVIEN, ElectroluxRussian boilers are distinguished by their reliability; in case of breakdown of such a heater, it is easier to find replacement parts.

Features of operation

Adult family members can independently start and turn off the boiler, change the burner operating modes and other parameters provided by the instructions. With sufficient experience, the boiler owner performs simple maintenance.

- monitors the condition burners and cleans the device when a thick layer of soot forms;

- cleans chimney before the heating season (or as needed);

- washes heating system before the start of seasonal operation;

- visually evaluates gas pressure: if the heating of the coolant is slow, call a technician.

Incorrect actions lead to breakdowns and situations dangerous to human life. When using, do not:

- restrict air circulation in the technical room;

- move the boiler, connected to the gas pipeline;

- operate the device if the display shows warning sign, but the problem is not resolved;

- open gas valve;

- keep flammable materials and liquids in the technical room.

Pros and cons

Advantages:

- simplicity in operation;

- economy (the cost of purchasing gas is less than the cost of purchasing diesel fuel and paying for electricity);

- eco-friendliness boiler (a small amount of harmful substances is released into the atmosphere);

- the boiler takes up small area;

- automation In emergency situations, it blocks the gas supply.

Flaws:

- high fire hazard in case of emergency gas leak;

- high demands to buildings and premises in which the boiler is installed;

- the need to receive Gas service permit for installation;

- constant gas consumption in the pilot burner.

Useful video

Watch the video to learn how to choose the right gas boiler.

Signs of malfunctions and what to do if they are detected

Gas boiler malfunctions occur either immediately after startup or during operation. Signs of malfunctions include:

- smell of gas near the boiler, in a utility room or in the house;

- low temperature coolant at the outlet of the heat exchanger;

- can be heard inside the device crackling and noise;

- from the body water is dripping;

- boiler often switches off;

- weak flame on the burner;

- the chimney quickly becomes clogged soot.

If any faults are detected, call Gas service masters. If you smell gas, open the windows and ventilate the house. Do not turn on electrical appliances until the leak is fixed.