What is a gas boiler thermocouple and what is it for?

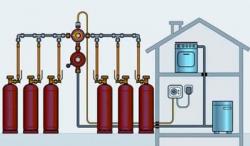

In many homes, the central element of the heating system is gas boiler. However, to maintain the device in good working order, it is necessary to take into account the operating features of the equipment.

For example, during the operation of a boiler plant inside the combustion chamber air temperature is increasing, so it is important control this parameter.

A thermocouple is used specifically for this purpose - a thermoelectric device, which is practically the only device for accurate measurement of elevated temperatures. Today, equipment is used that operates in conjunction with automatic valves.

Content

Features of temperature regulation in gas boilers with a thermocouple

The widespread use of the equipment is due to the fact that this device is considered the main way to measure air temperature, as well as control the flame level.

After all, the device is not exposed to high temperatures and operates on a special principle that allows it to obtain accurate readings and quickly respond even to minor changes.

What is it for?

A thermocouple is a device that is installed in heating equipment and is designed to convert thermal energy into electric current for electromagnetic coils and performs the function of the main component of gas control protection. The device works in combination with with a special gas shut-off valve, blocking the fuel flow.

Operating principle

The device is made using alloy of metalsIt can withstand high temperatures. However, if the equipment fails, the gas boiler will stop working.

Photo 1. Thermocouple for a gas boiler with automatic control 345-1000 mm, manufacturer - "Arbat", Russia.

After all, this thermoelement functions in conjunction with a special electromagnetic shut-off valve that regulates the flow of gas into the fuel tract, which closes immediately after the thermocouple breaks.

The operating principle of the device is based on the following physical phenomenon: two metals are joined and when heated at the attachment points (the working area that is placed in the flame) a flame appears on the cold ends voltageThis is called the Seebeck effect.

Attention! Many solenoid valve models are sensitive and therefore remain open until the input voltage is will not drop to 20 mV.

Technical specifications

The thermocouple has the following technical parameters:

- wide range temperatures;

- high precision measurements;

- increased resistance to corrosion;

- electronic control mechanism.

Varieties

The thermocouple is characterized by a simple structure. If you have the appropriate skills, you can even make this device yourself at home. However, it is better to buy an industrial device, having first studied technical specifications, as well as the features of all types of devices.

Specialized companies produce thermocouples three types:

- Type E — two plates are used for manufacturing: constantan and chromel. This device is characterized by increased productivity. In addition, it controls the process occurring in the temperature range from -5°C to 74°C.

- Type J — the device has an iron plate instead of chromel, which does not worsen the technical characteristics of the device. It has increased sensitivity to changes, and the temperature range is from -4°C to 74°C.

-

Type K — such thermocouples are the most popular. They are equipped with plates made of aluminum and chromel.

The operating range varies within from -20°C to 135°C, and the manufacturers managed to increase the sensitivity itself by several positions.

The service life of this device is determined by environment of use: thus, in carbon dioxide, the chromel plate becomes covered with rust in the form of green rot, the alloy quickly deteriorates and the device loses its non-magnetic properties.

There are other types of thermocouples, however, they are not suitable for use in gas boilers for the following reasons:

- alloys contain precious metals, so they have a high cost;

- such models are nothing no better than types K, E or J.

How to check if a device is working properly using a multimeter

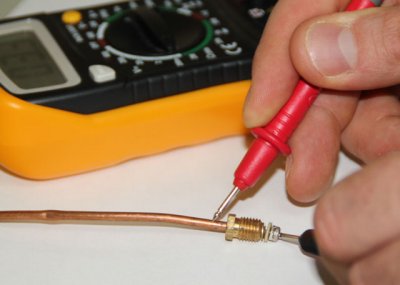

If there is a suspicion of a breakdown, then diagnostics of the thermostat's serviceability are performed. It is carried out in the following ways:

- One end of the device is connected to a multimeter, and the opposite one is heated with a gas burner or a lighter. If the device is working properly, the voltage below 50 mV.

- The condition needs to be checked carefully. conductors for contamination or oxidized areas. These also indicate a breakdown.

How to choose correctly

In order for the device to work properly and not cause the entire system to fail, it is necessary to carefully select the device. For this, the following features are taken into account:

- The technical parameters of the thermocouple must fully comply characteristics of the gas boiler.

- There should be no on the device visible damage (microcracks, chips, abrasions).

- Markings must be visible.

- Preference is given to products only verified companies, who are responsible for the quality of the products.

Replacement if you can't repair it yourself

The device causes failures for various reasons. You can replace the broken device with a new one on one's ownTo do this, you need to follow the step-by-step instructions:

- First, unscrew it with a key special nut, which the thermocouple is attached to the pipe.

- It unscrews compensating screw, which secures the device in place (it is located directly under the mounting bracket).

- Carefully is being removed old device.

- It is inserted into the vacated hole new device.

- Everything is recorded compensating screw, and then with a nut.

- In progress leak test. If necessary, a sealant is used - polymer or ceramic.

When carrying out the procedure, it should be remembered that an under-tightened or over-tightened threaded connection will be dangerous for the serviceability of the system.

Useful video

Check out this video to see how a thermocouple is constructed and works.

Is it possible to bend during repairs?

A thermocouple is one of the elements of a heating system that has a fairly simple design. All modern models of heating equipment, gas-powered. It is a sensor for measuring the air temperature inside the combustion chamber and also checking for the presence of a flame.

This ensures safe operation of the heating system.

When the pilot light goes out or the temperature is exceeded, the device immediately reacts by changing the voltage and also activates the shut-off valve.

However, for the thermocouple to function properly, it is necessary to perform the following steps: installation, strictly following the instructions. And also it is necessary to regularly check the serviceability of the device and in no case bend it, so as not to disturb the accuracy of the work.