Ecological and inexpensive! Choosing a gas boiler for heating a private house

It is necessary to approach the issues of connecting the heating of a residential premises responsibly, because we are talking about gas equipment. To the installation of devices certain requirements are imposed.

Therefore, you need to understand what activities are allowed to be carried out independently, and what should be entrusted to specialists.

Content

- Using a gas boiler to heat a wooden or stone private house

- Types of domestic boilers

- Efficiency comparison

- How to Properly Set Up a Natural Gas Heating Device

- Service Features

- Fines for violation of safety rules

- Possible problems and solutions

- Useful video

- In case of breakdown, contact a specialist

- Comments (3 opinions)

Using a gas boiler to heat a wooden or stone private house

In SNiP "Gas Supply" No. 2.04.08-87* (from 2002) The requirements for the installation of heating equipment are specified:

- for a heating device the kitchen volume should be larger 9 m3;

- for rooms with heaters, install a chimney with a height of not less than 2 m;

- the kitchen or room where the boilers are placed must be equipped with a ventilation duct;

- to allow air to flow into the adjacent room, arrange a grate or a gap with a larger cross-section 0.02 sq.m.

Reference. These requirements do not apply to residential buildings owned by citizens by right of personal ownership, if the basements of these buildings equipped with natural light, A The supply is carried out by means of natural gas.

Installation of gas appliances in residential buildings should take place in rooms with a height of not less than 2.2 m, which have a window with a transom, an exhaust hood, and a natural light source. The room's own volume should be no less than:

- 8 cubic meters — for gas stoves with two burners;

- 12 cubic meters - With three burners;

- 15 cubic meters - With four burners.

Important! If the specified requirements cannot be met, the installation of gas appliances in the premises may be permitted on a case-by-case basis upon obtaining consent. from local sanitary inspection authorities.

It is not allowed to install in the same room. more than two capacious water heaters or two small heating boilers.

Types of domestic boilers

Gas heating boilers are divided into several varieties, each of which has its own characteristics.

By the number of contours

Double-circuit boilers differ from single-circuit ones in that they heat water not only for central heating system, but also for hot water supply systems.

Photo 1. Connection diagram of a double-circuit gas boiler: in the middle is a hose for gas supply, at the edges are water circuits (for heating and hot water supply).

Of the dual-circuit installations, the market mainly offers boilers, since all solid fuel and liquid fuel devices are single-circuit. Therefore, the question of choosing a single- or dual-circuit device may arise only for those who plan to heat their home using gas.

Features of single-circuit boiler:

- It is cheaper compared to a double-circuit one, but additional heating of the DHW system is required purchase of a boiler;

- warms up in the boiler all the water, so the device can be used almost unlimitedly;

- the boiler allows establish circulation, thanks to which, when you open the tap, warm water immediately flows out of it;

- installation of a single-circuit boiler and a water heater — complex process due to the large number of additional elements in the system;

- you can buy cheaper a wall-mounted unit or a floor-standing model with a durable heat exchanger made of cast iron;

- over time the water is cooling down and requires heating.

Features of dual-circuit boiler:

- the device is worth it cheaper, than a kit that includes a single-circuit device;

- necessary little space;

- heats only the amount of water which is needed at the moment;

- a stream of hot water heated in a flow heater, limited;

- tap water temperature may vary depending on the jet pressure, for example, when opening the second tap;

- to activate the DHW system water heating mode, need a strong flow liquids;

- in systems with flow heaters it is impossible to start the circulation of hot water, therefore if the tap is far from the boiler, you will have to wait for hot water up to 10 seconds.

By placement method

Floor standing gas boiler — a classic device that has not undergone any major changes over the years. The heat exchanger is made made of steel or cast iron. Discussions about which material is better continue to this day. On the one hand, cast iron heat exchangers are less susceptible to corrosion, but on the other hand, they are fragile, which means the risk of microcracks during loading, unloading and transportation is quite high.

Important! When using hard water, the heat exchanger wears out over time. A steel boiler is much lighter than a cast iron one, but if the operating standards are violated corrosion may occur.

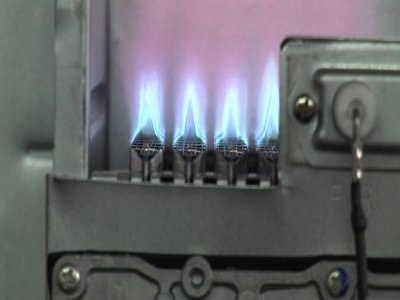

Floor standing gas boilers are distinguished with supercharged (replaceable fans)) And atmospheric burners. The first ones show a higher level of efficiency and are more expensive. The second ones are cheap and work much quieter.

Atmospheric burner — is a component of the boiler, i.e. it is included in its price. The forced-draft burner is not included in the kit and is sold separately.

The capacity of boilers with an atmospheric burner varies from 10 to 80 kW, while units with a replaceable forced-draft burner show a power of several thousand kW.

This will allow each buyer to choose the heating plan that suits them.

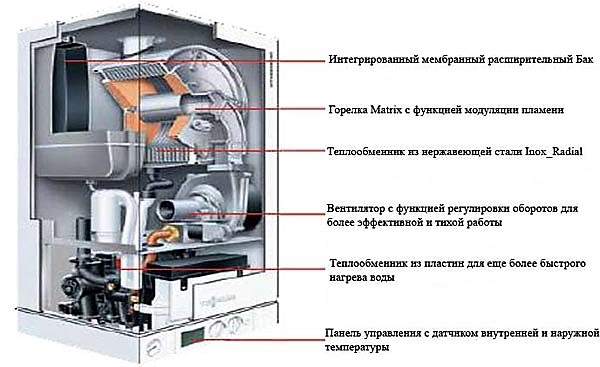

Wall mounted type of equipment appeared relatively recently, but has already managed to win many fans. A suspended gas boiler is called a mini-boiler room: in a small body there is not only a heat exchanger, a burner and a control device, but also circulation pumps, as well as a safety system, a tank, thermometers, pressure gauges and other components.

Another significant advantage - easy installation of devices. Compactness, the ability to easily fit a gas boiler into the layout of the room is another advantage of wall-mounted units.

Mainly wall-mounted boilers equipped with elements that ensure safety operation. Flame sensors turn off the fuel supply when fire hits them, block the thermostat, and stop the boiler in case of an emergency increase in temperature.

By type of energy use

Convection Gas boilers heat the coolant only by means of thermal energy released during gas combustion.

At the same time, a huge amount of heat is lost upwards with smoke fumes, and the water vapor present in them, in turn, does not provide additional heating of the heat carrier.

Advantages convection boilers:

- simplicity of design;

- ease of installation, removal and repair;

- low price;

- small dimensions.

Condensation a gas boiler is a device that uses not only the heat of gas combustion for heating, but also water vapor energy, found in flue gas.

Reference. The condenser system of the boiler operation will allow you to save from 20 to 25% of fuel, which will provide cheaper heating overall.

Efficiency comparison

When burning the same amount of gas, condensing boilers emit 25% more heat, than their counterparts. This effect is achieved by including a water economizer in the boiler system, on which the flue gas vapors settle. As a result, the smoke at the outlet has a temperature of below +40 °C.

Manufacturers of condensing units guarantee that the boiler efficiency can reach 110%. However, this is unrealistic. This is because the calculations do not take into account the entire volume of heat released, but only the energy of the combustible gas. The volume of steam and smoke depends on many factors.

Some countries are already using a new method of calculating efficiency that takes into account all the heat released from the combustion of fuel and steam.

Disadvantage of condensation boilers - high price (which quickly pays for itself) and dependence on electricity.

Photo 2. Diagram of a condensing gas heating boiler with the main parts of the device indicated.

How to Properly Set Up a Natural Gas Heating Device

Energy-dependent boilers require electricity and the availability of natural gas under pressure.

Step by step process:

- Move the control knob to the “ignition” position and press it. At this point, gas will start flowing into the burner. Then hold the handle down. Under the pressure of the piezo element button, the gas on the pilot lighter is ignited. Hold the control handle for a couple of seconds to warm up the thermocouple, it will supply the necessary voltage to the electronic valve, which will open the gas supply to the main burner.

- Release the handle and turn it counterclockwise to set the desired heating power value. Open the thermostat valve and press the feed valve through the lever. The gas will flow to the main burner, ignite the pilot light and begin to heat the coolant.

- Once the water has heated up to the required level, move the thermostatic valve, which, under the action of the thermostatic element, will close the gas supply valve and the main burner will go out.

- When the coolant cools to the specified level Move the lever and turn on the gas valve. The cycle starts again.

Service Features

Activities that you can do yourself:

- burner inspection: cleaning the retaining washer, ignition element electrode, flame sensor;

- purging of air sensors, by means of which the modes of creation of the gas-air mixture are regulated;

- flushing and, if necessary, replacing the filters that are in the gas section.

Measures performed by a specialist:

- Diagnostics of the fire segment in the combustion chamber: All boiler parts that are connected to the flare are cleaned.

- Maintenance of internal gas ducts: cleaning of gas ducts. In this case, the chimney is not put into operation - this refers to secondary measures.

- Diagnostics and repair of electrical mechanisms boiler.

- Setting up all nodes devices and burners.

- Analysis of the composition of the exhaust gases, which allows you to determine whether the burner is properly adjusted for operation, as well as the correctness and efficiency of combustion of a particular type of fuel.

Fines for violation of safety rules

The bill was passed January 27, 2015, provides for administrative liability for entities, officials and enterprises for failure to comply with technical safety regulations when using gas equipment.

If during the inspection facts of violation of the rules are discovered, the owner of the apartment will have to pay a fine from 1 to 2 thousand rubles, and to officials who are responsible for the proper functioning of the equipment - from 5 to 20 thousand, while specialized organizations are subject to fines from 40 to 100 thousand rublesIf violations are recorded again, the fine will double.

Possible problems and solutions

Like any device, gas boilers can break down. If the device has an electronic controller, then fix its malfunction Only a professional can do this, who has not only the relevant experience, but also the necessary equipment.

Common causes of breakdowns:

- The igniter does not turn on.

If the igniter does not work, the most likely cause is contamination of the insulator through which the wire passes through the housing into the combustion chamber. This type of failure is eliminated by wiping the insulator with a rag.

- The water is not heating up.

If the water in the DHW circuit does not heat up well, this indicates that there is too much scale and dirt on the walls of the heat exchanger. The problem is solved by manual cleaning.

- "Tacting the Boiler".

When choosing a high-power boiler, so-called boiler cycling may occur, when the gas boiler turns on too often due to overheating of the heat carrier.

Attention! Knowing how to set up a gas boiler in this case is extremely important. After all, when the boiler is "clocked", gas consumption increases, and too frequent start-up of the automation will lead to early wear.

To fix the problem, you can reduce the gas flow to the burner. Read the instructions carefully, find the gas valve and adjust the gas supply.

Useful video

Watch the video, which talks about the features of choosing a gas boiler for an apartment or house.

In case of breakdown, contact a specialist

Each user decides whether to repair the boiler themselves or seek help from a specialist. But since we are talking about quite serious equipment that requires certain knowledge, then contacting a specialist for help in repairing the equipment is considered the safest measure.

Comments