Why choose one thing when you can combine them? Combination boiler for wood and coal, and other types of fuel

Conventional boilers work on only one type of fuel. This is not always convenient, as each of them has both pros and cons.

And combined models use several options at once, combining their benefits.

Content

Advantages of combination boilers

Similar heating equipment popular due to its advantages. These include:

- independence from centralized highways;

- high efficiency;

- variety of options.

Autonomous heating

Not all country houses have the ability to connect to the centralized power supply and main gas pipeline. But even if there is a connection, there remains probability of an accident. In addition, use only for heating Electricity is expensive.

There are no such problems with solid and liquid fuels., since it is purchased as needed and stored directly on the site. Therefore, when combining heat sources for a boiler in the house, it will be comfortable in any situation.

Variety of designs

There are many options for boiler design. There are single-circuit and dual-circuit models. The first ones provide only heating, while the second ones also provide hot water.

Reference. Often possible connect even several circuits heating. Then the heating is distributed separately for different rooms. In this case, fewer pipes are used. Or both radiator heating and a water-heated floor system are connected.

Availability of different types of resources varies depending on the location. Therefore, boiler models with various combinations are produced. There are dual-fuel and multi-fuel (universal) options.

High efficiency

Such boilers have a high efficiency, reaching up to 85-90%.

It is achieved by:

- modern combustion technology;

- efficient coil design;

- ability to switch between different types of fuel.

Disadvantages of combination boilers

They are not without their drawbacks.

Large size and weight

The dimensions of such boilers are larger, especially if they are built-in. two fireboxes at once, so a large firebox will be needed.

Reference. Most models are - floor-standing. Only some of them, powered by electricity and gas, are hung on the wall.

Difficulty of installation

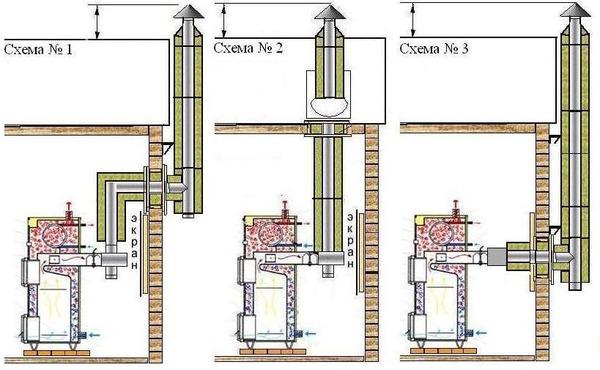

Even a traditional boiler can be installed not always easy. If firewood, coal or pellets are used, installation is mandatory. chimney.

Photo 1. Three options for the chimney arrangement for a boiler using solid fuel.

For gas heating will require connection to the gas pipeline, and for electric — to the electrical network.

Attention! If gas is used, you will have to get permission to install from the gas service.

High price

Since the boiler design is more complex, the cost is higher. But this is a disadvantage pays for itself with resource savings during operation.

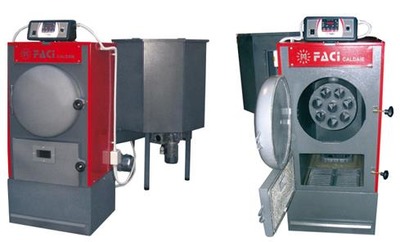

Boiler device

Overall he it is arranged in the same way as a regular one. But there are some specific features associated with the use of multiple resources.

Boiler included in the water heating system. Solid or liquid fuel burns, heating water in a heat exchanger. It moves through pipes to radiators, where it gives off heat. Then the cooled liquid returns to the heat exchanger.

Photo 2. Internal structure of a combination boiler: the possibility of heating with wood or gas is shown.

With electricity The heating principle is a little different. Heating element is used, which heats the water in the tank.

Reference. Switching between different heating methods occurs automatically or manually. In the latter case, the burner or the entire firebox is replaced. And in the first case, there are two fireboxes and/or a heating element.

What elements are included in the design and how do they interact?

The main parts of the boiler are:

- firebox;

- burner;

- heating element;

- heat exchanger;

- automation;

- frame;

- outlet pipe.

Sometimes there is one combustion chamber capable of providing combustion two types of raw materialsIn other cases, two are installed at once, for solid and liquid types.

Heat exchanger, as a rule, is done from pipes. Then, with the same volume, the surface area is larger, and the liquid heats up faster. It is located next to the firebox, usually at the top or bottom. And if there are two, the coil is located between them. The pipes for connecting the pipeline system are connected to the heat exchanger.

Automatic control significantly makes it easy to use boiler. The set temperature is maintained without human intervention. It is measured by sensors. If necessary, the damper opens more or less. This regulates the oxygen supply and combustion intensity. The heating power is also regulated by the heating element. If one of the raw materials is not available, the device will switch to another. The parameters are set on the control panel. Some models have remote control.

Frame the boiler is being manufactured made of steel or cast iron. It is made for thermal insulation double. More expensive models also have noise insulation.

Design Features

The specifics of the boiler design are associated with the use of various heat sources and depends on the types of fuel. The following options are possible:

- Two combustion chambers instead of one.

- Combination fireboxes and heating elements.

- Removable pellet hopper and automatic feed mechanism.

These features and lead to an increase in size boiler.

Fuel: wood, coal, gas and others

There are quite a few fuel options for the boiler:

- firewood;

- coal;

- pellets, fuel briquettes;

- gas (trunk and liquefied);

- diesel;

- worked out oil.

Useful video

The video discusses the advantages of a combination boiler with a heating element over a conventional one.

Basic rules for safe use

To ensure safety, it is essential:

- Edit correctly equipment.

- Provide sufficient ventilation rooms with a boiler.

- Pave separate cable and ensure protection against leaks and short circuits.

- Right design and lay a chimney.

- Near heated surfaces use only non-flammable materials.

- Use only high-quality materials and equipment.

Comments