All about the benefits of a diesel heating boiler: advantages and disadvantages

Diesel fuel (diesel oil) is a hydrocarbon product treated with alkali. It is obtained during direct oil distillation.

Diesel fuel is used as fuel for low-speed engines, electric generators and boilers. Boiling point solar oil 240–400 °C, viscosity 5-9 mm2/With.

Diesel fuel (DT) differs from diesel fuel in its technical characteristics, properties and area of application. DT is used in high-speed engines of diesel locomotives, sea and river vessels, and agricultural machinery. Boiling point DT: 180–360 °C, viscosity 2–4.5 mm2/WithAdditives are added to the product.

Heating boilers are supplied with instruction with a description of the requirements for fuel quality. Using low-quality diesel fuel or other types of hydrocarbon fuel will lead to breakdowns and rapid wear of the device parts.

Content

Advantages of using diesel boilers

Affordable cost is one of the main advantages of devices that run on diesel fuel. The price of devices for a private home is 30-100 thousand rubles. There are dozens of models of devices on sale.

The advantages also include:

- autonomy apparatus;

- safety of use;

- high efficiency;

- fuel availability.

Autonomy of the device

The device requires electricity to operate. If there is no connection to the network, the safety and control automation is powered by an electric generator, so the boiler is considered autonomous heater.

All boilers of this type have automatic regulation of operating modes. The water in the heat exchangers is heated to a set temperature, and the burner is switched on and off automatically.

Safety of use

Device not dangerous to operate. The automatic system stops fuel combustion if there is a power outage or short circuit in electrical appliances.

Diesel fuel is a relatively safe fuel (compared to natural gas or gasoline).

When used correctly explosion or fire of the device is excluded.

For installation of the boiler no permission from regulatory authorities is required. The homeowner only needs to comply with the requirements for the room in which the boiler is installed and for the chimney.

High efficiency

When diesel fuel burns, it releases a large amount of heat. Efficiency domestic diesel boilers are 75–92%.

Thanks to the heat-insulating layer under the body, almost all the heat is transferred to the heat exchangers and is spent on heating water. The efficiency of boilers of this type is not much less than that of gas boilers.

Availability of solar oil

Diesel fuel is usually sold at gas stations, it is poured into canisters or mobile container on a trailer.

Large quantities of diesel fuel are purchased from wholesale suppliers.

Terms of delivery or pick-up are negotiated separately.

Disadvantages of using boilers

These include:

- high cost heating with diesel fuel;

- strict requirements for fuel quality;

- unpleasant smell and noise;

- constant checks boiler.

High cost

The price of diesel fuel and solar oil is constantly changing, usually increasing.

At an average cost 38 rubles per liter buying a ton of fuel will cost in 38 thousand rubles, which, given a long heating season, will amount to a large sum.

Heating with diesel fuel more expensive than heating with liquefied gas, coal or firewood.

But these costs are less than the cost of heating with electrical appliances and an electric boiler.

Strict requirements for fuel quality

In case of low quality of diesel fuel, presence of foreign hydrocarbons, water, mechanical suspensions in the fuel the equipment deteriorates quickly. The burners emit soot, which clogs the nozzles, settles on the heat exchangers and the walls of the combustion chamber, and in the chimney.

As a result, the efficiency of the device is greatly reduced, and it is necessary to carry out unscheduled boiler cleanings with the involvement of a specialist. Therefore, it is better to purchase a large batch of high-quality fuel from a trusted supplier.

Unpleasant smell and noise

The smell of diesel fuel comes from the fuel tank. If the boiler room is poorly ventilated, it penetrates into the living rooms. Diesel fuel vapors create fire hazard.

To eliminate the smell in the technical room, they do supply and exhaust ventilation.

The noise from the burners can be quite loud. To reduce the hum of the fans and flames, use Burners with sound-absorbing casing or close the boiler room with a tight door.

Constant checks

The device must not be left unattended for a long time. The automatic system switches off the device in case of any malfunction. If this happens in winter, the water in the heating system will freeze quickly.

Heating equipment requires regular checks. A full inspection is done at the beginning and at the end of the heating season, for which a specialist is invited. Unscheduled checks are carried out in case of frequent spontaneous shutdown of burners and breakdowns.

Heating equipment device

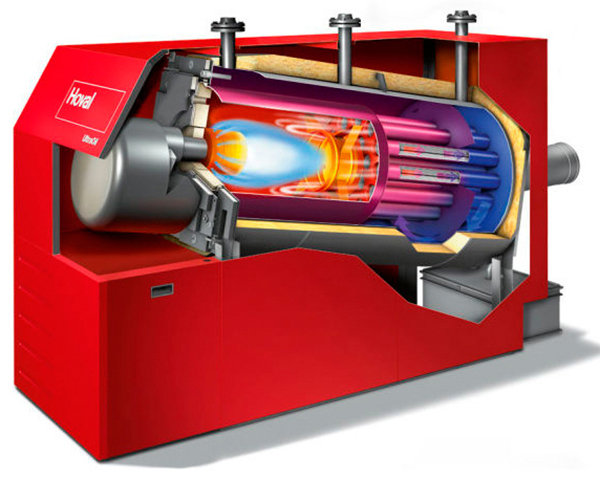

The operating principle is to heat the heat exchangers with hot flue gases generated during fuel combustion. The basic diagram includes next details and devices:

- steel or cast iron body with a layer of insulation;

- diesel burner;

- heat exchanger;

- combustion chamber;

- remote control;

- Parameter sensors works;

- chimney hole.

Photo 1. A heating boiler with a red steel body in section, equipped with a combustion chamber and a heat exchanger.

Device works like this: diesel fuel is supplied to the burner, the fuel is ignited by the ignition transformer. The fuel is burned in the combustion chamber. Hot gases heat the steel heat exchanger, through which the coolant (water) circulates.

Recommendations for selection

Power boiler - main technical indicator, which requires special attention when choosing. The larger the area of the home, the more energy is needed to heat it and the greater the power of the heater should be.

Reference! For heating the area 10 square meters required one kilowatt thermal energy (at ceiling height 2.5 m.). Therefore, to heat a dwelling with an area 250 sq. m. you will need a boiler with a capacity of 25 kW.

Fuel suction depth is also an important characteristic. Tanks are often buried in the ground, the deeper the tank is, the greater the depth of diesel fuel suction should be. When choosing, the design features of the boiler are also important.

- Boilers can be single- or double-circuit. Single-circuit - heats the coolant in the heating system. In the second circuit, water is heated for showers and household needs. When choosing a device, take into account that heating water takes 25% power.

Photo 2. Single-circuit floor-standing heating boiler, equipped with an electronic control unit, easy to operate.

- Boilers differ in the type of combustion chamber. In devices with an open combustion chamber (atmospheric type), the air for burning diesel fuel flows by gravity. A regular chimney is built to remove flue gases. In closed combustion chambers (turbocharged), fans are built in that pump air onto the burners. Such a device requires a coaxial chimney, which is carried outside the house through the wall.

- There are boilers condensation and classical. Condensing units have built-in additional heat exchangers, which increases efficiency. Flue gases at the outlet have a low temperature, the resulting condensate is discharged into the sewer. Such models save 10–15% diesel fuel. Classic boilers are cheaper.

- Boilers differ in the type of control. Expensive models have a built-in electronic control unit, some devices have a remote control. Simple ones have mechanical control, it is simple and reliable.

Rules for using the boiler

For normal operation of the device It is important to comply with the requirements, specified by the manufacturer.

They concern the boiler room, the quality of diesel fuel, installation and operation regulations, compliance with environmental standards and fire safety requirements.

Requirements for the installation room

The heater is installed in a boiler room separated from residential and non-residential rooms by a partition made of non-combustible materials. If the boiler capacity is from 60 to 350 kW, it is placed in a technical room outside the house.

The boiler room is being set up supply and exhaust ventilation. The presence of windows and vents is mandatory. The width of the window openings depends on the operating rules of a particular device.

The floor and walls are covered non-flammable materials (ceramic tiles, brick, plaster). The ceiling is covered with gypsum fiber board.

The chimney is installed in accordance with fire safety regulations. A chimney is built at the point where the pipe is exited. cutting from non-combustible materials.

Quality of diesel oil

The quality of diesel fuel is determined by the requirements Technical regulations and state standardsoperating in Russia.

These documents regulate the fractional composition, pour point, cloud point, viscosity, fuel density, sulfur content, resins, and flash point.

Fuel manufacturers offer to buy diesel fuel for boilers with the following average characteristics:

- cetane number - 40–45;

- boiling point - 240–400 °C;

- density (at +15 °C) — 813.7 kg/m3;

- presence of sulfur - 0.508%;

- viscosity - 5–9 mm2/s.

Attention! They store diesel fuel in closed metal containersto prevent mechanical impurities, water and other liquids from getting into the product.

Calculation of the amount of fuel for the boiler

To receive 10 kW thermal energy is spent 1 kg of diesel fuel (per hour)The permissible deviation from the standard is 5–10%.

If the consumption differs from the standard by 20% or more, diagnostics of the heat generator is required.

Based on this norm, they calculate required amount of diesel fuel per day, week, month and for the entire heating season. The calculations take into account how the heater will operate (at full or partial capacity).

Example calculation:

- The boiler (10 kW) consumes 1 liter of diesel fuel per hour, 24 liters per day.

- The heating season continues 80 days, of which 40 — the heater is running on 100% power, the rest of the time - on 50% power.

- 24 liters * 40 days = 960 l.

- 12 liters * 40 days = 480 l.

- 960+480=1440 l. for the heating season.

The calculation is approximate. Fuel consumption is adjusted based on weather conditions.

Safety precautions

The boiler is regularly inspected to prevent fuel leaks. The owners of the house monitor the presence of diesel fuel in the tank, when refilling the fuel of the device, turn off and close the valve in the fuel tank. The tank is covered with a lid to avoid contamination of the fuel.

To prevent boiler breakdown nozzles, working parts and chimney are cleaned before and after the heating season. At the end of the heating season, it is recommended to turn off the power supply.

Important! In the boiler room You can't store fuel reserves, other flammable liquids, flammable materials.

Useful video

The video shows the start-up of a diesel boiler for heating and talks about various installation requirements.

For heating what types of rooms is it suitable?

Diesel boilers are suitable for heating one- and two-story houses with water heating. They are also used to heat large greenhouses.

These devices provide stable heating of large areas (100-400 square meters and more). Diesel boilers are suitable for heating in all regions, including the Far North.