You will hardly have to spend any money on fuel for it! Boiler for heating on waste oil

In matters of heating, people are more often guided by the problem of economy. That is why waste oil heating boilers have gained their popularity.

The term “working off” already means used oil that has been in primary use. Liquid can be synthetic or natural.

Heating oil will do both obtained from cooking utensils and from diesel locomotives or cars. Regardless of its origin, during the combustion process the liquid will release the required amount of thermal energy. Therefore, having such a device is very beneficial if there is direct access to fuel.

Content

Advantages of waste oil heating boilers

Heating boilers using waste oil have many advantages.

Economy

The boiler operates on previously used oil. A properly configured device will burn it out completely..

More often, such devices are purchased by people who have access to unlimited quantities of fuel.

For example, workers at depots or machine-building plants. But even if the waste liquid has to be purchased, then you will still come out on top.

The cost of the oil is minimal and it is used economically. The oil burns out completely, which means that every penny spent on it will be worth it.

Autonomy

This type of boiler operates autonomously, without connection to a stationary heating system. The buyer independently, regardless of the centralized heat supply, decides where the device will be installed. This is relevant in private houses, where autonomous heating is extremely necessary in the cold season.

Simplicity of the device

The device is so easy to assemble and operate, that some craftsmen try to assemble it themselves. The operating principle of a homemade and purchased unit is similar, and the resources spent on manufacturing or purchasing are almost the same.

Affordability

It is no coincidence that such heating devices are extremely popular. Despite the fact that there are few manufacturers of such devices on the market, they do not overcharge, as they understand perfectly well that such a device can be assembled at home. In combination with the low price of fuel, the consumer can recoup the cost of his purchase in the first heating season.

Photo 1. Two boilers (yellow and red) operating on waste oil. Manufacturer Thermobile.

Wide range of applications

Waste oil boilers are used not only for heating residential premises. They can often be found in offices, institutions, and even industrial and warehouse areas. It is these factors that have influenced the fact that such devices have received a wide range of applications.

Eco-friendliness

The fuel burns completely. In this case no toxic waste or harmful substances are released into the surrounding atmosphere. The device operates absolutely harmlessly for people and the environment. Many models of manufacturers are marked with the eco-safety mark from various environmental organizations.

Efficiency of use

The device quickly heats the air and the room around it, maintains the set temperature. The heat is felt almost immediately after turning on the device.

Not only does it remain in the room and not disappear over time, but it also spreads to other rooms.

Disadvantages of using waste oil heating boilers

There are also disadvantages to waste oil heating boilers.

Frequent maintenance

Along with the advantages, there are also disadvantages that every future buyer should be aware of. The first of these is frequent maintenance.

Such The devices require proper maintenance. Some models require cleaning of the combustion chamber of the hot water boiler a couple of times a month.

It is necessary to clean it from the remains of waste fuel as the filter becomes dirty, which needs to be checked. at least once a month.

Basically the device equipped with reusable filters, but owners should not forget that they can easily break down. The instructions for each boiler contain information about the need for maintenance. If the equipment is used in accordance with the instructions, then maintenance can be carried out no more often than indicated in the instructions.

Ventilation is mandatory

Despite the fact that waste fuel does not emit harmful substances or combustion products into the atmosphere, the vapors are quite strong, and If there is no ventilation, they will settle on the ceiling and walls. This will damage the appearance of your premises, spoil the materials, and also create an unacceptable climate for the operation of such a device. Therefore, make sure that the device is located in a place with well-functioning ventilation.

Fuel storage

Spent fuel does not require additional filtration before use, but It is necessary to take the necessary steps to store it properly.

It should not be exposed to high temperatures or direct sunlight. It is best to store in special containers intended for oil liquids.

Photo 2. Storing waste oil in special canisters. The walls of the products must be thick.

Their volume will depend on the power and amount of fuel consumed by the device. Each owner of a boiler should have at least two containers. One is small, consumable, and the second is for collecting and storing used oil.

Attention! There is no need to stock up for future use with a large amount of fuel. Firstly, it burns quite slowly, so most of the oil will remain for the next season. Secondly, the presence of flammable liquids in residential premises is unsafe for others.

Noise during operation

Unfortunately, a boiler operating on waste oil creates certain noises. This happens due to the operation of the fan and exhaust system. Therefore, it is advisable to install such equipment away from living rooms and rest rooms. The noise is quite loud and can interfere with healthy sleep.

Types

Waste oil boilers are divided into pyrolysis and turbo heaters.

Pyrolysis

This equipment made of sheet steel using steel pipes.

After manufacturing, the device is coated with heat-resistant paint. All elements form a single structure, where only the cover is detached from the combustion chamber.

The design of the device is simple. It includes:

- control unit;

- built-in fan;

- remote oil pump;

- combustion chamber with water jacket.

In the device the burner is missing.

Operating principle such devices are simple:

- Into the supply tank waste fuel is poured in through a hose, it is fed into a special chamber.

- The evaporation chamber is made of thick steel, is heated to a certain temperature.

- As it warms up, the oil starts to evaporate at the bottomThe released steam rises into the combustion chamber.

- In its center there is a perforated pipe, which supplies air from the fan.

- Oil heated The vapors mix with oxygen and burn.

- As a result of this process the water jacket is heated from the inside.

- The vapors are directed to a gas-tube heat exchanger.

- Passing through the water jacket, the vapors cool slightly and are fed into the room.

- Energy is transferred to the coolant. The combustion products themselves rise through the ventilation and leave the room.

Important! The main difference from other waste oil boilers is the absence of burners, which increases the reliability of use and also affects the ease of operation. The design is very compact and easy to install.

Turbo burners

The operating principle is similar to the functioning of diesel devices. It consists of the fact that the fuel is sprayed and the oil mist itself burns.

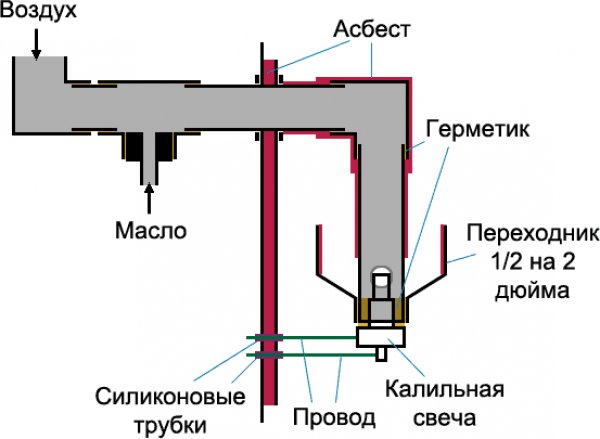

Photo 3. Schematic diagram of the turbo heater device operating on waste oil. The arrows indicate the components of the structure.

The distinctive features of such a device include: sensitivity to fuel quality. If it contains various impurities or water, the burner will not start. Good electrical power is needed.

This device operates according to the following scenario:

- Oil is poured into a special compartment.

- Under the influence of the flow of air masses it falls into the immediate combustion area. There is already a set temperature there.

- The pyrolysis effect occurs.

- Gaseous volatile products are released, which mix with oxygen and exit the hole. There they burn.

- At the same time, resinous products begin to accumulate in the compartment.

- After the burner is turned off, the temperature, having reached its maximum, is maintained.

- The air supply also does not stop.

- Non-volatile pyrolysis products are retained. The burner cleans itself.

The whole device consists of hard metal alloys. Covered with heat-resistant paint on top.

Terms of Use

In order for the boiler to serve for a long time without maintenance, it is necessary to pay attention to the rules of use.

Fuel

Waste oil for boiler operation can be used for almost any purpose. The main thing is that it meets a number of requirements that are put forward by device manufacturers.

Photo 4. Draining used oil into a special container. The liquid itself is dark brown.

If you have additional filtration systems, feel free to use them. The cleaner the used oil, the more efficient the combustion process will be. This also affects the fact that you will carry out less preventive maintenance during operation.

If analysis reveals that the fuel contains a large amount of water and antifreeze, then It is necessary to filter the fuel completelyThere are special recommendations on how to remove such impurities.

Manufacturers most often recommend using hydraulic, motor, transmission oils, and also Automatic transmission oil. However, it is not recommended to use fuel oil in the device.

Calculation of fuel for the boiler is carried out in accordance with heat loss for each specific room. It is necessary to take into account the data on the insulation of the place, its glazing, the boiler operating mode, as well as the required set temperature. Depending on the manufacturer, the calculation will be performed according to individual formulas. It is better to contact the manufacturer directly to clarify this issue.

The most commonly used is the following formula:

B = d*(h1-h2) + d*(h1+h2) /qn

Where: h1 — efficiency factor,

h2 — enthalpy of fuel,

d — heat of combustion of fuel,

qn — temperature and specific heat capacity of oil.

How to properly and safely fill the boiler with fuel?

Before starting work, you need to carry out a number of actions that will ensure the safety of using the device:

- Open the container with liquidThis is necessary so that it has time to interact with oxygen.

- After that Disconnect the device from the network and power supply, check the degree of sealing of the seams.

- Fill the collection bin with oil. Need to pour 10mm layer. The oil must be clean.

- Add 100 ml of kerosene to this liquid.

- Take the wick And soak it in kindling.

- Lower it to the bottom of the container.

- Set the waste on fire.

- Watch how the seams and oil behave. All actions must be carried out with gloves.

- Close the lid.

- After this, the device will start working., and you will be able to check how effectively it functions.

Photo 5. Filling a homemade boiler with waste oil. Fuel is poured into the lower part of the unit.

Do not allow oil to come into contact with foreign areas and parts of the device. All parts must be covered during operation. additional oxygen supply sources, for example, doors or windows.

How to maintain the oven?

The waste oil boiler control system ensures simple and fairly trouble-free maintenance of the unit. The buyer is required to perform three actions during the working season:

- Cleaning the heat exchanger

To carry out such a procedure, It is necessary to find access to the boiler. In most cases, this is provided by a removable rear panel. Once you get rid of it, you can remove soot and combustion products yourself, without the help of specialists. First, use dry cleaning techniques, then go over with a damp cloth.

- Replacing injectors

If your device has been running on waste oil for a long time, the need to replace the injectors may arise. already in season 1. Fuel is supplied directly to the burner, the combustion process occurs under pressure. Nozzles burn out and require replacement. Remove the nozzles and find the appropriate size. Install according to the instructions.

- Cleaning the fuel filter

Oil, primarily machine oil, contains a huge amount of small fractions of metal and other substances.

All of them settle on the filter, clog it, and because of this the device stops functioning properly. Filters are changed at least once per season.

This procedure will protect the injectors from contamination and, accordingly, burnout. All other systems and devices function without the need for various hygiene procedures.

Useful video

Watch a video that explains how to properly start a waste oil heating boiler.

Results

Waste oil boilers - an ideal option for economical heating during the cold season. They cope with the task equally well, working both in residential premises and in industrial zones. And the low cost of such a unit is a pleasant addition and another reason to buy.