One fuel load and you can forget about it for several days! Solid fuel boiler of long burning

Solid fuel boilers, despite widespread gasification and electrification, are very popularWood as a fuel is widely available and inexpensive.

Designers are constantly working on improving heating equipment, since archaic designs have low efficiency and are very inconvenient.

To make operation easier, long-burning fireboxes were invented.

Content

Selecting a design

To ensure maximum boiler efficiency, designers the following tasks have to be solved:

- Efficient combustion of fuel. There are two approaches: combustion with excess oxygen and pyrolytic decomposition of gases.

- Dosed automatic fuel supply or layered combustion.

- Placement of a heat sink around the combustion chamber or in the path of combustion products.

Depending on the implementation of these tasks designs from different manufacturers differ significantly.

Types of boilers by power

The choice depends on the tasks that are set for heating. The first thing to determine is purpose of the boiler.

Industrial

Intended for for heating large buildings, drying chambers, heating equipment. The capacity is calculated based on the needs for thermal energy, often the boiler is selected 25-30% more powerful. The design requires a separate boiler room, complex piping and automatic control, operation and maintenance are carried out by trained stokers.

Photo 1. Industrial type solid fuel long-burning boiler connected to the heating circuit.

The design is aimed for automatic reloading and pyrolysis decomposition of wood. At enterprises where waste is wood shavings and sawdust, this fuel is used predominantly. In this case, bunker loading systems with auger routes are used.

Domestic

Designed to improve comfort of use. Maximum autonomous combustion time, the ability to control the coolant temperature depending on the season, energy independence, type of fuel - all these features are taken into account when choosing the type of boiler.

Types by fuel combustion method and design features

Combustion is the process of rapid decomposition of wood into gases followed by oxidation of carbon to carbon dioxide. Optimal combustion always emits a large amount of heat. There are various ways to increase the burning time and efficiency of wood.

Grate

Combustion takes place on grate bars, through which air passes. The fuel burns in its entire volume, the intensity of the flame is regulated by the supply of air through the ash door.

In long-term combustion mode, such a boiler is ineffective, since combustion is slowed down by a delay in air supply.

Most of the wood decomposed into pyrolysis gases does not burn and settles on the walls of the chimney in the form of soot. The optimal option for using such a boiler is forced combustion mode And accumulation of thermal energy in a heat accumulator.

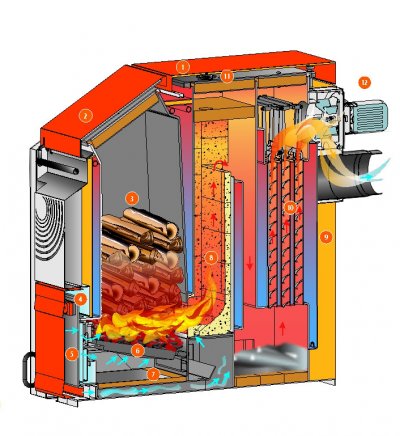

Pyrolysis

Pyrolysis boiler provides long burning of one batch of firewood thanks to the layer-by-layer decomposition of firewood into pyrolysis gases with subsequent combustion. Combustion in such a firebox does not occur over the entire mass of the load; only the required amount of fuel burns in the gasification chamber. Heat is obtained by burning pyrolysis gases and is captured by a heat exchanger on the chimney. The use of pyrolysis is possible only in a fairly narrow range of power; this parameter should be treated very meticulously.

Photo 2. Internal structure and operating principles of a solid fuel boiler of long burning pyrolysis type.

A significant disadvantage of pyrolysis boilers is their energy dependence. To maintain combustion of gases and decomposition of solid fuel, air is forced in by fans. This disadvantage is accompanied by an undoubted advantage - due to the forced air supply it is possible to precisely regulate the temperature of the coolant with stable combustion. The equipment is automated, with bunker fuel supply (sawdust, pellets) a phenomenally long time of autonomous operation is achieved.

Big advantage pyrolysis boilers - their relative omnivorousnessWith some adjustments and design features, pyrolysis occurs on husks, straw, sawdust, pellets, piece wood, bark.

Top burning

A revolutionary approach to increasing the burning time on one tab - to force the fuel does not burn in its entire volume from bottom to top, and layer by layer, from top to bottom.

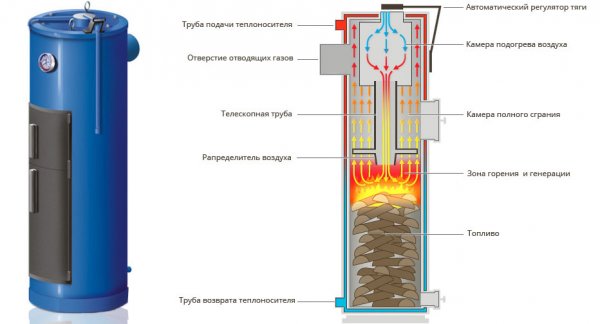

Photo 3. External and internal structure of a solid fuel boiler with upper combustion type. The arrows indicate the parts of the device.

The device is simple: the combustion chamber is filled with firewood, air is supplied through a differentiated system of air ducts. Combustion occurs only on top of the load, with sufficient air supply the fuel burns completely.

The design features of the boiler determine the type of fuel used. If possible, the bookmark must be tight, so that the coals do not fall down and form new fires. The equipment works on large pieces of wood, but they will have to be sprinkled with sawdust, chips, pellets. The main thing is uniform distribution of fuel by the area of the chamber.

It is impossible to heat with coal or peat briquettes, because it is a fuel with high ash content. Also, due to increased ash formation, wet wood cannot be used.

Shaft type

Improved design of top combustion boilersAir is supplied through a special telescopic air duct on which a cargo “pancake” is installed.

The fuel burns gradually from top to bottom, pressed by massive hot metal. The flame is fanned by air supplied directly to the combustion zone.

The design is brilliantly implemented in the products of the company "Stropuva", has been copied and improved many times by thousands of designers and craftsmen.

The design attracts attention with its amazing flexibility of settings, simplicity, durability, phenomenal efficiency and burning time. The boiler operates independently, without the use of fans and blowers.

Fuel loading should be as uniform as possible. The boiler works perfectly on any dry wood: wood chips, sawdust, straw, piece firewood, small logs, pellets. With pellets, the burning time increases significantly, so the boiler needs to be loaded less often.

How to choose a solid fuel boiler with long burning

The choice is influenced by the following:

- Budget. The cost of foreign-made equipment can be so high that instead of purchasing such equipment, the house can be heated for ten years with electricity or gas. The price of the boiler should be optimal.

- Available fuel. The most convenient fuel is pressed pellets. They have good calorific value and are convenient for loading mechanization. The problem is price and availability. If you have the opportunity to buy dry hardwood fuel or dry it yourself, you can buy any boiler.

Photo 4. Pellets in the form of small cylindrical granules. They are used as fuel for solid fuel boilers of long burning.

- Terms of Use. For powerful heaters, you will have to build a separate boiler room and install an insulated chimney made of stainless steel or ceramics. This significantly complicates the task and inflates the budget.

- Tasks that are set before the boiler. If there is a need to visit the furnace only once a week, you will have to purchase a shaft-type device with the ability to operate on coal, or a pellet boiler with bunker loading and fire with pellets. Such a system is expensive, and if there is no need, it is better to pay attention to simpler "omnivorous" devices.

- Durability of equipment. The more complex the design, the higher the combustion temperatures, the worse the metal, the more often you will have to repair or replace the boiler. Depending on the design, the cost of maintenance and repair will vary significantly.

How to operate the device

Optimal operation of any equipment depends on the operating mode and fuel characteristics. To prevent soot and condensation from forming in the air ducts, the firebox must operate in the optimal mode. "Strangled" operation with insufficient air leads to a sharp decrease in efficiency: the boiler consumes a lot of firewood. It burns for a long time, but heats poorly.

Boiler room

The boiler room has the following important parameters:

- Isolation. Smoke from kindling should not enter living quarters. It is optimal if the boiler room is arranged outside the living quarters, in a separate building or room with access from the street.

- Volume and ease of maintenance. The equipment is installed on the foundation, with free space provided around it for easy access to the piping units, damper, and cleanings.

- The presence of a chimney and ventilation. Solid fuel boilers with long burning are prone to increased condensation. A brick chimney is not suitable - condensation will penetrate through the masonry. It is worth using stainless steel sleeves, ceramics.

Fuel

Solid fuel boilers will operate in the long-burning mode only if there is the appropriate fuel. There are no miracles - to obtain a kilowatt of energy, you need to burn a certain amount of energy carrier. The amount of fuel is calculated simply: you need to know the calorific value and multiply it by the boiler efficiency.

Firewood. Only dry wood should be used, preferably hardwood. The preparation costs will pay off with trouble-free heating operation.

Pellets. The manufacturer supplies ready-made high-calorie and technological fuel. Pellets are bulk, but do not leave waste. They were invented to facilitate the transportation of industrial waste. Pellet furnaces are easy to automate, with large bunkers, the boiler can burn for months without human intervention!

Sawdust, wood chips. Application of wood processing waste has 2 problems: moisture and debris. Sawdust has a fairly low density and therefore low calorific value.

This is compensated by the cheapness of fuel; many enterprises give it away for free or for next to nothing.

Bulk plant residues: straw, cake, husk. A new word in alternative energy is the use of renewable fuel. Residues from production, straw, sunflower stalks and other local fuels were previously disposed of as waste. The use of such fuel pays off due to its low cost, but it is worth using if there is a constant opportunity to purchase a new batch.

Difficulties in storing and transporting bulk fuel are solved using containers, big bags, and packaging in paper bags.

Attention! You can't store such fuel in a large pile! The moisture condenses, the fuel begins to rot, overheats, and there is a risk of spontaneous combustion.

It is more convenient to store in bags placed on shelves to allow air access.

Rules for safe use

- Chimney device. Fires start exactly where the chimney passes through the ceilings. Good thermal insulation of the chimney and compliance with the operating rules will protect against fire.

- Periodic cleaning of the heat exchanger and chimney from soot. Soot can catch fire in uncleaned chimneys. Soot combustion temperature above 1000 °C, while a huge number of sparks fly out of the pipe. Danger! There is a huge risk of fire!

- Do not leave open flames unattended.Do not entrust heating to children or people with mental disabilities.

- Long burning boilers are technological devices. Read the instructions carefully and follow the manufacturer's recommendations.

How to determine boiler efficiency

After installation, the boiler must be tested. To do this, the firebox is filled with a weighed portion of homogeneous dry firewood, the heating system is connected.

Three parameters are measured: water volume, initial temperature, final temperature, combustion duration. Based on this data, the amount of energy transferred to the coolant is calculated.

The resulting value is compared with the calorific value of the fuel. If the numbers differ by 20% — the system works “perfectly”.

Useful video

Watch the video, which talks about the features and operating principles of solid fuel long-burning boilers.

Conclusion

A correctly selected boiler fulfills the obligations assigned to it - Heats the room for a long time, works without fading or smoking. Soot formation is minimal. A good boiler requires minimal human attention, is easy to maintain and does not require repair.