One load for several days! Solid fuel boilers of long burning with a water circuit

Solid fuel boilers with long burning are suitable for heating houses of any sizeThe device heats water, which circulates through pipes and radiators.

This happens in a special department.: double wall (container) between the insulated body and the firebox.

This layer is called water jacket, the main functions of which are the accumulation of coolant and its rapid heating.

Content

Schemes of solid fuel boilers of long burning with a water circuit

The devices differ in size, fuel combustion methods, duration of combustion of one batch of materials, water circulation features, design, complexity of automation (or its absence), and maintenance specifics. Externally, models from different manufacturers differ in design.

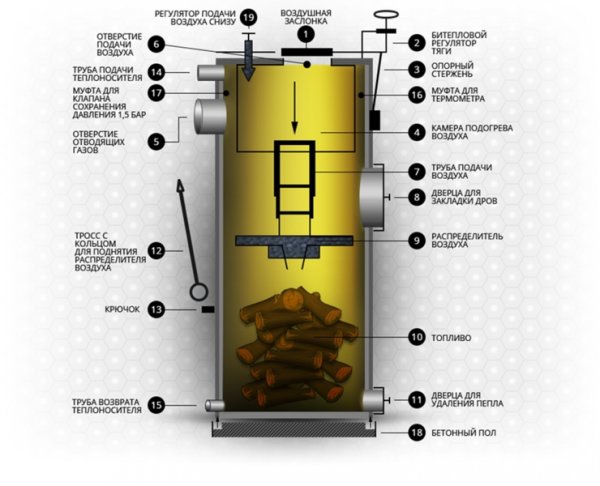

Photo 1. The structure of a solid fuel boiler with long burning. The arrows indicate the main parts of the structure.

There are several schemes of heating devices operating on solid fuel. But these units have a common operating principle and basic design elements. The diagram includes the following parts and devices:

- body (thermal insulating casing);

- fuel loading hatch;

- water compartment (water jacket);

- combustion chamber (furnace);

- grate;

- ash pit;

- ash pan;

- dampers, hatch doors, valves;

- hole for the chimney.

Operating principle

The operating principle of a solid fuel heater is as follows obtaining thermal energy from the combustion of any solid organic fuel at high temperature (200—850 °C and above).

Hot combustion gases give off heat to the heat exchanger. The role of the heat exchanger is played by the internal walls of the furnace, behind which there is a water jacket.

The device heats water, which circulates through pipes and radiators. The liquid flows in a closed circuit and returns to the boiler.

Long-burning devices are designed not only for heating water in the heating system. According to the number of heating systems, they are divided into single-circuit and double-circuit.

Single-circuit device

This device is intended only for heating the house. The liquid is heated by the heat of burning fuel and hot furnace gases. The optimal heating temperature of the device is 60-85 °C.

Hot liquid flows naturally or is forced (using a pump) into the pipes of the house’s heating system. The coolant circulates in a closed circuit, consisting of water pipes and radiators located in the rooms. The water gives off heat, cools down and enters the boiler again. The circulation continues while the combustion process of the fuel takes place in the firebox.

Reference. In some models, a water jacket is built into the main circuit emergency cooling coil. Cold water circulates through it, which prevents the coolant in the water jacket from boiling.

Dual-circuit device

The device is designed not only for heating, but also for heating water for domestic needs.

The diagram of such a boiler is identical to the diagram of a single-circuit unit, but there are a number of differences concerning the second heating circuit.

Heating part of the second circuit (DHW circuit) It is a system of pipes in the form of a coil, built into a water jacket.

The liquid in the coil is heated indirectly (heat is removed from the water jacket of the first circuit).

Hot water from the second circuit goes to the shower and kitchen. For cold water supply, mixers are installed.

The second circuit heats domestic water well only in the case of active fuel combustion. When the temperature of the liquid in the jacket drops below 60 °C, domestic water will be slightly warm. The DHW circuit has low productivity (up to 8-12 liters per minute).

The problem of heating household liquids is solved by electric boiler. During the heating season, the water in the boiler is heated by heating pipes, and in the summer and off-season - by an electric heating element.

Recommendations for choosing a boiler

The selection of a solid fuel boiler is influenced by a number of significant factors. Of great importance are:

- type of house (premises);

- heater design type;

- purpose of using the device.

Type of premises

The ability of a home to retain heat is extremely important when choosing. The "warmest" are new ones. houses made of brick, logs, panel buildings.

They do not experience heat loss through cracks in building materials, doors and windows, or poorly insulated ceilings.

Therefore, such buildings heat well. medium power units. The owner of the house calculates the heating capacity independently or with the help of a heating specialist.

The calculation is based on the height of the ceilings and the area. Thus, in the middle zone on an area of 10 m2, at ceiling height 3 m, it is necessary to generate 1 kW thermal energy.

Heater design type

Depends on the calculated power of the unit and the availability of fuel. Depending on the design features Long burning devices are divided into:

- pyrolysis;

- mine;

- automatic.

Pyrolysis boilers. In heaters of this type, the process of fuel smoldering occurs due to a lack of oxygen, which leads to the formation of combustible gases.

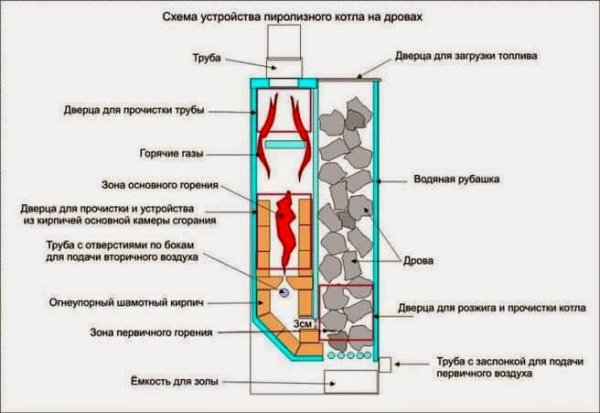

Photo 2. Diagram of the device of a long-burning wood-fired solid fuel boiler of the pyrolysis type.

The firebox of the device is divided into two partsIn the lower compartment, combustion and pyrolysis occur, and in the upper compartment, combustion of flue gases occurs.

After the fuel has completely ignited, the bottom hole is closed and the furnace switches to the pyrolysis gas generation mode. This is achieved using an automatic regulator.

Pyrolysis gas enters the afterburning chamber, mixes with air and ignites. In this case, burns up to 90% of smoke particles. The automatic boiler thermostat maintains the set afterburning temperature. Forced air circulation is provided by a fan.

Reference. In pyrolysis devices, the fuel is burned almost completely, therefore Frequent cleaning of the firebox is not required.

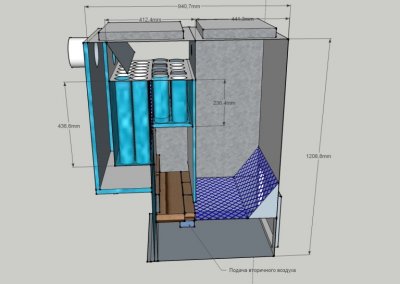

Shaft boilers — top combustion units, fuel combustion occurs from top to bottom. Structurally, they consist of two bodies — internal and external, between which there is a water jacket.

The vertical firebox of the heater is loaded to the top with firewood. Combustion air is supplied to the top layer of fuel using a telescopic pipe.

As the wood burns, it sinks under its own weight. Boilers of this type are capable of heating a house up to 7 days without additional loading and any service.

They provide constant and uniform heating of the liquid in the water jacket.

Automatic boilers. Designed for long-term operation in autonomous mode. Fuel is supplied from the bunker to the boiler via an elevator and auger conveyor. The bunker is located next to the device, in an adjacent room or outside the house. The consumption and supply of combustible material is regulated by automatic control devices.

These units demanding on the size of fuel pieces (granules), in most models the size of briquettes, pellets, pieces of coal should not exceed 30 mm in diameter.

Purpose of use

This is also an important factor in choosing. If the boiler is long burning is the main heater, no other devices are built into the pipe system. If the heater will be used as a backup, it will be necessary to install an expansion tank, perform additional calculations of the heating system, and coordinate the temperature schedules of the devices.

- If the unit is needed only for heating, choose single-circuit models.

- If the goal is to obtain domestic water, they prefer dual-circuit models.

- In non-electrified areas (or in remote areas with shortages, interruptions in the supply of electricity) they buy simple long burning shaft type boilers.

Operating rules

When using long-burning heating boilers, special rules must be followed.

Premises

The requirements for the premises are determined by fire hazard a heater in which heat is generated by an open fire.

The place for the solid fuel boiler is arranged in accordance with building codes and regulations. The location of the device is determined by its power:

- at power up to 60 kW the boiler can be installed in any room of the house;

- if the boiler capacity is from 60 to 150 kW, it is placed in a boiler room located in the basement, ground floor or any floor;

- at power from 150 to 350 kW The unit is installed in the basement, on the ground floor or first floor, in an extension or a separate building.

For each heater and communications, an area is allocated, as stipulated by building codes:

- a boiler with less power 30 kW allocate a plot of land 7.3 m2;

- 30-60 kW - 13.5 m2;

- 60-200 kW - 15 m2.

Attention! The minimum boiler room size for the lowest power appliance is 8 m2.

Walls and ceiling are finished with non-flammable materials. A concrete foundation is built under the boiler; for low-weight units, a non-combustible base is made. The base is covered with a steel sheet.

For solid fuel devices, only vertical chimneys are built. The boiler room provides natural and artificial lighting (30 cm2 for every meter of area plus a lamp).

To avoid carbon monoxide build-up Install exhaust ventilation. Fire extinguishing equipment is kept in a visible place in the boiler room. Fuel reserves, flammable liquids and materials are not stored in this room.

Frequency of use

Long burning boilers in winter they work continuously (with permanent residence of people). During thaws and in the off-season, the power of the heater is reduced, by regulating the loading and air supply.

Photo 3. Loading firewood into a solid fuel boiler with long burning. The fuel must be dry.

In summer and in the off-season, long-burning boilers are fired only when it gets cold. If the owners are absent for a long time, the devices are turned off and the water is drained to avoid damage to the device and pipes.

Safe Operation Rules

- A device with a water jacket requires careful attention to the temperature of the liquid heating. It must not be allowed to overheat or boil in the pipes.

- The boilers are heating up only those types of fuel that are specified in the instructions.

- Fuel size varies for different models, violation of this rule will lead to damage to the device.

- Cleaning of the firebox is in progress after the fuel has completely burned out.

- Chimney once per heating season cleaned from soot and condensation.

- During operation monitor the condition of pipes, radiators and water container, if leaks are detected, measures are taken to repair them.

- In case of breakdown of the pump, pressure gauges, other equipment The unit is stopped and a specialist is called.

Useful video

Watch the video, which demonstrates the installation process of the Prometheus long-burning solid fuel boiler.

How to safely test a finished boiler

Control of operation, the first start of the heater is best entrusted to to a heating specialist. Full control of operating parameters is achieved using a heat meter built into the system.

The meter allows you to evaluate the boiler power and compare it with the data in the passport; measure the efficiency; the time it takes to heat the liquid in the water jacket, buffer tank; measure the amount of heat released per unit of time.

The launch is carried out in the following order:

- fuel for the first ignition weighed, loaded into the firebox, lit;

- the dampers and flaps open according to the instructions;

- turn on the automation (if available), set the desired temperature;

- turn on the pump sensor heating system;

- position of dampers change after the fuel has ignited (according to the instructions);

- in models equipped with a fan, the air supply is automatically switched on and off;

- measure the water temperature on the inlet and outlet pipes of the heating system, the actual power of the boiler is determined;

- compare the power with that stated in the instructions.

Comments

Solid fuel long-burning boilers must be cleaned of soot and resin at least once every two to three weeks.

It is strictly forbidden to overheat the long-burning boiler, as this can lead to the destruction of the boiler and the heating system. For reliable operation of the automatics of long-burning boilers, it is necessary to provide it with an uninterruptible power supply and protect it from voltage surges.