More compact than a stove, but no less hot - a coal heating boiler

A coal boiler is indistinguishable from a stove, its design contains the same elements, but It is made from other materials and has smaller dimensions.

Therefore, its main function is to heat the home. But there are also additional options. Coal boiler with two circuits will provide the owner with hot water, and the hob will allow him to cook food.

The principle of operation of coal boilers for heating

Coal boiler consists of a solid body and facing panels. To reduce heat loss, there is heat-insulating material between the body and the panels.

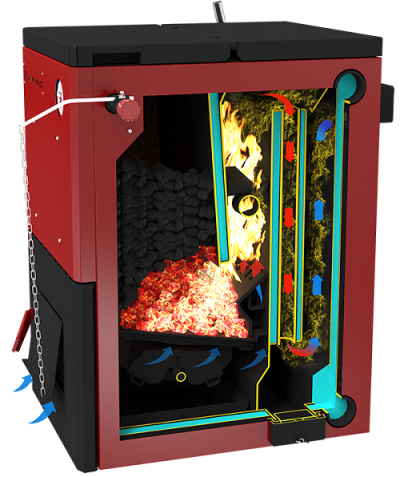

Photo 1. Coal boiler for heating with automatic loading. On the side there is a bunker in which there is coal.

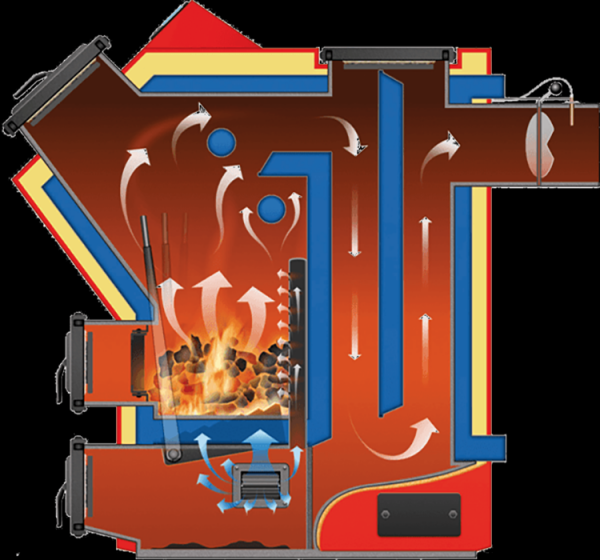

There are three cameras at the front. Each has a lid, the design of which prevents smoke from entering the room. The lower chamber serves to collect ash. At the bottom, on the back panel, there is an adjustable hole for forced or natural draft.

Coal is loaded into the central compartment (combustion chamber). The lower and central sections are separated by a grate, which facilitates direct air flow and waste removal. During combustion, warm air rises to the upper chamber and heats the heat exchanger. Heated water from the heat exchanger enters the heating and hot water supply system through pipes. The temperature is set using a chain draft regulator or electronics.

Coal boilers are divided into two large types: with manual or automatic fuel loading. Heaters first group require constant, 4-6 times a day, coal feed. They are not able to maintain a uniform temperature of the coolant during operation.

Boilers second group have an additional fuel hopper and an automatic feed system. After one loading they work up to 7 days. Automatic fuel supply constantly maintains the set water temperature in the system. Coal boilers are also divided by combustion method.

Photo 2. Schematic diagram of a coal-fired heating boiler. The arrows indicate its main parts.

Types of devices

There are several types of coal boilers for heating. They differ by combustion principle and by material manufacturing.

Direct combustion

These boilers are the cheapest and most common. Combustion in the system starts from the bottom, smoothly spreading throughout the entire chamber. The heated air rises and heats the metal heat exchanger, which transfers heat to water or another liquid coolant.

Efficiency such heaters about 70-75%. This is due to the design features. Most of the heated air does not have time to completely give off heat and is removed through the chimney. High fuel consumption — the main disadvantage of direct combustion boilers.

Long burning

Boilers of this type are distinguished by a complicated design. Here the heat exchanger is located not above, but behind the combustion chamber.

The fuel combustion system has also been changed. The coal is ignited not from below, but from above, and air is supplied from there.

Such heaters have an advantage over direct combustion boilers. Fuel must be loaded twice as rarely. But there are some peculiarities:

- The coal must be well dried. Otherwise, the boiler takes a long time to warm up, giving off little heat.

- Using wet coal will cause condensation., which, when mixed with ash, forms a foul-smelling slurry. This mixture gets into the firebox, which causes the boiler to go out. It can also clog the chimney or leak out.

- Often used only low-caking grades of coal.

- Devices of this type cannot be refilled.. Before filling the boiler, you need to wait until the fuel has completely burned. This feature is due to the fact that combustion occurs from top to bottom.

Important! It is necessary to strictly adhere to the recommended brand of coal. It indicated in the device instructions.

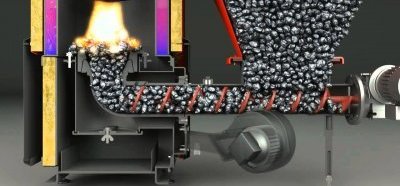

Pyrolysis type devices

Key differences from previous boilers: second combustion chamber and automation. After ignition, the control system stops the air supply. In the absence of oxygen, the coal begins to smolder and release a certain amount of combustion gases. The gases are forcibly delivered to the second chamber, mixed with air and burned. Thanks to this design Boiler efficiency approaches 92%, which allows for more efficient use of fuel.

Photo 3. Diagram of the internal structure of a pyrolysis coal heating boiler. The arrows indicate the direction of gas flows.

The disadvantages of pyrolysis boilers are the same as those of long-burning devices. Plus: Such heaters cannot operate without electricity.

Attention! All models of devices with forced air supply have a fan, the breakdown of which may cause an explosion due to accumulated gases. If the fan is broken, you need to put out the boiler, open the chimney and combustion chamber. This will allow the accumulated hot gases to escape.

It's time to talk about the material, from which the boiler is made. This is an important factor affecting the durability and maintainability of the heating system.

Welded steel body

Cheap The models of the devices have a body made of thin sheet steel. More expensive there are buildings 4mm thick made of heat-resistant or high-carbon boiler steel.

But they all have the same advantages and disadvantages. Pros:

- Due to its plasticity, steel able to withstand pressure and temperature changes, which slightly exceed the critical values. This means that the steel body will withstand small overloads, but the cast iron one will split.

- Steel is lighter than cast iron, which simplifies transportation and installation.

- Damage to the hull (cracks and seam breaks) caused by increased pressure, can be fixed with a welding machine.

Cons:

- Corrosion — the worst enemy of a steel heat exchanger. Rust will lead to the exhaustion of the walls and their burnout.

- Plain steel housings burn out within a few years.

- There is no possibility to increase the power boiler.

Cast iron as an alternative

The cast iron body consists of sections (plates) cast from a high-strength alloy. The plates are fastened together with bolts, and the joints are coated with a heat-resistant sealant. The design allows increasing the boiler capacity by adding sections. Such devices have a number of advantages:

- Cast iron is resistant to corrosion, which allows for increased boiler service life up to 50 years.

- The dimensions of the devices are relatively smallThis is possible due to the fact that the material retains heat well and the area of the heat exchanger is reduced.

- Ease of repair. The damaged section is simply replaced with a new one.

- Possibility of increasing capacity.

Flaws:

- Cast iron does not withstand sudden temperature changes well. Cracks in sections can form even with small vibrations.

- The brittleness of cast iron has a negative impact on transportation. Any shocks or impacts can damage the device.

- Efficiency is lower than that of steel boilers. It is not possible to manufacture a multi-pass heat exchanger.

Pros and cons of coal heating boilers

Advantages:

- Compared to other solid fuel boilers, coal units have an increased combustion time. Coal burns for about 1.5 times longer than firewood and 2-3 times longer than pellets.

- Any coal boiler works with different types of solid fuel. Firewood, pellets and sawdust are used. However, it should be taken into account that the power of the device will decrease by 25-30%.

- The simplicity of the design guarantees protection against accidental breakage. And targeted repairs can be done by anyone with a minimum set of skills. Roughly, the boiler is a cabinet with several compartments.

- Coal is a natural material. When burned, it is released into the atmosphere no harmful or toxic substances are emitted.

- Coal burns longer and produces more heat. This means that a device using such fuel is several times more economical than its analogues using other solid fuels.

Flaws:

- Even when using dried fuel, the boiler chimney will gradually become clogged. To clean it, you will have to call a specialist with a special vacuum cleaner or chemical reagents, which entails additional costs. It is possible to clean the chimney yourself, but to do this, you will have to completely disassemble it.

- The price of conventional coal boilers is comparable to gas modelsThe cost of pyrolysis units exceeds 100-200 thousand rubles. That is, if there is access to gas, then buying coal heaters is not profitable.

- Coal is sensitive to the environment and quickly absorbs moisture. Special attention should be paid to its storage. The room should be warm and dry. Using wet coal leads to a decrease in power and extinguishing of the flame. In addition, the chimney will become clogged faster.

- Models of heaters that use forced draft and automation - energy dependent. In case of power failure, the boiler will not be able to operate.

Useful video

Watch the video, which talks about the features of using a coal boiler for heating.

Basic safety rules and results

A coal-fired boiler is an indispensable source of heating and hot water supply, but only in the absence of gas. Its design is simple and reliable. The main disadvantage: the need to periodically add fuel.

To work safely with the boiler, you need to remember a few things:

- It is forbidden to drain or add cold coolant when the boiler is running. This will inevitably lead to a breakdown.

- It is necessary to keep the chimney clean to prevent carbon monoxide from entering the room.