Simplicity and ease of maintenance: the operating principle of a solid fuel boiler with automation

Solid fuel boilers are a profitable source of heat in non-gasified areas, where electric heating also seems impractical.

As the name suggests, the fuel used for such boilers is solid elements are used: firewood, peat, coal, pressed wood sawdust (pellets).

Due to the nature of the fuel, its constant supply, unlike, for example, natural gas, is difficult, therefore such systems require the user to constantly and periodically load fuel and removal of combustion products.

To simplify their operation, a new technology is being introduced various automation, maintaining the coolant temperature in accordance with the weather outside and (sometimes) providing fuel supply.

Sales of solid fuel boilers with automation

Automation is present on all types of boilers: classic, pyrolysis and long burning.

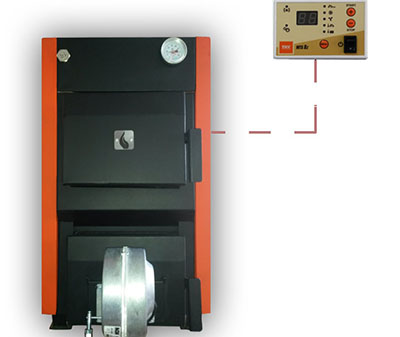

From simple mechanical systems to the most advanced: electronic with the ability remote control and monitoring via the Internet.

Any automatic electronic system for heating boilers consists of sensors (temperature, pressure, draft, flame), actuators and controller, controlling these devices according to a given program and readings from sensors.

Damper control

The damper is installed in any solid fuel boiler at the exit from the firebox in front of the chimney and serves to regulate the draft and the speed of removal of gases released during fuel combustion.

Correct adjustment of the damper valve significantly increases the efficiency of the boiler, and in its absenceOMost of the useful energy will simply “fly out the window”. And this causes increased boiler wear and the chimney from overheating.

Photo 1. Damper with electromagnetic drive for automatic solid fuel boiler, increases its efficiency.

The drive of the damper valve can be either electromagnetic, providing two positions (fully open - half open), and motorized, which will allow more precise control of the chimney cross-section.

Temperature sensor is installed in the boiler jacket. When the coolant temperature increases, the automation closes the damper, reducing the draft and lowering the boiler operating power; when it decreases, on the contrary, it opens and increases the power.

Fans

Another way to regulate draft is to use fans. for forced air circulation in the boiler. It is borrowed from industrial units, where efficiency plays an important role due to the volume of fuel.

Photo 2. WPA X2 blower fan for boilers operating on solid fuel elements.

Stand out two types fans for long burning boilers:

- Blower fan — is placed in front of the firebox instead of the ash pan door and affects the supply of oxygen to the firebox, thereby regulating the intensity of fuel combustion.

- Smoke exhauster — is placed either at the beginning of the chimney (immediately after the boiler) or at its end.

The main task is traction control, as well as its strengthening when natural draft is insufficient for efficient operation of the boiler (due to weather conditions or the design of the chimney).

Fan speed, and, consequently, their influence on the traction in the system can be smoothly regulated within wide limits using a thyristor control unit.

Attention! If the coolant temperature is insufficient, the controller increases the draft by changing the fan speed. If the boiler is too hot, the thrust decreases.

Ash pan door

The most common type of automation is adjusting the ash pan door opening (blower). Opening or closing the door changes the natural draft and affects the boiler temperature.

The simplest systems for adjusting the ash pan door are: thermomechanical. The device consists of a heat-sensitive liquid, a spring and a chain for connection to the door. It is installed in the standard holes of the boiler, where thermal contact with the coolant is ensured.

Photo 3. Adjustable ash pan door of a solid fuel boiler, as one of the automation options.

On the thermostat the desired temperature is set. When overheated, the liquid expands, overcomes the elastic force of the spring and weakens the chain, the door closes, the draft decreases, and the temperature drops. Otherwise, the door opens wider, and the temperature rises.

Important! Such systems do not require power and are reliable, but the accuracy of adjustment is limited. 5–10 °C.

Electronic systems use temperature sensors for controlling the coolant and electromechanical drives installed on the ash pan door. They work similarly, ensuring the accuracy of adjustment up to 1 °C.

Since electronic systems require constant power supply, it is worth taking care of the installation uninterruptible power supplies (UPS) to prevent the boiler from breaking down in the event of a power outage.

Pros and cons of an automatic device

Advantages:

- Autonomy: Solid fuel systems require regular fuel loading, sometimes up to 10 times a day. The automation increases the combustion duration and efficiency of the system, due to which the boiler needs to be monitored less often.

- Remote control: Advanced electronic systems provide control via the Internet or SMS, allowing you to monitor the boiler from anywhere in the world or start the heating in advance of your arrival.

- Accurate temperature determination and maintenance - eliminates the need to manually adjust the draft, reduces the impact of fuel quality on the stability of the system.

- Safety of use: overheated chimney, boiling of the coolant, all this can lead to dangerous emergency situations or even fire. Automatics free the user from the need to control the operation of the boiler and notify about emergency situations.

Flaws:

- Energy dependence: In the event of a power failure, the boiler may go into an uncontrolled mode, therefore, mechanical backup and uninterruptible power supply are necessary for automatic systems.

- Price: Although electronic boiler control systems are not overly complex, they are positioned a class above classic boilers, and their price is unreasonably high.

Recommendations for choosing long-burning devices

First of all, the boiler type is determined area of heated premises and the operating time of the system.

To select the power, use the formula: 1 kW heating capacity per 10 m2 area.

If the building is small and the heating is used periodically (for example, only on weekends), then a good option is classical solid fuel boiler with mechanical thermostat. It is inexpensive, easy to maintain and reliable.

If you are heating large areas for a long time, then it is worth looking away pyrolysis boilers or long-burning boilers, since high efficiency levels out the cost of fuel, and the higher price will pay off with savings on consumables. Pyrolysis boilers have two combustion chambers.

In the first, wood or coal burns in an atmosphere with a reduced oxygen content, releasing gases that then burn out in the second chamber. This allows for full use all fuel energy and eliminates the need for frequent loading of new portions (fuel is loaded 2-4 times a day).

Reference! In long-burning boilers, with the help of a special telescopic burner, solid fuel elements burn from top to bottom, so the firewood is loaded once every two days, and the coal burns up to five days on one load.

Useful video

In the video you can see how an automated solid fuel boiler is started and fired up.

Solid fuel boiler - a worthy alternative

Thanks to the latest developments in the field of heating systems, solid fuel boilers with automation are quite good compete with gas and electric ones.

There are both Russian and foreign manufacturers on the market. Domestic brands:

- Siberia;

- Viadrus;

- Hearth;

- Zota;

- Prometheus;

- Bourgeois K;

- Stropuva.

Imported boilers:

- Grandeg (Latvia);

- Faci (Italy);

- Bosch (Germany).

Boilers are very popular in Russia Stropuva, thanks to original developments, they operate on coal for up to seven days and are adapted to local climatic conditions.

When choosing, please note that domestic boilers cheaper, but automation of imported boilers more advanced, right up to their integration into smart home systems.

However, The first thing you should pay attention to when choosing is power boiler and type of fuel used, and based on this, give preference to a specific brand.