Instructions for thrifty owners: how to make a heating radiator with your own hands?

Homemade radiators for the heating system are capable of significantly reduce the cost of repairs. Most often, self-made registers are used for greenhouses, utility rooms, garages, and workshops.

Some use homemade (custom) radiators to add effect to the interior.

Radiators made by hand are much cheaper than even used ones. A big advantage of homemade batteries is the ability to freely "play" with shapes, it is easy to fit the dimensions into the calculated space.

How to make a radiator for your home with your own hands

A properly made battery is easy to operate, durable, does not leak, and has a neat appearance. To cope with its construction, you need to go through a series of stages.

Preparing the tools: photo

To make a radiator, you will need the following skills and tools:

- Metal compounds. To prevent the battery from leaking, the wall material is reliably soldered together. This can be done using soldering irons, a welding machine, or a gas burner. Of course, the tools also require welding skills - the seams must be beautiful, without slag inclusions and cavities.

Photo 1. Soldering iron ZD-200V, power 40W, power supply - 220 V, manufacturer - "Zhongdi".

- Measurements and markings. The work will require rulers, squares, tape measure, magnets. For installation or assembly of heavy volumetric batteries on site, a water level, bubble level, laser level will be required.

- Metalworking. Skills and availability of an angle grinder, hammer, chisel, file and other metalworking tools and devices.

Photo 2. Angle grinder model GWS 660, power consumption 670 W, manufacturer - "Bosch".

- Painting materials and tools. A brush, sprayer, primer, paint, degreaser, and thinner will help protect the product from corrosion and give it a fresh look.

Photo 3. Universal degreaser, capacity - 5 l, shelf life 36 months, manufacturer - "Vershina".

A well-equipped workshop will simplify the task and speed up the work considerably, and if some tools are missing, they can be rented or borrowed from friends.

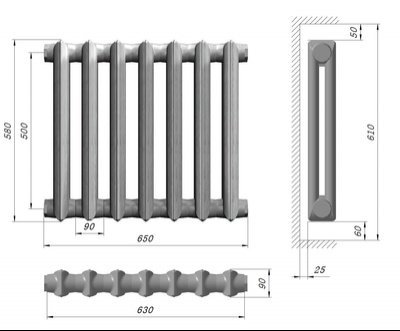

Calculation of heating battery sizes

The main characteristic of a radiator is its ability to transfer heat to the surrounding space. It depends on the property battery walls, area of parts, volume of coolant and its circulation speed.

The design of the battery begins with the preparation of the technical specifications: the required dimensions, the heat exchange capacity. The design of the radiator consists of the following stages:

- Calculation of heat loss in a room. The higher and larger the room, the greater the area of contact of the radiator with the environment. Each room is unique, as it has its own characteristics of thermal conductivity of the walls, quality of glazing, ventilation. There are reference books that allow you to calculate heat loss, but there are average formulas - heat loss of ceilings, walls, windows are added up, multiplied by correction factor of 20% — the required radiator power is ready.

-

From room shapes The number, size and location of the radiators depend on it. One radiator will not be able to heat a narrow long room, so additional ones are installed.

Heating elements should be installed near entrances from the street and under windows: when cold air enters the room, it is “cut off” by a flow of warm air.

- Define possible pressure and temperature in the systemThe design of the battery depends on these parameters - at high pressure there should be as few threaded joints as possible.

- The power of the radiator is affected by number of registers and distance between themIf the main type of heat transfer is radiant, there should be no space between the pipes. less than 50 mm. Otherwise they will heat up one another.

We choose a design solution for assembly

There are two technologies used most often for building batteries: radiator and convector. The radiator consists of edge-registers, located both horizontally and vertically. The convector can consist of ribs, onto which an air jacket or air duct ribs are welded to increase heat exchange and organize convection flow.

To make a successful battery that pleases the eye, it is worth analyzing the following parameters:

- Type of premises, where the radiator will be installed. For heating greenhouses, batteries made of long pipes are usually used, located in several rows near the outer walls. A custom heated towel rail for bathrooms has a different design - with shelves and hangers, a beautiful appearance is required.

- Available in stock materialsCopper or steel pipes of the appropriate diameter are suitable.

- Technology radiator operation. If it will heat the room with radiant heat, it is worth using register technology, to create air warm curtains it is better to use a convector scheme.

- Type of connection and water fillingTo easily remove the air bell from the battery, it is worth planning an air bleeder or an expansion tank connection at the top point.

Metal: copper or polypropylene pipes?

To ensure that the battery lasts a long time, specialized ones are used. metal water pipes. They are made using a special technology that turns the wall into a monolith. Even good folded joints, spot welding with sealant will leak over time. It is not advisable to use thin welded structural pipes of a square profile for batteries - round tap water is preferable.

The radiator pipe wall must ensure tightness and durability, as well as excellent heat transfer. "Black" steel for batteries has thickness 2-3 mm, "stainless steel" - 1-2 mm, copper - 1-2 mm.

Preparation of parts

The first stage of radiator assembly is cutting strictly to size. The error is no more than ½ the thickness. This way the joints will be even. Use Angle grinder with cutting disc for metal or cutting machineRarely does a workshop have a plasma cutter at its disposal, but in the West they are very popular.

Make a list of sizes - this will make the task easier and will help you not forget anything.

When marking square pipes, you can use square, the line is applied on all four sides.

To draw a round pipe evenly, wrap it in a sheet of paper in several layers, dip it in water and outline the boundaries of wet and dry, using a needle template.

They use it when working sharp scribers or chalk — the traces of the marks should be clearly visible.

When cutting parts, remember safety precautions.

Important! Use when working with an angle grinder protective glasses or mask, fragments of flying circles can cause serious injury.

To connect the battery registers you will need holes and precision fits. They are easier to make if you have a needle template and a step drill of the appropriate diameter.

Massive radiators they are already collecting on the wall. Provide the ability to weld into hard to reach areas before securing parts.

Welding of steel pipes

Only an experienced welder can connect the parts together. Tightness The quality of the seams directly depends on the tools used, the welding machine and the skill of the worker.

If you have no experience, be sure to study the theory of welding and practice on unnecessary parts. Only after achieving a good result, it is worth taking on welding the main frame.

When working, first set up and secure the parts. This will help one or two helpers, clamps, magnet. First, the structure is assembled using "tack welds". After welding, the part "leads away", internal stresses accumulate. If the main radiator frame is assembled by thoroughly welding joint after joint, then it will be difficult to weld the last parts on the battery.

What to cook with

With ferrous metal, the best results are achieved by welding with propane or acetylene torch, which allows you to obtain a smooth and sealed seam with excellent penetration.

Working with manual arc welding melting electrodes requires good skills. Use electrodes with a rutile coating, carefully adjusting the parts. While acetylene allows you to easily tighten even large gaps, high-quality electrode welding requires preparation.

If possible, it is worth taking advantage of it. semi-automatic weldingThis is a world standard that allows you to get an excellent seam with a minimum of skills.

You just need to set the voltage and wire feed speed correctly.

Stainless steel is welded as special electrodes, semiautomatic in an argon environment, and non-consumable tungsten electrode in an inert gas environment. The latter method is the most preferable - there is no need to clean the joints, a correctly executed seam serves as a decoration of the part.

Copper and alloys are joined together using rations. The technology is simple - the parts are cleaned, adjusted, lubricated with soldering paste or flux. Heating the part with a lamp to a temperature at 250-300 °C solder is applied to the joint. It immediately flows into the gap between the parts, firmly insulating them. The method is simple, but requires some skill and experience.

Welding recommendations

If you have the opportunity to invite a familiar welder with a discharge, be sure to do so. The quality of the product will increase several times.

Use only high-quality consumables for the manufacture of the radiator - mask, electrodes, mass holders. This will eliminate porosity and allow you to see the welding process.

Keep the arc short. Welding is a microdrop transfer of the electrode metal into the weld pool heated by the arc. A long arc "splashes" the metal, deposits slag - the radiator will leak in this place.

When replacing the electrode beat off the slag, it is precisely in the unwelded root of the seam that radiators most often leak.

Cook "points" with greater current strength. This way the seam will not be convex, the main thing is to quickly tear off the electrode so that there is no spattering and a long arc.

Keep the electrode at the same angle to the workpiece throughout the entire weld.

Be sure to look at welding bath — a liquid molten area near the arc. Only by controlling its width, depth of penetration and spreading can a high-quality weld be guaranteed.

If the seam is welded well, the slag is knocked off with one or two blows of a hammer, in its entirety.

Electric radiator

If there is no central heating system in the room, install an electric heating element in the radiator. However, the design of the battery will have to be complicated:

- The heating element inside the battery does not touch the walls of the pipes and is installed as low as possible.

- The water in the radiator should circulate easily through heating element.

- Add at the very top point expansion tank to squeeze out excess liquid. For this purpose, the upper register of the radiator is made with a slope.

- The material of the heating element body and the battery walls should not cause potential difference, since otherwise the joint will rust and let water through.

Copper

Copper is very easy to process. It is worth remembering that copper cooled in the air becomes stronger, but if heated copper is cooled sharply, it becomes soft and annealed.

Annealed tube It bends easily if you fill it with sand - a copper battery can be assembled into any shape.

Copper has two advantages when used in creating a radiator: excellent plasticity and corrosion resistance. This makes it possible to use relatively thin and light pipes.

They have the highest heat transfer coefficient. Accordingly, more tubes can be laid on the same area and the batteries respond faster to the antifreeze temperature setting.

The radiator register circuit will allow to avoid high hydrodynamic resistance even in case of small diameter tubes.

The only drawback is the significant price of the radiator.

Useful video

Check out the video that shows the process of making a radiator from a profile pipe.

Buy or make yourself

Better to buy ready radiator, assembled in factory conditions. If this is not possible, arm yourself with patience and a welding machine, and even if not on the first try, you will make a good sealed radiator.

The battery device is simple and does not require special plumbing skills, but It is important to connect all the parts well. The operation of the heating system depends on this, since it will be difficult to repair it during the cold season.

If you don't have sufficient welding skills, watch some training videos, read a welding textbook, talk to experienced people. Be sure to practice on unnecessary parts., and if the results are good, boldly and slowly get down to work on making the radiator.