Correct connection will not leave the batteries cold! Heating radiator connection diagrams

With the abundance of components for heating systems (HS), your eyes run wild; different installation schemes are used, even for connecting radiators are fundamentally different from each other.

It is important to connect them correctly, creating optimal conditions for the operation of the heating system. It is nice if the house is warm with minimal expenses. Correct installation of batteries is a guarantee of comfort at home.

Content

Features of two heating system options

In both private and apartment buildings, two fundamentally different systems of control are used: one-pipe - relatively budget-friendly, two-pipe - universal.

Single-pipe - "Leningradka"

Improvements in heating equipment technologies have increased the functionality and controllability of the Leningradka.

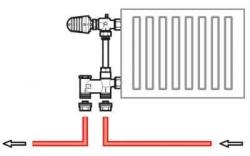

Photo 1. Connection diagram of the Leningradka heating radiators. The system is connected by one pipeline.

Consists of: boilers installed near the walls along the perimeter of the rooms of the batteries. Everything is connected by a single pipeline. Based on its position CO can be horizontal or vertical, with the pipeline possibly being placed at the top or bottom:

- With the pipes in the upper position heat transfer is better, but only with careful design. An additional device is installed - an acceleration section, this will increase the length and cost of the pipeline.

- Lower position of pipes easier to install, but the benefits are reduced by the need for a circulation pump.

The vertical position of the risers is advantageous for apartment buildings. In private houses, mostly horizontal pipelines - "beds". Type: open or closed, both are suitable for heating a small area. The optimal number of radiators is up to 5, usage 6-7 batteries requires precise calculation, from 8 — there are risks of reduced efficiency and costly modifications.

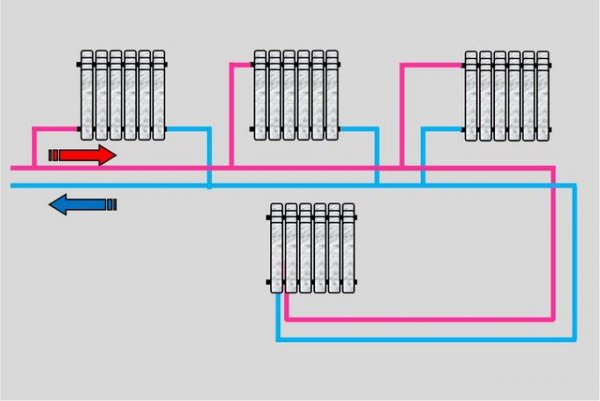

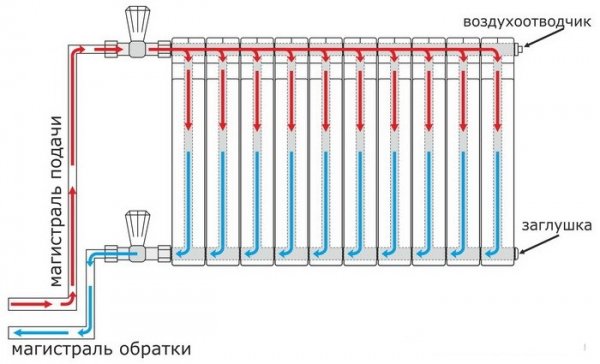

Two-pipe - parallel

Practical and most in demand. This is a closed circuit of a heating boiler and heating batteries. Each is connected to two separate pipelines: supply, through which the coolant flows into the battery, and return, through which it goes back to the boiler. The heated coolant is supplied to all radiators simultaneously through one pipe, and after giving off heat, it is collected in another, so the batteries work with equal heat output.

Photo 2. Two-pipe heating system. The supply circuit is shown in pink, the return circuit in blue.

Thus, the optimal heat engineering balance is stably maintained in the CO - the advantages are significant and obvious:

- Individual adjustment of radiators is available. Installation of control devices will ensure the set temperature.

- The small difference in pressure in the CO makes it possible to use economical low power circulation pump.

- Shut-off valves allow for repairs and additional installation radiators without stopping the CO.

- Works effectively in buildings of any size and number of floors.

The disadvantages of a two-pipe heating system are the complexity of installation and the increased cost due to the double number of pipes. However, using small diameters saves money — the final cost comes out a little higher, and the benefits are much greater.

Accessories for connecting batteries

Often, fastening and connection elements are not sold with the battery, but are purchased separately. The standard installation kit includes:

- Pairs of adapters, with right and left external threads — screwed directly into the battery, the internal thread for the shut-off valves is the same.

- Threaded plugto close unused outputs.

- Sealing paronite or silicone gaskets adapters and nipples.

- Profile or anchor fasteners radiator to the wall, or fastening to the floor.

Additional purchase required no less important fittings:

- Mayevsky craneto bleed air and restore the radiator's operation.

- Taps, thermostats, bypasses factory execution.

- Seals, optional - flax, fum tape, tangit thread.

All elements of the CO without exception must be correctly selected and joined. When installing high-quality boilers and radiators, you should not skimp on fittings.

Types of radiator connections and diagrams

There are several schemes for connecting batteries to the heating system, all of them varying degrees of effectiveness.

But specific initial conditions for the sake of design or to reduce cost do not always allow using the best of them, although the connection method is the main guarantee of comfortable operation of the heating system.

Attention! It is recommended to install shut-off valves for radiators using special ones. with detachable taps. Their cost is slightly higher than usual, and dismantling the battery with them is much easier.

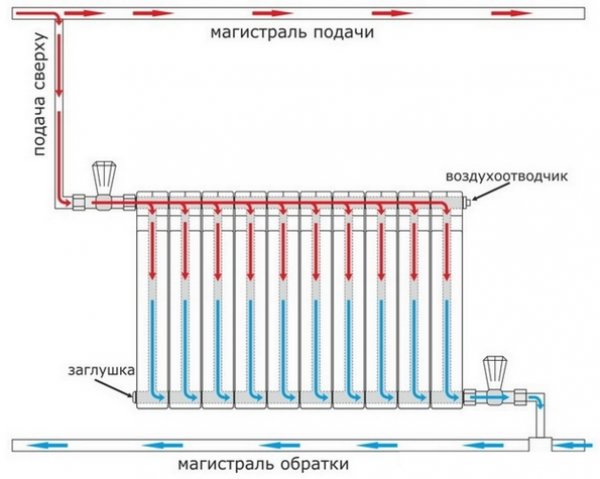

Top

Top connection of the supply pipeline creates a natural gravitational force — the heated coolant goes up until it gives off heat energy and partially cools down. Having given off heat, it becomes heavier and tends downwards, going into the return pipeline. Without a doubt — This is a good way to connect radiators, and the efficiency is maximum.

Diagonal method

Universal diagram for installing batteries for one-pipe and two-pipe systems, characterized by high heat transfer with minimal heat loss, effectively used with larger batteries of large area. The coolant is supplied to the upper or lower part of the radiator, and diagonally to the supply leaves, on the other side.

Photo 3. Diagonal diagram of battery connection. The supply line is in the upper left corner of the radiator, the return line is in the lower right corner.

Lower or saddle

This is a classic one-pipe "Leningrad" scheme, and in a two-pipe system it is more often used for the installation of hidden connections; to increase efficiency, special connection units are purchased.

It is not advisable to combine it with convection circulation of the coolant. — when adding antifreeze to water, a problem is revealed due to poor mixing. Due to different densities, the coolant stratifies, preventing circulation — the upper part of the radiators does not warm up. The problem is eliminated by draining the water from the battery through Mayevsky crane and adding it through the expansion tank, achieving thorough mixing.

Insufficient efficiency of the saddle connection to maintain a comfortable temperature compensate by increasing the number of sections, that is, the area of the radiators.

Lateral or one-sided type

Universal, works well in both heating systems. Sometimes it is called one-way, since the "feed" and "return" pipes are connected to one side of the battery. The main condition is presence of bypass.

Photo 4. Side diagram of the heating batteries connection. The feed is in the upper right corner, the return is in the lower one.

Therefore, narrow radiators consisting of work effectively 5-6 sections, large-volume batteries with greater heat output due to the increased number of sections heat up unevenly.

Features of single-point connection

For a sleek look or when installing in tight spaces reduce the number of connections to the battery — this is a single-point connection. It is not advisable to install it in a private house, but if you still have to, then It is better to use a special knot. Its peculiarity is a special tube built into the radiator to distribute the supply and discharge of the coolant as far as possible. In private houses, where there is no one to complain to about the efficiency of heating, it is not recommended to make a single-point connection of radiators.

Useful video

Watch the video, which demonstrates the process of connecting a radiator to the heating system.

Optimal design is a guarantee of efficiency

It becomes clear that pipelines are difficult to harmoniously “fit” into the design of the premises. However, Heating efficiency directly depends on the type of heating system and the selected radiator connection scheme. In each specific project, different schemes will be optimal. It is important to create conditions in which the coolant flows easily through the pipelines and batteries, maximally and evenly heating the entire area of the radiators. Options must be selected to achieve a balance between the cost of manufacture and the convenience of further operation of the entire CO.