The most popular batteries - what are they? The device of aluminum heating radiators

The advantage of aluminum batteries over their analogues is that high heat output, low cost, variety of shapes.

These types of heating batteries are distinguished by their special design and internal structure.

How aluminum heating radiators work

According to the design, they are distinguished one-piece and sectional version. The first one is being made from profile plates, made using extrusion technology, which increases plasticity.

The resulting parts are welded together to create a complete battery. This makes it durable. The inner side is first coated with a polymer, which reduces the chance of leakage.

The sections are done in turns, then connecting. Pure metal is rarely used: aluminum is alloyed with silicon, zinc, sometimes titanium. These substances increase strength, reduce the risk of rupture and corrosion. Silicates are used as a sealant. Like solid ones, the inside of the device is covered with a special liquid to protect against high pressure.

Based on the manufacturing method, there are three types of aluminum radiators: cast, extruded and anodized. Among the technical characteristics, the following are important:

- The working pressure should be in the range 10-15 atm. In apartment buildings, the indicators are much higher, so it is not recommended to use aluminum devices in them. The test one is twice as large as usual, but it is better to have a reserve.

- The battery capacity is 82-212 watts, depending on the dimensions.

- The maximum heating of the coolant should not exceed 120 °C.

- Section weight — 1-1.5 kg. Volume - 0.25-0.46 liters.

- The center distance depends on the height and is in the range from 20 to 80 cm, sometimes exceeding it.

The parameters of each aluminum device may differ, but are always indicated. in the technical data sheet of the product.

Advantages aluminum radiators:

- Compactness and light weight make installation easier and do not require powerful fasteners.

- High heating speed, good heat transfer.

- Long service life, although less than that of cast iron.

- Short section length will allow you to choose the right one for a specific room. And also, by dividing the device into parts, you can make a system without excess heating.

- Aluminum is easy to process, which allows the creation of designer devices.

- Good protection against external damageThe radiator is very difficult to damage or break with physical impact, but quite easy to bend.

- The relative cheapness of the metal.

Among disadvantages distinguish:

- Poor corrosion resistance, which spoils the device during operation. Aluminum is an active substance that easily interacts with oxygen. Due to oxidation, the protective layer will be destroyed, since hydrogen gas is released during the reaction.

- The need to apply a polymer coating to prevent rupture, protect against discharge.

Sectional view of aluminum battery design

If you look at the device from above or below, you will see collectors. They create horizontal channels for transporting liquids. The bottommost one collects dirt, scale, and other solid particles, which helps to avoid clogging the entire device. A special valve is provided for removal.

Attention! The main disadvantage is frequent leaks at the joints.

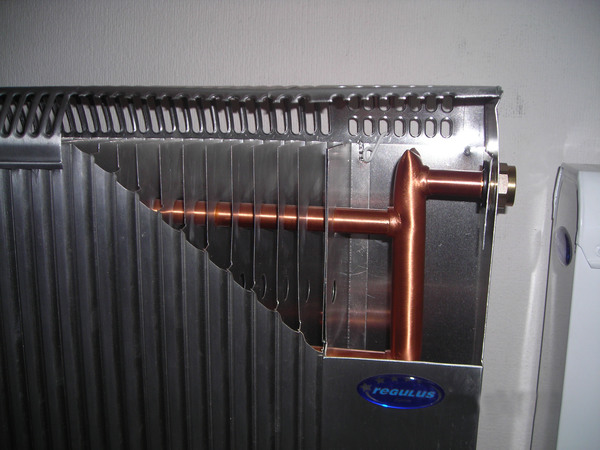

The sectional view of the aluminum radiator is shown in the picture.

Photo 1. Internal design of an aluminum heating radiator. The body is made of aluminum, and a copper tube runs inside.

Accessories for mounting the device

The quality of operation of the radiator depends on the parts that are sold together with it. The device comes with two important components: air release valve and fasteners. For apartment buildings, they are supplemented with a flow extension.

Mayevsky crane

Serves to remove air from the system. Helps to get rid of gas locks, overheated steam. Thus, it allows to reduce the pressure that has increased due to long-term operation of the boiler. Mandatory for installations in closed-type piping supplemented with a circulation pump.

Reference. It is desirable to have a valve for draining water. It will serve the same purpose as Mayevsky crane, affecting the liquid part.

Mounting brackets

Serve as radiator mounts. Must be included with the aluminum device.

Photo 2. Brackets for mounting aluminum radiators. The products are already mounted in the wall.

They are divided into three types:

- Corners for wood.

- Wall studs made from other materials.

- Anchors for any surfaces.

All threaded connections require plugs. Minimum diameter must be one inch (25.4 mm). They are also needed for nipples, but without size restrictions.

Sometimes aluminum radiators are wrapped with spacers with a heat-reflecting effect. They are placed along the wall, reducing energy loss into the atmosphere. The material used for manufacturing is foil or porilex. The substance is often supplemented with another layer of insulation, usually foam plastic.

Duct extender

The device is used to increase the thermal conductivity of the radiator. For this purpose, the latter must contain at least 10 sections.

Necessarily side connection to the main line, since aluminum devices transfer liquid diagonally. It is also important to have shut-off valves on both pipes.

If the conditions are met, for installation it is not necessary to change the current schemeOtherwise, it is recommended to invite a plumber.

Useful video

Watch the video to learn what to look for when choosing an aluminum battery.

Installation is a responsible task!

The quality of installation often depends on the components that the radiator is equipped with. Components have a great influence on the system, so it is important to install them correctly. To do this, It is recommended to invite a specialist.