Is it the best choice for heating systems? Features of the design of bimetallic heating radiators

Bimetallic radiators are stable occupy a leading position among heating systems. They left cast iron, aluminum and steel analogues far behind.

Manufacturers successfully combine all innovative technologies in these products, resulting in a light, compact, durable, and reliable heating element.

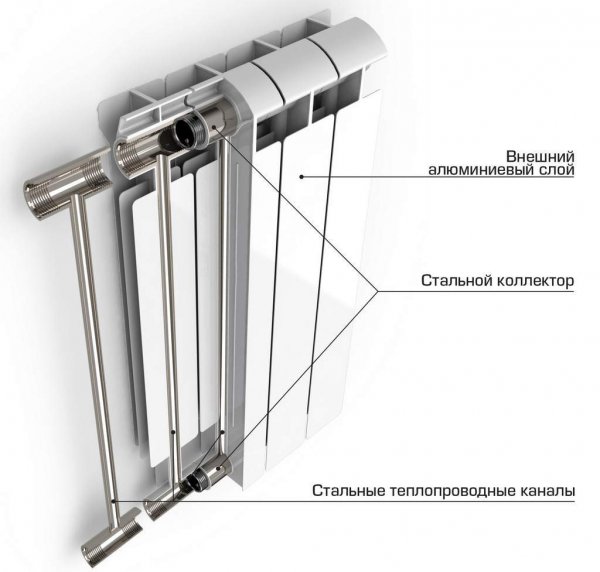

The basic idea of this device is in the use of two types of metal with different physical and structural properties. The body material has high heat transfer, and the metal of the internal frame is more resistant to corrosion and pressure drops that often occur in the heating system.

Construction of bimetallic heating radiators

The main difference of such batteries is their original internal structure. It is steel or copper frame, which placed in an aluminum shell. The frame consists of vertical and horizontal pipes connected by arc welding and filled with a coolant. This eliminates the possibility of the coolant coming into contact with aluminum parts. Radiator body has a special shape, allowing you to obtain the maximum amount of heat.

Photo 1. Schematic diagram of the bimetallic heating radiator. The arrows show the components of the structure.

The use of a steel frame in the construction is due to the following reasons:

- Steel does not react to pressure changes, periodically occurring in the heating system.

- For butt welded joints of the "steel-to-steel" type, it is typical high strength.

- Steel can contact with any coolant, it is practically not susceptible to chemical influences.

- Steel elements are not subject to corrosion.

Aluminum tooling bimetallic radiators quickly respond to temperature changes, thereby ensuring efficient heat transfer. Accordingly, a smaller amount of coolant is required than, for example, when using a cast iron radiator. This feature allows you to reduce the dimensions of the structure, make it more elegant, without reducing the heat flow.

Types of bimetallic radiators

All bimetallic batteries by design can be divided into two groups:

- sectional — made of steel frame and aluminum shell;

- whole - core made of copper coated with aluminum.

How sectional batteries are arranged

Each battery segment consists of a core, through which the coolant is transported.

The core is dall short steel pipes, connected by a vertical column of small diameter.

At the ends of the horizontal elements there is a special thread, with the help of which the sections are combined into a single structure.

Each core is housed in a specially designed aluminum shell. convection petal system for maximum heat transfer.

The advantage of sectional design — the ability to connect the required number of elements to obtain the required power.

Steel does not react to pressure drops in the heating system, is not subject to corrosion, and is resistant to the effects of chemical impurities found in heat carriers. Aluminum conducts heat perfectly, so sectional bimetallic radiators heats up the room very quickly.

Solid devices

In this design, instead of steel parts copper is used. Aluminum is used as a shell, which also serves as a heat exchanger. Copper the elements are soldered, so this battery cannot be disassembled. This is not entirely convenient, however, the cost of solid bimetallic radiators is much higher than sectional ones.

This is explained by the fact that copper has higher thermal conductivity and even less susceptible to corrosion, than steel. The inner surface of copper pipes is smoother, so there is no accumulation of carbonate deposits, therefore, the service life of such a device will be even longer.

Photo 2. Bimetallic heating battery of a solid type. The structure is fixed to the wall.

Features of finning

In order to maximize increase the heat transfer area of the battery, finning is used.

Heat transfer increases several times, due to the profiling of convection channels passing between the radiator fins, as well as the introduction of additional aluminum fins of a special configuration into the circuit. As a result, the heating area of the pipe increases several times, increasing the productivity of the device.

Attention! When selecting the size of the radiator, do not forget about technical standards: the device must be installed at a distance of at least 10 cm from the window sill and 6 cm from the floor.

Using engineering calculations backed up by practical methods, manufacturers were able to achieve the most efficient design for optimal air flow path. It is designed to capture cold air coming from the bottom of the device and evenly distribute the heated air flow obtained after flowing around hot surfaces.

Accessories: shut-off devices, fittings and others

Any batteries require additional elements that are used during installation or operation of the heating system. Bimetallic radiators are no exception.

Modern components are divided into three types:

- fasteners;

- shut-off valves;

- control devices.

Brackets can be floor or wall mounted, depending on where the radiator is installed. For each 3 sections Upper and lower brackets are provided. Floor mounts are rarely used.

Shut-off devices (plugs) serve to shut off the coolant flow if necessary. They are included with the radiator.

The task of control devices — determination of the optimal path for the coolant. These include a flow extender and a bypass.

Fitting are an important part of any communications network. This is a fastening component with a double-sided internal thread, which is used to fasten pipeline elements.

Useful video

Watch the video, which tells you what to look for when choosing a bimetallic heating radiator.

Conclusion

When choosing components, you need to remember that it's not worth saving on their quality, this can lead to a serious accident and failure of the entire heating system.

The advantages of bimetallic structures are their High heat dissipation, long service life, elegant appearance.

Comments