Easy installation and reliability - what else do you need? Features of using metal-plastic pipes for heating

Metal-plastic (MP) is called flexible pipes with three-layer wall: two layers of polymer and metal foil or mesh glued between them.

Due to their advantages, such pipes are actively replacing steel pipes in water supply, heating and sewerage distribution systems.

To assemble the pipeline correctly, It is necessary to understand the characteristics of pipes and be able to select fittings for them.

Content

- Description of metal-plastic pipes

- Technical characteristics: diameter, thickness, weight, service life and others

- Do-it-yourself installation of metal-plastic pipelines, what tools are needed

- Features of application for a private house

- Which pipes are better to use: metal-plastic or polypropylene

- Useful video

- Conclusion

- Comments (1 opinion)

Description of metal-plastic pipes

The polymer that covers the frame made of aluminum foil or mesh on both sides is most often used. cross-linked polyethylene (PEX). The term "cross-linked" implies the presence of cross-links between polymer molecules, which increases the strength of the material. And also used heat-resistant polyethylene (PERT).

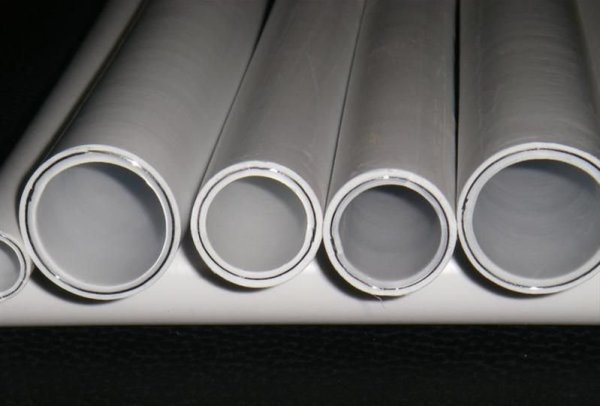

Photo 1. Metal-plastic pipes of different diameters in section. In the center of the products there is a frame made of aluminum foil.

Situated between layers of plastic The metal frame (reinforcement) performs the following functions:

- Provides high wall strength with relatively small thickness.

- Prevents pipe elongation when heated (polymers have a high coefficient of thermal expansion).

- Fixes the shape when bent (polyethylene without reinforcement tends to straighten out).

- Prevents air from diffusing through the wall (when reinforced with foil). This is important for heating system pipes: air entering inside promotes corrosion of metal parts of the pipeline and airing of the system.

The frame and polyethylene layers are bonded together using glue. MP pipes are produced in coils. length from 50 to 200 m. Pipeline parts or fittings - bends, shut-off valves, etc. - are made of brass.

According to the method of fixation, fittings are divided into:

- threaded: are detachable and can be used repeatedly, but require periodic tightening and therefore cannot be used for hidden installation of tubular products;

- press fittings: non-detachable, disposable, but do not require maintenance and therefore can be used for hidden installation;

- push fittings: the newest and still expensive variety, installed without tools, can be used for hidden installation.

Advantages and disadvantages

Advantages of the products:

- Small wall thickness and small dimensions of fittings.

- Light weight.

- Flexibility: allows you to bypass obstacles in one piece without using corners.

- The ability to retain shape when bent. This is especially true when installing "warm floors". Polyethylene pipes, unlike MP, have to be secured with clamps so that they do not straighten out.

- Gas impermeability of the wall.

- Durability.

- Low temperature resistance: refers to pipes not filled with water. When the water inside freezes, MP pipes, unlike polyethylene pipes, burst.

- Smoothness of the wall. Plastic is not only smooth in itself, but also does not tend to accumulate scale and other deposits. Therefore, the hydraulic resistance is lower than that of steel.

- Corrosion and chemical resistance. MP pipes do not require painting, are not damaged by rust from the inside (this explains their durability) and can be used for transporting chemically aggressive substances.

- Dielectric properties. There is no risk of electric shock, and there are no stray currents in the pipeline.

- Low cost.

- Easy to install. There is no need to use an electric welding machine or other complex and expensive equipment, only an affordable and easy-to-use tool.

- Ease of processing. The products are easy to cut and bend by hand.

- Possibility of installation of complete sections up to 200 m long.

- Low coefficient of thermal expansion (in comparison with polymers without reinforcement).

- High thermal resistance of the wall.

Flaws:

- Low strength and heat resistance compared to steel pipes. It is not permitted to use metal-plastic pipes in heating systems of apartment buildings, where the temperature of the coolant can reach +100°С and more (especially in the northern regions), and the pressure is 16 atm and more.

- High cost of fittings (compared to polypropylene).

- The appearance of fatigue damage after several bends.

- The inability to create from several sections of pipes and fittings by welding solid (monolithic) pipeline, as they do with polypropylene pipes.

Please note! Polyethylene is destroyed by the action of ultraviolet.

Technical characteristics: diameter, thickness, weight, service life and others

When choosing, the following parameters are evaluated:

- O.D: 16—75 mm. Products with a diameter of 16, 20, 26 mm.

- Wall thickness: from 2 mm (pipe diameter 16 mm), up to 5 mm (for diameter 75 mm).

- Reinforcing layer thickness: 0.19-0.3 mm (also depends on the diameter).

- Linear weight: 0.115 - 1.4 kg/m.p.

- Length of the bay: 50—200 m.

- Gas permeability: zero.

- Coefficient of thermal expansion: 0.026 mm/m*C.

- Thermal conductivity coefficient: 0.43 W/m*C.

- Roughness coefficient: 0.07.

Operating temperature range:

- maximum working (continuous): +95°>С;

- maximum short-term: +110°С;

- minimum: -39°С.

Working pressure:

- at temperature +25°С: 25 atm.;

- at temperature +95°С: 10 atm.

Breaking pressure: 80-94 atm. (at temperature +25°С).

Bend radius (minimum):

- when bending manually: 80-125 mm (depends on the outer diameter);

- on a pipe bender: 45—95 mm.

Service life:

- at temperature +20°С: 50 years;

- at a temperature of +95°C: 25 years.

Marking

A single-line alphanumeric code is applied to the product (indelible paint is used), displaying the following data:

- Manufacturing company.

- The standard that the pipe complies with (GOST, DIN etc.).

- Materials used: PE-R - polyethylene; PE-X - cross-linked polyethylene; PERT - heat-resistant polyethylene; Al - aluminum reinforcement.

- Stitching technology: A - peroxide; IN - by means of silane; WITH - electronic; D - nitrogen.

- Outside diameter and wall thickness. Type notation "20x2.5 mm". Sometimes measurements are given in inches.

- Maximum working pressure and temperature.

- Purpose (food/technical).

- Release date.

- Batch number.

Application, can the products be installed in heating systems

MP pipes are used:

- in housing and communal services: for the installation of heating, water supply, and sewerage systems;

- in industry: for laying gas pipelines, oil pipelines, process pipelines for supplying aggressive liquids and brines, compressed air supply systems;

- in the mining industry: in leaching of rare earth and alkali metals;

- for organizing hydro- and pneumatic transport.

Photo 2. Metal-plastic pipes installed in the heating system. Radiators are connected to the products.

The use of metal-plastic tubular products is excluded:

- if there are heat sources with temperatures above +150°C in the immediate vicinity;

- in heating systems of apartment buildings.

Attention! Indoors category "G" For fire safety reasons, the use of metal-plastic pipes is prohibited.

Do-it-yourself installation of metal-plastic pipelines, what tools are needed

To work you will need:

- pipe cutter: makes a smooth and burr-free cut perpendicular to the pipe axis - a condition for hermetically sealed fittings;

- calibrator: aligns the pipe to a perfectly round condition before installing the fitting;

- chamfer cutter: cuts the chamfer from the outside (the calibrator does this inside) for a tight contact with the fitting gasket;

- pipe bender;

Photo 3. Pipe bender for changing the shape of pipes. The device is also used for metal-plastic products.

- spring (maintains a round cross-section shape when manually bent);

- for installation of threaded fittings: spanners;

- for press fittings: Press pliers (they can be manual or electric).

The pipe is cut with some reserve necessary for installing the fitting. It is laid on clips (installed with a step of 1 m), screwed to the wall with screws or dowels.

Connection to steel pipes and radiators is carried out as follows:

- tow or other sealant is wound onto the steel pipe and a special fitting is screwed on;

- remove the nut with the split ring from the fitting and put them on the MP pipe;

- place the tubular product on the tail of the fitting and screw the nut onto the thread,until they hear 4 crackling sounds.

Features of application for a private house

The owner of a private house chooses the temperature mode of the heating system himself. It is advisable to install 80/60 mode (feed/return) instead of 90/70 - this will extend the service life of MP pipes. The mode is regulated by the boiler power and the circulation pump feed.

Which pipes are better to use: metal-plastic or polypropylene

Both products have almost identical characteristics. In turn, metal-plastic pipes not subject to thermal expansion, which is an undoubted plus.

But the installation of such products is much more complicated than polypropylene pipes. To make a heating system using metal-plastic pipes, It's better to trust a specialist.

Useful video

Watch the video, which explains how to properly connect metal-plastic pipes.

Conclusion

Metal-plastic pipes have an impressive list of advantages. Each of its points is confirmed by the practical experience of users who successfully use this product not only in water supply systems, but also in heating systems.

Comments

A significant advantage of metal-plastic pipes is their low coefficient of thermal expansion (that is, there is no deformation, bending, or deflection), unlike pipes made of polypropylene.