Not only the quality of heating equipment is important, but also the diameter of pipes for heating a private house

From the correctly calculated pipe diameter depends on the heat and heating costs of the house.

An adequately selected option will not require additional costs for heating the liquid and will allow the coolant to pass through the system at a good speed.

Content

What diameter of pipes is needed for heating a private house

Technical characteristics of the pipe include: three types of diameters:

- external — diameter taking into account the wall thickness, taken into account when calculating mounting fasteners, required area, thermal insulation, etc.;

- interior — the leading technical parameter of the element, shows the size of the clearance, calculated for the system’s throughput capacity taking into account the physical qualities of the coolant;

- conditional — the average value of the internal clearance, rounded up or down to the millimeters or inches of the standard value, is approximately equal to the internal diameter, and is marked as DN (previously DU).

Reference. The nominal bore is calculated to determine the throughput capacity of the pipeline.

When selecting the required section, the following parameters are taken into account:

- hydrodynamics systems - with an increase in the volume of the passing coolant, the efficiency of the system decreases, therefore, choosing a larger pipe diameter entails a decrease in the efficiency of the system;

- pressure inside systems - if the cross-section is large, then the speed of the coolant flow through the circuit is low. This increases heat loss, the risk of boiling liquid in the heating boiler during natural circulation.

Attention! If the pipes have a smaller diameter, then this is also leads to a loss of fluid velocity, since the resistance inside the system increases and the coolant does not pass. This fraught with loss of temperature and noise during operation batteries.

- heating boiler power — the stronger the boiler, the larger the diameter that can be used;

- extent of the system - affects the circuit's throughput capacity, for example, a pipe in 25 millimeters may skip about thirty liters of water per minute;

- method of liquid circulation — for forced circulation it is permissible to take a smaller cross-section compared to natural circulation;

- coolant cooling rate — a correctly selected diameter will ensure adequate speed of passage of the coolant throughout all rooms;

- area of the premises — the cross-section is one of the heat transfer parameters per square meter;

- Number of wiring and turns — reduces the speed of the coolant and the pressure in the system;

- material — the influence of the physical characteristics of the material on the throughput capacity of the coolant and heat transfer at a certain speed of movement of the energy carrier.

Power calculation

First of all, the capacity of the entire heating system is calculated. The calculation is made according to the formula:

Qt= V*∆t*K/860

In which:

- Qt — heating power, kW.

- V — the size of the heated room, m³.

- ∆t — the difference between the temperature inside the home and the temperature outside the home in winter.

- TO — a coefficient showing the heat loss of a building.

For standard buildings, average values are used.

Calculation principle

The general starting point for determining the required cross-section is the area of the heated room - 10 sq. m. require 1 kW of heat, so the room is in 30 sq. m.

with a ceiling height of about three meters it should receive 3 kW.

Next, determine the optimal speed of passage of liquid in the system - not less than 0.2 m/s and nothing more 1.5 m/s.

Having this data, the diameter is calculated using the formula:

D= √(354*(0.86*Q/∆t)/V),

Where:

V — the speed of the coolant in the system (meters per second);

Q — the required volume of heat for heating (kW);

∆t — the difference between feeds (reverse and forward) (C);

D — cross-section (in millimeters).

Determining the correct pipe size for heating systems

The size of the pipes depends on the type of heating system of a private house.

With natural circulation

The first and last pipes that are installed with the heating boiler must correspond to the diameter of its branch pipe. from 25 to 50 mm.

Photo 1. Diagram of a heating system with natural circulation. The numbers indicate the components of the structure.

It is advisable to choose the maximum permissible diameter, since it will be reduced in the future to increase the pressure in the system (branching with a cross-section of an inch is performed with a pipe in 3/4 inch, the next part is half inch).

Reference. The first reduction is made after the first branching. At the end point, the minimum diameter corresponds to the recommended (12.7 or 19 mm).

With forced circulation

For systems with forced circulation it is acceptable to take narrower pipes, than for gravity-flow, since the pressure in the system is provided by a pump.

Section depends on the connection diagram and the wiring and changes in the system from less to more and vice versa or it remains unchanged (for a one-pipe heating system).

With radial distribution cross-section of the pipe going from the boiler to the collector ― 19 mm, the branch goes to the radiators through pipes 12.7 mm.

Types of radiators

The following batteries are used to heat rooms:

- cast iron - durable, insensitive to coolant and pressure, capable of withstanding water hammer;

- aluminum - average service life 15 years old, good heat transfer, quite fragile, cannot withstand high pressure and dirty coolant;

- bimetallic - serve 25 years old, give off heat well, are resistant to water hammer, and are insensitive to energy sources;

- steel - are operated for 10 years, good heat transfer, withstand medium pressure, are capricious to the coolant;

- copper - durable, insensitive to the type and quality of liquid, withstand pressure and its changes well.

Connection

Two popular types battery connections:

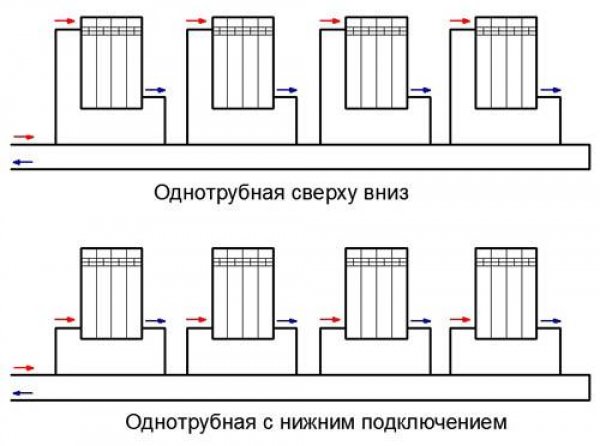

- single pipe — both the supply of hot coolant and the return of cooled coolant occur through one pipe;

Photo 2. Single-pipe diagram of radiator connection based on the principle of top-down (top) and bottom type (bottom).

- two-pipe — the heated liquid is supplied through one pipe, and the cold liquid through the second.

Reference. The third type is not the most popular. collector type, in which pipes go from one manifold to each radiator. The method is good for heating, but expensive in terms of equipment cost.

In each type the contour can go:

- vertically — from the upper floors to the lower ones, often used in gravity systems;

- horizontally — the pipe connects all radiators in series and is used in both natural and forced circulation.

Radiators can be connected from the top, bottom, or diagonally. The type of connection affects the diameter of the connected pipes and their number.

Types of pipes for heating

Various types of pipes are used for heating systems.

Metallic

The most popular type produced from two types of steel:

- carbon:

- little susceptible to expansion;

- low price;

- insensitive to mechanical influences;

- highly susceptible to corrosion.

- stainless:

- not subject to mechanical influences;

- less susceptible to corrosion;

- slight expansion;

- higher price compared to carbon.

Metal pipes are manufactured:

- welding (seam) - seams can be straight or spiral; in heating systems, circuits with a spiral seam are used, since a straight one can diverge under the influence of temperature;

- rolling — in terms of technical characteristics and durability, they are superior to sutured ones (not sensitive to temperature and pressure), but more expensive.

Positive properties include:

- slight expansion;

- Possibility of installation on any surface except plasterboard;

- resistance to water hammer;

- temperature limit up to 1500 degrees.

Of the shortcomings we will only note:

- susceptibility to corrosion;

- inconvenient installation;

- big weight.

Important! Regardless of what pipes the system is equipped with, it is recommended to install the first links of the branch and return from the heating boiler only metal parts.

Copper

The most expensive, but also exceptional in quality. Produced from:

- high quality copper;

- mixtures of copper and zinc;

- copper coated with a layer of polyvinyl chloride or polyethylene.

Reference. For heating systems, you need to choose pipes with markings EN 1057, which refers to the treatment of copper with phosphorus, which further increases its resistance to water.

According to the manufacturing method, pipes are divided into:

- annealed - more elastic and soft;

- not annealed - tough.

During installation they are connected by hard soldering.

The advantages include:

- wide temperature range (from -100 °C to +250 °C);

- slight expansion;

- service life up to one hundred years;

- environmentally friendly material;

- resistance to high pressure.

Photo 3. Copper pipes connected to heating radiators. Such constructions serve for a very long time.

The disadvantages include:

- it is undesirable to use copper with other metals - chemical reactions that occur during interaction can lead to corrosion;

- Stray currents have a negative impact on service life.

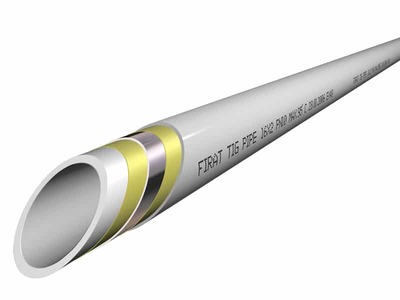

Metal-plastic

Metal-polymer (metal-plastic) pipes — five-layer construction: cross-linked (modified) polyethylene, adhesive layer, thin aluminum, adhesive and protective layer of polyethylene inside. The tube is stitched with an overlap (ultrasonic) or a butt seam (laser).

Metal-propylene contours are used in:

- water supply and heating;

- transmission of liquefied gases;

- supply of hot air;

- as a protective screen for cables.

Photo 4. Metal-plastic pipes for heating systems. There is a layer of aluminum in the middle part of the products.

The use is due to the large number of advantages of this type:

- resistant to aggressive environments;

- resistant to corrosion;

- economical to install;

- there are practically no leaks;

- do not overgrow;

- do not require welding with press fittings;

- impermeable to gases;

- resistant to biodeposition and rust;

- flexible, holds shape well;

- low thermal conductivity;

- withstand thermal loads up to +110 degrees;

- not prone to condensation;

- ease.

The disadvantages include:

- by linear expansion 2.5 times exceed metal pipes;

- subject to mechanical influences;

- with prolonged exposure to sunlight and electromagnetic fields they wear out quickly;

- break if installed incorrectly or if the bending angle is exceeded;

- weak against organic acids;

- The crimp connections need to be tightened.

Pipes are used for heating installation in 16 and 20 millimeters.

Important! When installing the system, expansion is taken into account ― the diameter should be a third smaller, than similar steel ones.

Useful video

Watch the video, which explains how to correctly calculate the diameter of pipes for a heating system.

Attention to detail

There are no insignificant details in a heating system. Pay close attention to the ingredients: pipe diameter, material, manufacturing and installation method - and you will achieve warmth in your home and trouble-free operation of the main line elements.