Types of metal pipes for heating: pros and cons. Installation methods

Pipes for the heating system are made from two types of material - metal or plastic.

Their diversity is great and each type is used in specific conditions and premises.

Content

Advantages of metal and metal-polymer pipes for water heating of a house

Any material will do to create the inner contour, but we need to focus on the climateFor example, in cold areas where sudden temperature changes are possible, metal has superior characteristics to plastic.

This is due to the fact that synthetic material may not to withstand a sudden cold snap.

This factor is the main advantage of metal over plastic. In addition, it is worth highlighting advantages of metal pipes:

- Mechanical strength.

- Durability subject to operating instructions.

- Possibility of replacing the damaged area.

- Wide temperature range, which can withstand the material.

- Increased resistance to system pressure.

- Protection against mechanical damage.

- Possibility of giving the required shape.

- High thermal conductivity.

- Possibility of self-installation if equipment is available.

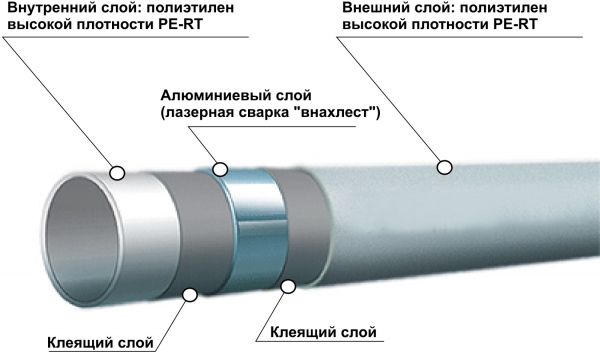

Photo 1. Metal-polymer pipes, consisting of several components, combine the advantages of both metal and plastic.

Types of pipes

The pipes are divided by two criteria: material and method of creation.

Attention! The variety of metals used to make heating pipes allows you to choose the right one material under certain criteria. The method of creation also influences the application of products in specific conditions.

Regardless of the installation location, an experienced builder will select a material that meets all requirements.

Steel black metal

Compared to stainless steel, black steel subject to corrosion, serves less, and besides, it is required clean periodically. A small advantage over stainless steel is the type of installation: both threaded and welded will do. Black steel is cheaper, but additional costs for sealant will be required.

Stainless steel

The golden mean. It has a long service life, is protected from corrosion, holds high temperatures and is resistant to pressure. Stainless steel pipe can take any form required by the customer, for this it is enough to use a welding machine.

Photo 2. Stainless steel pipes with a long service life are not subject to corrosion and retain temperature well.

Galvanized steel

Its properties are similar to those of stainless steel, but it has a longer service life, although over time begins to suffer from rust. When installing, it requires additional elements made of the same material. When installing galvanized pipes, it is necessary to observe safety precautions.

Solid drawn and welded

Solid drawn pipes are metal pipes obtained by material rolling.

Welded ones are made of metal by weldingThe sheet of material is folded and boil on both sides. Before the end of production, the seams are checked with a device that detects defects. They have a similar warranty period to solid-drawn products, but are cheaper.

Copper

Non-ferrous metal pipes are made hardened or welded. In the first case, the mechanical strength, in the second it increases flexibility. Installation requires silver soldering, for which you will have to invite a specialist. Copper is considered the most durable, which is due to its cost.

Photo 3. Copper pipes for water heating in the house are distinguished by high strength, durability and high cost.

Choice

When choosing, you need to focus on the following indicators:

- Type of heating.

- Maximum permissible temperature conditions, resistance to pressure in the system.

- Installation type and configuration.

- The heat carrier used.

- Budget.

Service life

The warranty period is specified by the manufacturer. To maintain the system in good condition, it is necessary its correct operation. You should think about the service life in advance, before purchasing: calculate the system pressure, determine the required pipe thickness, and select the material.

Reference! High-quality metal products can last a long time more than 25 years.

Installation

Installation of metal pipes is carried out according to general principles, regardless of type:

- When changing the harness, products of similar thickness should be used. When the cross-section diameter decreases, the system pressure decreases, which leads to a decrease in operating efficiency.

If this rule is violated in an apartment building, you can expect the arrival of representatives of the housing and communal services sector. The employees are obliged to restore the configuration of the engineering system at the expense of the apartment owner.

- When installing ball valves or throttles, it is necessary to take into account the bypass before the shut-off valves. If the initial configuration is violated, the owner will face the consequences described in the previous paragraph.

- Radiators should be changed after the pipes. Products with 10 sections and more are connected vertically, so that each section warms up.

- If the radiator is equipped with a bottom connection, An air vent or a Mayevsky valve should be installed in the upper plug. A similar device is mounted at the highest point of the pipe system.

Important! Air vent not needed in apartments in which straight pipe goes up.

Types of thermal insulation

Thermal insulation is installed on the pipes running across territory exposed to the cold, for example, on the street.

Regardless of the material, the devices freeze, which can completely deprive the heating.

Insulation serves to keep pipes warm, as well as for sound insulation.

Various materials, differing in price and composition, are used as heat insulators.

Mineral wool

Mineral wool is most often used for heating pipes. The properties of the substance allow it to be used in any conditions. Mineral wool holds high temperatures, durable, versatile, while having a low price. Together, these factors make the substance one of the best for thermal insulation.

Polyurethane foam

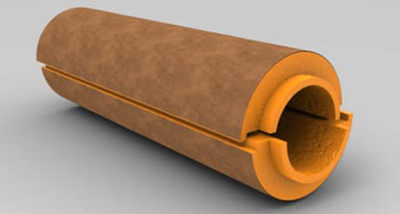

The material is of synthetic origin. Thermal insulation is performed in the form of halves of a pipe.

The assembly is carried out accordingly: the harness is “dressed” in insulating material, which is then fastened.

Polyurethane foam helps protection from low temperatures, increases mechanical strength, some of its types reduce the possibility of leakage.

Synthetics

In addition to polyurethane foam, other materials are also used as thermal insulators: 4 substances:

- Foamed rubber. In addition to its direct function, it also has fire protection. The versatility of the material allows for insulating a system containing frequent bends.

- Foamed polyethylene is similar in function to rubber, and in installation to polyurethane foam. This substance is suitable for insulation inside buildings. Polyethylene is thin and interacts normally with any building materials.

- Foam plastic is similar to polyethylene, but has greater mechanical strength. Thermal insulation is also made in the form of pipes that "wrap" the heating elements. It is also worth noting the service life: foam plastic is durable and can perform its function several decades.

- Foam glass has better performance characteristics compared to other synthetic materials. The substance is resistant to leaks, conducts almost no heat, and has high mechanical strength. The low prevalence of foam glass is due to the high price of this material.

Photo 4. Thermal insulation of a plastic pipe with foam plastic, which can serve for several decades.

Liquid

It can be made simpler than any other type. It is enough treat the heating system with paint, applying a thin layer. When the liquid dries, the pipe is considered thermally insulated and stops releasing heat.

How to make thermal insulation

Installation of thermal insulation is carried out in several steps:

- First of all, the material is calculated and purchased.

- The heating pipe is wrapped in foil.

- Thermal insulation is being installed. The pipes are literally covered with hard materials, and wrapped with soft ones, securing them with improvised means.

- The installed thermal insulation is secured. Hard in parts, as it is installed, and soft - exclusively as a whole.

- At the end of the process a check is carried out for the presence of missed sections. The identified vulnerability is being fixed.

- After installation is complete the thermal insulation is being re-fastened.

- If necessary, a protective layer is applied on top.

Useful video

A video review that provides instructions for installing steel heating pipes.

General recommendations

When choosing a material, you need to focus on climate conditions and your budget. Non-ferrous metals are better than ferrous ones, although they have less mechanical strength.

Definitely in the apartment diameter is taken into account heating pipes. For complete piping in a private house, the size is selected based on the calculations made.

Comments

The pipes are light in weight and can be easily attached to any wall.