Installing copper pipes for heating: all the pros and cons of such a system

Copper pipes used in the heating system are long hollow products that are different high level of heat transfer, considerable strength and comparative durability.

There are a large number of these types of pipelines, the installation of which can be carried out at home even with your own hands without the help of specialists.

Advantages and disadvantages of copper pipes for heating

Only copper is used to make copper pipes. high quality copper. In some cases, alloys of this material with zinc are used. Most often, the products are covered with a polyethylene layer on top or decorated with PVC. This is a significant improves their appearance, reducing thermal energy losses.

Main advantages copper pipes:

- long term exploitation;

- small weight;

- endurance as low, and high temperatures;

- absence the need to carry out additional exterior finishing;

- possibility of use after a freeze-thaw cycle;

- smooth inner surface, preventing the accumulation of limescale deposits;

- small coefficient of thermal expansion;

- high level oxidation stability etc.

Like any other pipelines, copper products have a number of disadvantages, which are worth paying attention to before buying:

- complete incompatibility with other materials;

- high price;

- softness and plastic, which have an adverse effect on systems where there are solid particles in the coolant;

- necessity insulation from stray currents;

- complexity installation;

- necessity careful exploitation.

Some of the listed advantages and disadvantages can be perceived in two ways.

This concerns plasticity and high thermal conductivity. Softness, for example, allows easy to bend pipes, but they need to be fix over very short distances.

As for high thermal conductivity, it is a positive factor only when open layout, in this case, heating occurs very effectively.

Types of Copper Tubes

Currently, there are several different types of copper pipes. Each of them has its own operating and use features. Classify products according to 5 characteristics:

- By composition of the materialSometimes pure copper is used, but in most cases it is made from alloys, adding zinc or tin. At present, the composition of copper pipes is regulated in accordance with GOST 859 And GOST 15527.

- By manufacturing methodCopper pipes can be drawn cold woven or drawn out from a welded blankIn the first case, the products are marked index "D", and in the second - index "C".

- By availability seamThose variants that do not have it are called seamlessIf seams are present, then the pipes are made from a welded blank.

- By wall thicknessCopper pipes can be either thin-walled, and thick-walledIn the first case, the wall thickness is within from 0.2 to 0.7 millimeters, and in the second - from 0.8 to 1 mm. Thin-walled pipes are most often not used for heating systems, unlike thick-walled ones. At the same time, in residential buildings, those products are mainly used in which the wall thickness reaches even up to 1.5 millimeters.

- By presence or absence protection. Pipes can be unprotected or insulated. In the second case, plastic materials are used, such as PVC And polyethyleneTheir role is to prevent mechanical damage.

Popular manufacturers

The main countries where copper pipes are produced are: Germany, USA, Russia, China and Ukraine. The most popular brands:

- KME;

- Majdanpek;

- Frigotec;

- Mueller;

- Hailiang;

- Wieland;

- "ARLAN-MET"

- "Artemovsky Metal Processing Plant";

- "TRUST-Contract".

The cost of copper pipes depends on several factors, among which the most important are the diameter, place of production, type of manufacture, composition. Products with diameter 6 mm can be purchased for 117-142 rubles per 1 meter. If the clearance size reaches 22 millimeters, the price goes up up to 409-484 rubles per 1 meter.

Do-it-yourself installation of the system

Installation of copper pipes is a process that can be carried out in different ways. There are several options for connecting such products, which include assembly, welding and soldering. It is permitted to use fittings from other manufacturers, which can in certain cases reduce financial costs.

Counting fittings

In order to install copper pipelines, fittings are required. They can be either crimping, or solderingIn the first case the connection will be detachable, in the second - non-detachable.

Selection of fittings will also affect the fastening of all elements.

Their number directly depends on the selected equipment and the heating system scheme, as well as on the type of purchased products. The length of the latter can be from 50 centimeters to 25 meters.

Assembly

After calculating the required number of fittings, the assembly of pipes begins. To begin, the edges of the products are covered with a thin layer of flux. The procedure is necessary to prevent the oxidation process, which inevitably occurs when the elements are heated. This method of treatment prevents foreign substances from settling on the joint, which negatively affect the strength.

Compressed fittings ends pipes using special pliers are clampedIt is this pressure that carries out the fixation.

Welding

This method of connecting copper pipes is used only in certain cases.

This applies to situations where products are used whose wall thickness reaches 1.6 millimeters, and their diameter exceeds 110 mm.

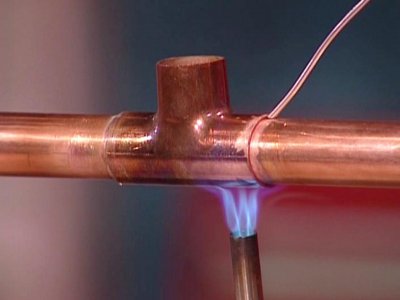

Soldering

Most often, soldering of copper pipes is used in cases where the products are hidden in the floor or wall.

The basis of soldering is capillary effect. It is this that influences the uniform distribution of solder across the pipe cross-section.

The main feature of such a connection is the use of fittings, the diameter of which is slightly larger than the diameter of the products. This is necessary to create a gap from 0.1 to 0.15 millimeters.

There is low-temperature and high-temperature soldering of copper pipes. In case of DIY installation, only the first method is used. It is used for pipes whose diameter is within from 7 to 110 millimeters, and the thickness of the walls does not exceed 1.6 mmThe operating temperature of the joining process in this case is 110 degrees Celsius.

Can I use varnish for coating?

Over time, after long-term contact of copper with air, a process of its oxidationAs a result, the products lose their reddish hue, becoming greenTo prevent such changes, varnish is used. This is the substance that copper pipes are coated with.

The varnishing process it happens as follows:

- First you need to wipe copper pipes using 10% alcohol solution of hydrochloric acidAfter applying it, the parts must be polish cloth until shiny. After this, the pipes should be washed with clean water.

- After the alcohol solution has completely dried, you need to use two-component acrylic varnish, which is also used for painting cars. It does not change the shade of the pipes. Depending on the type of varnish chosen, its dilution can be carried out in a ratio of 2:1 or 3:1. In addition, the following is added: 10-15 percent solvent.

Photo 1. Two-component acrylic varnish of the Vika brand, complete with a hardener, weight - 1.28 kg, suitable for coating copper pipes.

Drying acrylic varnishes pretty fastIf a solvent that is an inhibitor is used, this process may be delayed.

Important! Experts note that alkyd varnishes are not used for processing copper pipes. This is due to the fact that they can interact with copper particles, forming green layers.

As for one-component acrylic varnishes, they should be used only in interior spaces. This is due to the fact that such substances have low durability. The same applies to special combined nitro varnishes.

To ensure maximum quality and efficiency, application should be carried out at least 3 times. In this case, between each subsequent layer it is necessary to wait until the previous one is completely dry.

Useful video

Check out this video that shows you how to properly work with copper pipes yourself.

Conclusion

Thanks to all its positive qualities such as sustainability to temperature changes, corrosion processes and oxidation, period of service copper pipes can reach 100 years. That is why copper pipes are currently are extremely popular.

Comments