No opportunity to buy equipment? You can make a heat exchanger for heating a private house with your own hands

Accommodation in a private house in autumn-winter period impossible without a heating system. Only it creates a favorable microclimate in the room.

The heat exchanger plays an important role in its design. You can't do without it in a private house. Thanks to the device, heat is supplied even to remote rooms. There is several types of this device, each of which has its strengths and weaknesses.

Content

What is a heat exchanger for heating a private house?

A heat exchanger is a device that transfers heat from the generator to the coolantIn private homes, surface devices are usually used. Thanks to such heat exchangers, heat is transferred directly through the walls of the unit.

Installation in the boiler

The device gives maximum efficiency in gas, electric and other boilers, operating on solid fuel. Inside the heating device, they install serpentine pipesWhen the fuel starts to burn in the boiler, the device heats up. Due to this, the coolant circulates throughout the system, transferring heat into the room, and comes back to the coil.

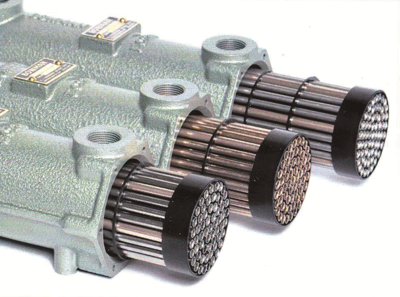

Photo 1. Steel flow-through heat exchanger for the Vitopend 100 boiler, manufacturer - "Viessmann".

If the main heating device used in the house is not a boiler, but bake, then the use of a heat exchanger is also relevant if the building has a large area. The stove does not heat the cottage due to its low power. For this reason, a coilIt heats the coolant to a high temperature, and this heat is distributed throughout the house through radiators.

Types depending on the material

Depending on the material of manufacture, there are cast iron and steel devices. They have their own advantages and disadvantages.

Cast iron

The main advantage of devices made of cast iron is long service life.

The material does not corrode when in contact with water, so the device lasts for a long time.

The disadvantage of cast iron product is increased requirements for gas equipment. This is because the area between the warm and very hot part of the device is a vulnerable area where cracks often form in the metal.

Helps prevent defects from occurring flushing device. This procedure removes deposits in vulnerable areas of the heat exchanger.

There is a place inside the appliance where warm water meets cold water, i.e. the area where the coolant returns to the heat exchanger from the heating system. This is the risk zone for the occurrence of low temperature corrosionTo reduce the possibility of rust, a three-way mixing valve is installed on the return line of the device.

Steel

Such heat exchangers are the most common. This is explained by the simplicity of material processing and their affordable price. Steel products are especially popular in domestic heating devices.

Main qualities of the material:

- Increased strength. This protects the heat exchanger from mechanical damage.

- PlasticThis property prevents cracks from appearing on the device when heated.

Flaws:

- Tendency to the formation of rust. Corrosion occurs inside and outside the device. This reduces the service life of the device.

- Heat exchanger made of steel increases fuel consumption. This is due to the thickening of the device walls and the increase in the dimensions of the coil during the manufacture of the device. Manufacturers are forced to perform such manipulations to increase inertia.

Varieties by design

Depending on their location, heat exchangers can be internal or external.

External

It is located near chimney. This is a container that "surrounds" the chimney. The heating of the coolant occurs due to the heat that the products release during combustion.

A section of the pipe that removes combustion products is placed inside the container. Behind such heat exchangers easier to care forThey are easy to dismantle for descaling and defect elimination.

Internal

This is a container located inside the oven, directly above the firebox. The device is easy to install, but if there is a need to descale the device or eliminate defects, problems will arise.

Installation in a brick oven

A heat exchanger is installed in the furnace for increasing heat transfer heating device.

If the furnace does not have a heat exchanger, the coolant is distributed unevenlyBecause of this, the air temperature will be high near the heat source, and low in remote places.

If you connect radiators to the stove and pour water into such a system, the operation of the device will be comparable to the operation solid fuel boiler. Here, water, walls and flue channels are also heated. When the stove is fired, the heat carrier moves from the coil to the batteries, and after the fire stops, it takes energy from the heated walls.

Reference! The heat exchanger reduces the useful area of the firebox. This leads to the need monitor fuel combustion and add fuel more oftenThe correct arrangement of the water circuit and its relation to the dimensions of the firebox is the solution to the problem.

Advantages

Advantages:

- Heat exchanger easy to manufacture and install with your own hands.

- The warmth in the room is provided the furnace itself and the coolant, distributed among batteries.

- The device operates from any type of solid fuel.

- Attractive appearance.

Rules for DIY manufacturing and installation

Despite the large selection of factory models in specialized stores, users prefer to make devices with their own hands.

This is not surprising, because independent production allows to take into account the dimensions the furnace where the product is installed and the volume of the firebox.

The device is made of tubes through which liquid moves. The disadvantage of the design is the possibility of boiling liquid during intensive heating. To prevent this from happening, professionals advise using large-volume pipes.

Water also boils due to weak movement. This problem occurs due to incorrect installation. To prevent it from appearing, a pumping station is installed. The unit makes the water circulate intensively, which prevents it from stagnation.

Brick oven devices are made of metal 2.5 mm thick. The basis of the device is two containers: the upper one in the form of a cylinder and the lower one in the form of a rectangle. The pipes connect both tanks. The diameter of the pipes depends on the size of the firebox and the area of the room. The gap between the pipes should be minimal. All components are connected to each other by welding.

Installation procedure:

- understands part of the brickwork;

- into the firebox on a pre-prepared foundation the device is fixed;

- is being carried out brick laying, in which two holes are left for the construction pipes;

- when the masonry is ready, the device connected to the heating system.

Important! After welding, installation and filling with water, it is checked strength device. For this purpose, the structure is filled with compressed air. The pressure is controlled by a pressure gauge.

If the seams do not leak, the device ready for use. If water leaks between the seams during testing, the water is drained and used. sealant.

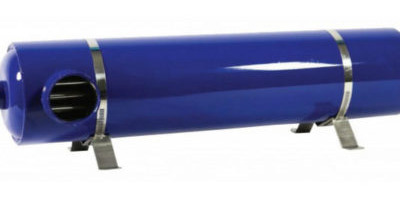

Features of use on a chimney pipe

The heat exchanger is also fixed to the chimney pipe so that some of the heat did not leave the system with the smoke, and was used to heat the coolant.

Such devices are used in small stoves in baths or summer cottages.

The heat exchanger on the chimney is not capable of heating a large room, but it the power is enough for a couple of batteries. The device is installed not only for heating, but also for heating water.

The structure is made from a large-sized pipe with a diameter of 500—700 mm. A tank made of made of stainless steel. A vertical pipe is fixed in the center of the device, the diameter of which corresponds to the size of the chimney, and two branches are attached at the bottom and top using welding.

Attention! Since the heat exchanger takes away the heat from the combustion products, they cool down quickly at the outlet. This leads to reducing the draft in the chimney and slowing down the combustion of fuel.

Sauna stove with heat exchanger

A heat exchanger for heating is installed not only in residential premises, but also in baths. Such a device has its own characteristics:

- the device serves simultaneously for heating and for heating the coolant;

- the device can be placed directly in the steam room itself, in the changing room or in the washroom;

- device easy to install even by a non-professional master;

- heat exchanger heats water quickly;

- the device is used in different baths;

- the device has long shelf life.

General installation recommendations

Compliance with the rules of manufacture and installation guarantees reliable and long-term operation of the heating system and will help to avoid many problems:

- supporting contours of the device are not fixed to the walls with fixed connections;

- It is recommended in the design use copper pipes, since this material is plastic and has good thermal conductivity;

- pipeline cross-section — not less than an inch.

Useful video

Check out the video to learn how to make your own heat exchanger.

Disadvantages of homemade devices

Homemade heat exchangers for the furnace have disadvantages:

- device reduces heat retention time ovens;

- absence automatic water heating control;

- if no one lives in the house during the winter, then the water in the pipes will freeze, and the entire heating system will fail.

If the heat exchanger is made correctly and installed into the heating system, the house will always be warm, and the device will last for decades.

Comments