A laboratory muffle furnace can help you harden metal and grow a crystal

A laboratory muffle furnace is a special type of furnace high temperature heating equipment, intended for use in laboratory conditions. This device is a furnace with a special design.

It provides for complete lack of interaction heated objects with various components released into the air as a result of fuel combustion (soot, gaseous substances, and carbon black).

To create such heating conditions, the following is used: muffle – a fireproof chamber, which is a kind of barrier between the heated product and the fuel used.

What is a laboratory muffle furnace?

Most of these muffles are made of fireproof brick, heat-resistant steel or high strength ceramic fiberIt is due to this device that manufacturers have the opportunity to prevent contamination of various expensive metals, as well as chemically pure samples, with foreign substances.

Due to the fact that the equipment has special technical characteristics, it Suitable for use in many areas industry:

- V chemical laboratories;

- at enterprises engaged in production jewelry;

- V geophysical laboratories;

- at enterprises that manufacture wax objects;

- V food industry;

- at enterprises performing cupellation of various precious metals;

- V dental centers;

- to perform various analytical works (heating and drying, burning or growing crystals);

- For firing of various shapes for casting;

- for manufacturing porcelain or ceramic products;

- For swimming trunks, and also hardening of various metals and their alloys;

- for carrying out cremations.

Modern equipment must necessarily have the following characteristics:

- Sufficient interior space so that the items being processed fit freely inside the device.

- Wide temperature range, allowing you to perform different types of work.

- Thermoregulator.

- System hoods.

- Opportunity connections to a computer (requirement applies to some models of devices).

Design Features

The equipment has a special design, which is adapted to create special conditions for processing various products. The main difference from other types of furnaces is the presence refractory chamber or the so-called muffle. This creates a barrier that prevents the interaction of the surface of the materials with the gaseous substances released from the fuel used.

For the production of a muffle — the main part of the device — and other elements, manufacturers usually use heat-resistant steel, firebrick, and ceramic fiber, which has high strength.

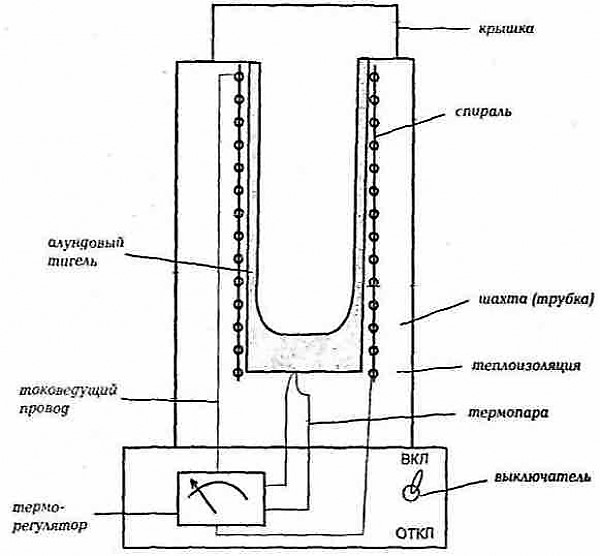

Photo 1. Schematic representation of the laboratory muffle furnace. Only the main parts are indicated.

How to choose the right device?

To ensure the most efficient operation of the equipment, you need to pay attention to the following: characteristics:

- parameters;

- maximum possible loads;

- power;

- maximum firing temperature;

- working voltage;

- supply voltage;

- uniformity of heating;

- safety of equipment operation;

- price.

First of all, you need to decide volume working chamber, as well as with temperature range. In addition, it is imperative to pay attention to heating complexity.

Types of laboratory furnaces

No less important indicators when choosing equipment are speed and uniformity of heating muffle chamber.

Depending on individual requirements, you can choose horizontal or vertical oven: the first one has a fairly large capacity, and the second one heats up in a short period of time.

Laboratory muffle furnaces are equipped with open or closed heating elements. Devices of the first type are ideal for use in conditions where it is necessary to warm up the chamber. to a high temperature in a short timeHowever, such equipment is more susceptible to the negative impact of various aggressive substances released during the processing of objects.

Furnaces that use a closed heating element are distinguished by longer service life, uniform heating working chamber, but it takes much longer to heat up to maximum. A significant disadvantage of this type of device is that if the heating element breaks, the entire chamber will have to be replaced.

The simplest design is that of equipment that has single stage thermostat. Its main peculiarity — the chamber is heated to a certain temperature from the start and then maintained throughout the work process. Most often, these kilns are used to perform simple tasks such as drying or firing.

For more complex analytical work, muffle furnaces are used, which operate due to special software control.

They allow you to adjust the heating process to several different levels. Control is carried out using a microprocessor with a digital indicator and an audible alarm.

If necessary, the program can be launched in automatic mode.

To choose a good oven, needs to be checked equipment for the absence of any mechanical damage (chips, abrasions, scratches and others) on all components.

Useful video

Check out the video to see what a large volume metalworking muffle furnace looks like.

Rules for the safe use of high-temperature furnaces

These devices are widely used in various areas of modern industry. Their popularity is determined by the design features and technical characteristics, thanks to which it is possible to process materials and finished products without their interaction with foreign substances. In order for the furnaces to bring maximum benefit, they must be chosen correctly, taking into account all the features of the equipment.

Attention! Compliance with the rules safety precautions will not only help prevent the occurrence of dangerous situations, but will also extend the service life of the device itself.

For safe operation it is necessary to follow the rules:

- Do not process products for which not provided devices;

- do not use equipment even with minor damage;

- Do not allow the oven to operate frequently power grid interruptions.

Comments