A loyal friend of the artist-jeweler – a convenient muffle furnace for enamel

Enamel is thin glass-type coatingIt is obtained by high temperature processing.

The substance is used when required provide protection of ferrous metals from corrosive effectsThis makes it possible to replace expensive alloys with ordinary iron.

How do muffle furnaces for enameling with a programmer work?

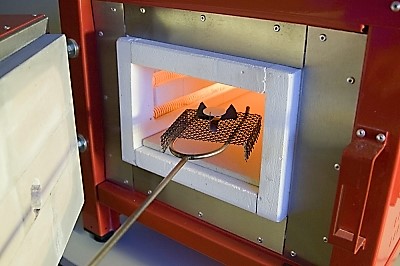

A muffle furnace is a device for heating metal to the desired temperature. The unit got its name due to the presence of muffle, necessary to protect the material being processed.

Closed chamber protects the enamel from direct contact with fuel. When exposed to heat, the material is located inside hermetically sealed box, so the procedure takes a long time.

However, the work process is more qualitative. On metal various scales do not form, it keeps the surface clean.

The enameling furnace includes in its design fan, with the help of which harmful substances released during heating are removed. The device is also equipped with regulator, allowing you to set the required temperature for work. Modern models include computer technologies (programmer), automating the process. Thus, a program that performs certain operations can be specified.

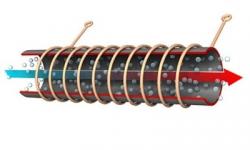

Heating of metal objects placed in the box is carried out by special heating elements. As a rule, there are several of them. The number of such components directly depends on the size of the internal space. Heaters are divided into two types:

- OpenThey are characterized by high speed heating and the release of harmful substances that adversely affect the quality of the metal.

- Closed. They do not allow the negative influence of external factors. Such components can be placed in muffles and make the processing process more thorough.

Important! The muffle is being manufactured from various materials, which allow for heat treatment based on unique techniques.

Design and types. How "hot" can ovens be?

Depending on the heating method, the units operate as gas, and on electricity.

All models similar thermal devices unites the presence of a muffle, which is a special chamber for heating.

She is the main component element of the device.

The muffle furnace is produced using refractory materials and steels structural variety.

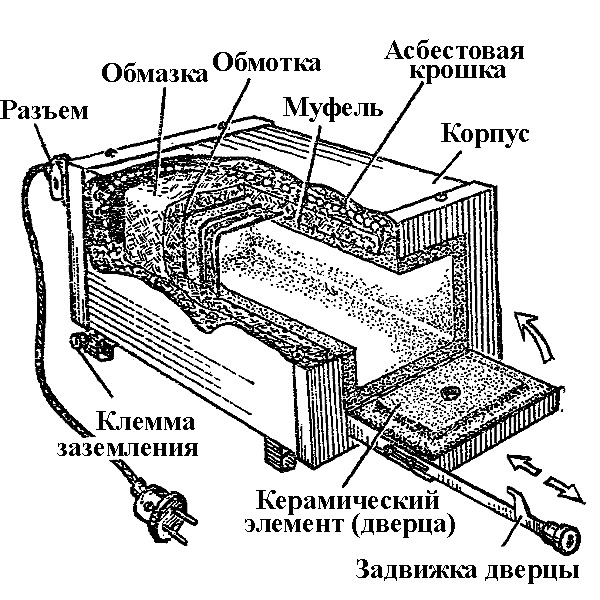

Main elements of the unit:

- Frame, which is made of sheet iron.

- Bottom, cut from steel.

- Basalt is laid out on the inside of the metal body.

- Bricks 7 pieces are joined together in the form of a pipe, forming a space that will become a heating chamber in the future.

- With wire The structure, made of bricks, is wrapped around it.

- Thermal insulation layer is lowered into the metal casing following the brickwork. The efficiency of the entire installation directly depends on this element.

- Working chamber mounted in the furnace body with installed thermal insulation.

- Heating elements are spirals made of nichrome wire.

Photo 1. Schematic representation of the muffle furnace device. The main elements of the design are marked.

Muffle furnaces are divided into depending on the temperature regime:

- On moderate, where the temperature fluctuates from 100 to 500 degrees.

- On average, which are warming up up to 400-800 degrees.

- On high temperature. Capable of giving from 400 to 1400 degrees.

- On ultra-high temperature. They are intended for special occasions and are heated. up to 2000 degrees.

Important! The furnace belongs to one of the described types determined by heating elementsThe more such components are included in the device, the higher the temperature and the larger the dimensions.

Each mentioned variety is used for specific tasks and has positive and negative sides. More powerful device costs more and demands more fuel to effectively perform its functions. All these factors should be taken into account when purchasing.

How to choose a muffle furnace for firing and melting enamel

To make the right choice and purchase the most suitable enameling unit, you need to determine, for what purposes a similar device is required.

In this case, they focus on sizes of objects, which will be subjected to heating. Pay attention to the temperature regime.

Today, models of muffle furnaces with various characteristics:

- Educational The furnace is well suited for hardening, roasting and annealing. The maximum heating of the working chamber reaches 1100 degrees.

- Muffle furnace for jewelers refers to the number professional. To select a unit of this category, the melting temperature of precious metals (platinum, gold or silver) is taken into account. Most often, furnaces equipped with computerized system control. This function ensures the most convenient and continuous operation.

- Dental the furnace is used for the production of prostheses, drying, heating or firing. For such purposes, a device with a working chamber is well suited small sizeThe maximum temperature of such a model reaches 1150 degrees.

Advice. Each described option has certain positive and negative sides. In order to choose the most suitable device, it is important to decide for what purposes A muffle furnace is required.

When buying, you can't lose sight of price, since powerful models have a higher price and dimensions.

Useful video

A video showing the intricacies of working with hot enamel and safety precautions when using a muffle furnace.

Scope of application

Muffle furnaces are widely used for working with enamel in metallurgical production for the process:

- hardening;

- annealing;

- vacations;

- aging;

- cementing;

- nitriding;

- cyanidation;

- diffusion metallization.

Similar devices are also used for research in special metallurgical laboratoriesIn addition, muffle furnaces are designed for melting precious metals, roasting ceramics, drying electrically conductive materials and elements, sterilization medical instruments and burning.

Comments