Smokehouse at home: how to make it yourself?

You are viewing the section Homemade, located in the large section Smokehouse.

Smoked foods are very popular with millions of people. You can buy them or make them yourself at home.

To prepare smoked dishes: meat, fish, cheese, berries, fruits, vegetables, you can create a home smokehouse.

The dishes prepared in it are valued not only for their original taste. Smoked meats made according to old recipes are also distinguished by harmlessness. Smokehouses of various models and modifications are sold in stores. But you can create such a device yourself.

Content

The difference between a smokehouse for home and apartment and an outdoor one

A home smokehouse differs from an outdoor smokehouse in the source of energy used. Outdoors, fire is used for heating, while indoors, gas or electricity is used. A home smokehouse can also be heated on an electric stove.

Attention! Do not use expensive electric stoves to heat the smokehouse, as the bottom may become deformed during heating and damage the stove.

To create a smokehouse yourself, you need to choose its dimensions. The classic device has the following dimensions: 50x30x30 cm. This device will be convenient for preparing small portions of meat and fish products. It is distinguished compactness and ease of manufacture.

Photo 1. A homemade smokehouse powered by a gas stove. The flue is routed out the window.

To carry out the work you will need:

- metal sheets with a thickness of 2 mm;

- tape measure and square;

- thin reinforcement;

- turbine with metal discs;

- welding machine.

Important! Before you start connecting the parts, it is better to create paper drawing or do pattern diagram on a piece of cardboard to make it easier to cut out pieces of the required size.

Smokehouse details:

- lid (18x45x30 cm);

- lattice (8x30x45 cm);

- pallet (30x45 cm);

- box (45x20x18 cm).

How to make a smokehouse at home with your own hands

Cut out the cross walls from the steel sheet (thirty by thirty centimeters) and longitudinal (thirty by fifty centimeters). The result is a rectangular sheet.

Then the bottom is cut out. It is better to do it a little bit more, to weld with an overlap. The parts are welded at right angles.

The smokehouse must be perfectly sealed, otherwise the acrid smoke and heat will leak through the cracks.

To ensure better quality welding, the seams are additionally welded inside the device.

Reference. In an apartment setting, it is best to use devices for hot smokedThey allow you to cook quickly and do not take up much space.

It is used for smoking wood chips, which does not burn, but smolders at a temperature of at least 60 degrees. The lid of the smokehouse is made into a "house". Thanks to this, small pieces of fish, meat or other products can be placed on the hooks. A water seal for better sealing. For this purpose, a water channel is used, which is poured in last, this prevents smoke from entering the apartment.

The flat lid is made slightly larger so that the smoker cabinet can close freely. A handle is welded to the lid and a small metal smoke exhaust pipe. A tube is better than a hole. It has a small cross-section, it is strong and it is easy to put a hose on it, which is easily led out the window.

For making a home smokehouse, it is best to use stainless steel. It is not subject to corrosion and allows you to use the device for a long time.

Interior diagram

The smokehouse is equipped with: lattice and hooksProducts are placed on them.

How to make a tray to collect fat during smoking?

If you don't use a drip tray, the fat will drip directly onto the smoldering wood chips, ruining the taste of your food. It's easy to make a drip tray. Its size should be a little less, than the size of the bottom. It is placed folded side up.

Photo 2. Disassembled home smokehouse. The fat collection tray is installed on the grate.

The tray is installed on the grate. It is best to make it removable. This will allow you to regularly wash the element, which will not interfere with the loading of chips.

Making the legs

The legs help to conveniently install the grids on which the products will lie. First, they are cut off 4 U-shaped pieces of wireThey are attached to them by welding. transverse pieces of wire. One grid is located at the bottom. Its legs are placed on the pallet. The upper grid is welded with its legs to the frame of the lower one.

The lattice is made from reinforcement using welding criss-crossHooks are made by bending wire.

Reference. Smoked foods are much healthier than fried ones. This is due to the fact that during smoking, fat comes out of the products, which can be deposited in the body as harmful cholesterolIn addition, smoked products last longer than fried ones.

Additional elements

Handles are installed on the sides of the device for easy movement and delivery to the fire. After welding, carefully process the seams, edges and bends using sandpaperThis will prevent scratches from burrs and sharp corners while smoking.

Assembly of the device, drawings

After you have made all the parts, start assembling the structure. There are no big difficulties in this. The parts are attached to each other in the order indicated on the drawing. During the first assembly, it is worth checking, how well do all the parts fit together, so that no problems arise during smoking.

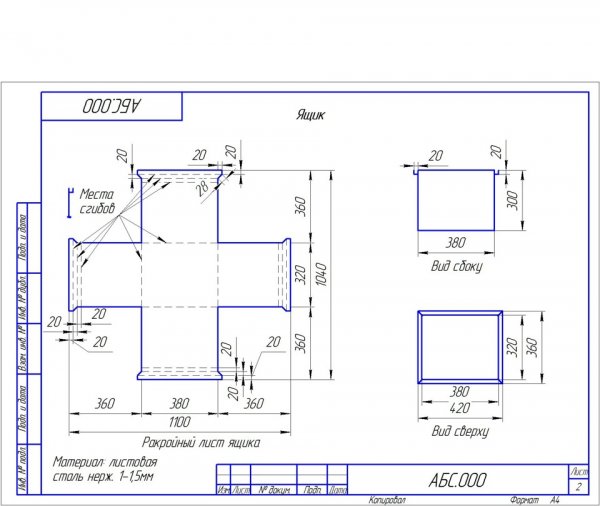

Photo 3. Drawing of a box for a smokehouse: cut-out view, side view, top view. Material: sheet stainless steel 1-1.5 mm.

The lid should easy to install and remove. But if the dimensions and bending angle are not observed, then this element will be inconvenient to use. For example, the lid may jam and it will be possible to remove it only with great effort. This is very inconvenient and dangerous when the smokehouse is already heated. In addition, this can spoil the products, which will simply overheat and become unsuitable for consumption. Therefore, it is worth testing the smokehouse before loading products into it.

Photo 4. Drawing of a portable smokehouse with dimensions and parts of the device indicated.

Difficulties in manufacturing

In order to assemble all the elements of the smokehouse with high quality, It is worth paying attention to the following points:

- Secure the metal well before cutting it with a grinder. The tool creates a powerful vibration and if the material is poorly secured, the cutting line will be uneven and serious gaps will appear between the parts, which are difficult to seal even with welding. Use clamps to secure. This will prevent serious injuries.

- When marking the parts, take into account the thickness of the disc, installed on the grinder. The cutting line must be increased to maintain the dimensions.

- To bend metal at right angles, mark the sheet using a square. The sheet bends easily and evenly if you first tap the bend line with a chisel and hammer. You need to create a small depression along the line. It is easy to bend the metal by placing the bend line on a flat and sharp edge of the table. Bending is done gradually across the entire width of the sheet. Then it will be uniform and the sheet will not be deformed.

Important! To ensure that the products in the smokehouse are not subjected to excessive temperature treatment, install a thermometer in it. The temperature should not exceed 100 degrees.?

Let's sum it up

Assembling a smokehouse for your home is not that difficult if you have the right tools and materials. The size of the device may vary, depending on how much food you will be cooking.

Before building a smokehouse, please read visual aids, which consistently show how to carry out the work correctly.

A homemade device for home smoking will save you money and allow you to enjoy dishes, many of which cannot be bought in the store.

Useful video

Watch the video, which shows the process of making a homemade smokehouse with your own hands.

Comments

Determine the dimensions based on the placement on your stove. It is better to make it for two burners.