High-quality and safe heating: choosing a gas burner for a stove

Gas burners, also called nozzles, are key components of any gas furnace design.

The purpose of such a device is in creating a mixture of fuel, in this case natural gas, and air in order to maintain the combustion process in the heating device.

Construction of gas burners

Distinguish two types similar products:

- The first is called atmospheric.

Such devices operate by absorbing air and are distinguished by their simple design.

Injectors do not need automation and various additional devices, it is enough to ensure good air circulation in the room where the stove is located.

The design of such a device may also include detectors for measuring oxygen levels to prevent dangerous situations caused by low oxygen levels.

It is believed that atmospheric devices have relatively low power, but it is quite sufficient for heating medium-sized rooms. And one can also note the simplicity of the design of such units, their noiselessness and compactness.

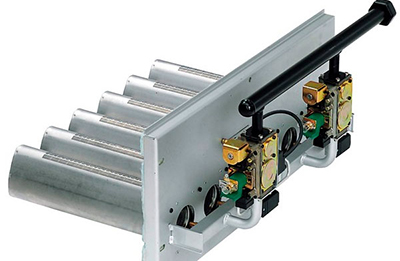

- In turn, supercharged or blowing devices have a more complex design. The basis of such devices is the forced supply of air into the furnace chamber to form a mixture on the basis of which the furnace operates. Due to this mechanism, the correct ratios in the mixture are achieved.

Photo 1. The gas blower burner provides forced air supply to the furnace chamber, where the mixture for work is formed.

The devices are safe, since the processes take place in a closed space. They also have high efficiency rates and are more environmentally friendly devices than atmospheric burners.

Reference! If we are talking about atmospheric units, then the boilers will be with open combustion chambers. In blast boilers, however, they have closed chambers.

How to choose a good device?

The main characteristics of such products are:

- Thermal power.

- Gas characteristics, which will be used in the product.

- Relative flame length, coming out of the burner.

- Calculated gas pressure in the furnace.

- Working adjustment: the ratio of the theoretical thermal power to the minimum.

- Limit adjustment: the ratio of the greatest thermal power to the least.

- Chemical composition of fuel.

- Noise level, produced by the product.

When choosing a device, you need to keep in mind the following factors:

- Simplicity of design. In this case, the cross-sections of the gas passage paths must be the same and create minimal resistance to the gas.

- Room size. For small rooms, an atmospheric device will be sufficient, but for larger rooms, the power of such devices may not be enough.

- Manufacturer of the product. Domestic and foreign (mainly products made in Germany are presented on the market) units have approximately the same cost, but some similar devices are intended for installation in specific types of stoves. For example, domestic product AGG-15 Suitable for use only in stoves with a long fuel mixture channel.

Photo 2. Gas nozzle AGG-26, suitable for furnaces with a long channel.

- Type of heating device.

Important! It is necessary to know, where will the fuel come from to the heating device: from separate cylinders or from the main pipe. This is also taken into account when installing the stove.

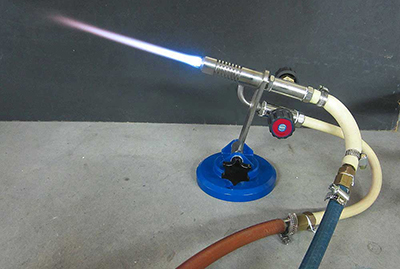

Making a nozzle with your own hands

Before you start using a product made at home with your own hands, you need to go through the following procedures:

- The burner must undergo quality control at the local Rostekhnadzor office in accordance with the regulations established in the Federal Law on the Safety of Buildings and Structures from 30.12.2009.

- After this check it is necessary get a Rostekhnadzor certificate about the suitability of the burner for operation.

To start making the nozzle, you will need the following materials:

- A valve that will serve to regulate the fuel supply to the device. To supply gas to the burner, you need to use a valve installed on the gas source.

- Steel pipe. It is desirable that it has a thickness up to 2 mm and length up to 100 mm.

- Steel cap for making a fuel dispenser. You can also use a nozzle from a blowtorch.

- Steel handle. It can be made from a regular fitting.

- Rubber for handle lining.

- Wire. It will be used in welding.

You will also need the following tools:

- Welding machine.

- Grinder for cutting parts.

For home production, an atmospheric nozzle is preferable due to the simplicity of its design. The procedure is as follows:

- First, the cap is screwed onto the valve. For example, if a standard valve is used VK-74, then the cap has a conical thread.

- Then, by cutting the existing steel pipe to the required dimensions with a grinder, the nozzle of the future injector is being manufactured — its basis.

- Next, The nozzle is welded to the cap using wire. The cap and nozzle should not touch.

- The piezo element is installed, which is needed to activate the device.

After this, the product is ready for installation.

Attention! To install a system for supplying fuel to the stove from the central heating system, special equipment is required experience working with gas systems.

Installation for the stove

When installing the finished unit into the oven, take into account: What materials is it made of:

- If we are talking about a brick oven, then the obvious disadvantage will be the high cost and complexity of such a design, which is assembled only by a specialist. In this case, the nozzle is mounted inside the stove.

- In turn, Installation of the unit in a metal furnace is much simpler and can be done without the involvement of specialists. In this case, the nozzle is mounted directly into the stove so that the flame enters the boiler in sufficient quantity to form a fuel mixture.

The gas nozzle, the heart of the stove, must be of high quality and installed correctly. If there are any problems with the operation of this unit, problems related to fuel may arise, which can lead to to irreversible consequences.

Useful video

The video shows the step-by-step process of making a gas burner.

Conclusion

Gas heating appliances have become an important element in many homes.

To use them you need knowledge of safe use rules such units, standard for all appliances using household gas:

- Carry out any manipulations with such devices without making a preliminary plan for such action.

- Install gas-powered devices, in premises not suitable for this purpose.

- After finishing using the device shut off the fuel supply.

- Be extremely careful when starting a fire indoors., where the fuel supply goes.

- Place the fuel source in a safe place.

By following these rules, the operation of the gas stove will be problem-free and comfortable.