Warm apartment all year round: heating manifold installation and connection diagrams

When choosing a heating system, the main thing is high-quality heating of the apartment, functionality, safety in use and easy repair.

This is especially important in winter, because Low temperatures can cause pipes and radiators to crack.

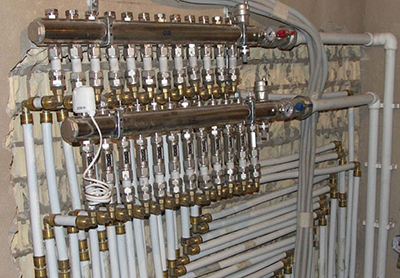

To avoid such problems, a heating manifold is installed.

Content

Purpose of the manifold for the heating system in the apartment: what is it used for?

The collector is hollow comb, which is connected to the heating system. The device is used to regulate the supply of liquids to radiators, a floor heating system or a convector.

At the same time each device, connected to the collector system, has feed and outlet pipe.

That's why it's called a comb, because one part is designed to supply heat to the device, and second - for return and subsequent reheating of the liquid.

Operating principle

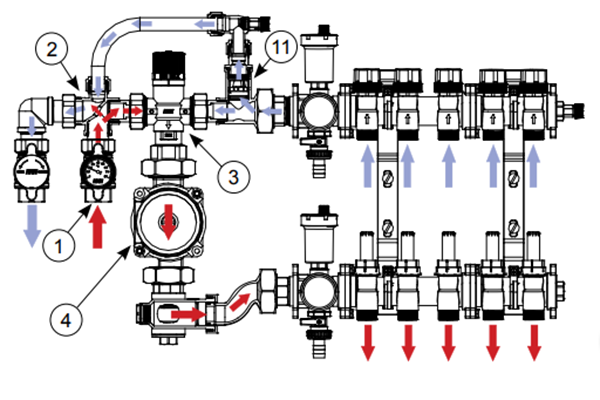

The mixing block is designed for supplying water to convectors with heating to the required temperature - mixing in supplies, if necessary, hotter water from the boiler.

Photo 1. Circulation diagram: water comes out of the mixer (3), passes through the pump (4), installed instead of the extension element.

Water, returning from the loops, enters the reverse side of the collector and via connection (11) enters again in the mixing blockHere, high temperature supply water is mixed with the return water to ensure that the supply temperature to the loops is maintained at the required level.

Heated water is supplied from the boiler through ball valve (1) And branch connection (2). When entering the mixer block, an equal amount of water at a lower temperature is obtained, and the return water is discharged into the boiler through the connection (11) and connection (2).

Scheme

- Two-centimeter pipe with temperature sensor for connecting supply pipelines;

- Connection complete with adjustable bypass for water return into the boiler and back to the heating elements;

- Thermostatic mixer for controlling water temperature, circulating in the system. Regulated in a temperature range from 18 °C to 55 °C;

- Template for installing a circulator with an outlet distance between connections of 130 mm;

- Safety thermostat with probe with adjustable temperature from 10 to 90 °C (recommended 60 °C). The supply temperature is limited by closing the circulator when the set temperature is reached;

- Intermediate connection complete with automatic ventilation valve, bimetal temperature gauge with scale from 0 to 80 °C for reading the temperature of the mixed water flow in the loops and drain cock.

- Pre-assembled chrome plated flanged brass manifolds with flow meter for installation with interchangeable nozzles for copper, plastic and multilayer pipes or with gas connection. These are distribution manifolds for supplying water to panels;

- Manual air release valve;

- Chrome plated flanged brass manifolds with integrated valves. These are water collectors;

- Intermediate connection complete with automatic ventilation valve, bimetallic temperature with scale from 0 to 80 °C to read the temperature of water returning from the heating elements and drain valve;

- Reverse connection with built-in check valve for distribution in the mixer and return line to the boiler;

- Elbow with manual ventilation valve;

- Connecting the return pipe to the boiler;

- Thermoelectric manifolds for delivery to high temperature working system (radiators);

- Thermoelectric collectors for return from high temperature operating system (radiators).

Advantages

- Continuous and uniform heat supply. With the help of a manifold, equal pressure is achieved in all heating elements and the temperature throughout the house will be the same;

- Possibility of adjustment heat - the heating system becomes very flexible. For example, if a certain room does not require heating for a while, it is turned off.

In addition to the radiator, it is also possible to disconnect the pipeline, which will reduce heat loss to 0;

- The system has high maintainabilityEach of its elements is replaced.

Flaws

The main disadvantage is initial installation costs, which include the purchase of materials. Because of which the installation of a manifold for heating will not always be relevant. Sometimes it is better to stay with a standard two-pipe system.

Types

Collectors are divided into: several varieties.

Solar

A solar thermal collector stores heat by absorbing sunlight. A collector is a device to capture solar radiation. Solar radiation is energy in the form of electromagnetic radiation ranging from infrared (long) to ultraviolet (short) wavelengths.

Reference! The amount of solar energy falling on the Earth's surface is on average 1000 watts per square meter under clear skies, depending on weather conditions, location and orientation.

What is it

This design is installed on the roof.

Photo 2. Solar type collector of the heating system, installed on the roof of a private house.

Why is it needed?

A solar collector is needed to collect solar energy and convert it into heat by heating water. Thus, we provide our home with hot water in summer, autumn and spring seasons.

How does it work?

Solar water heaters collect and store heat from the sun by heating a liquid. Solar Heat captured by the "greenhouse effect", in this case the ability of the reflective surface to transmit shortwave radiation and reflect longwave radiation.

Thermal and infrared radiation (IR) are created when short-wavelength light hits a collector absorber, which is then transmitted into the collector.

A liquid, usually water, in contact with the absorber collects the captured heat to transfer it to storage.

Two principles govern solar thermal collectors:

- First, any hot object will eventually lose its heat back to the environment.

The efficiency of a solar thermal collector is directly related to heat loss, mainly from convection and radiation. Thermal insulation is used to slow down the heat loss from a hot object to its surroundings;

- Secondly, heat loss is more rapid if the temperature difference between the hot object and its environment is greater., in this case between the collector surface temperature and the ambient temperature. (But the same applies to the transfer of heat from the collector to the liquid, the greater the difference between the collector and the liquid, the more heat is transferred).

The simplest approach to solar water heating is to simply Place a tank filled with water in the sun. Heat from the sun would warm the metal tank and the water inside. This is how the first systems worked more than a century ago.

Important! However, this setup would be ineffective because limit heat loss from the tank littleAdding an insulated box around and glass on top to keep the heat in won't always help.

A modern collector has a large flat surface (absorber) to receive maximum rays from the sun. Small tubes are also connected to it. The liquid passes through them, collecting heat from the absorber. The sides and bottom of the collector are well insulated, and the glass on top covers the insulation.

It's quite simple, but there are some technical factors that affect the efficiency of the system. One of them is coating on the absorber, which is specially designed to absorb as much heat as possible and give back as little as possible.

Another is glass, which is high carbon and specially coated to receive the maximum possible amount of light energy, and also to prevent as much heat loss as possible.

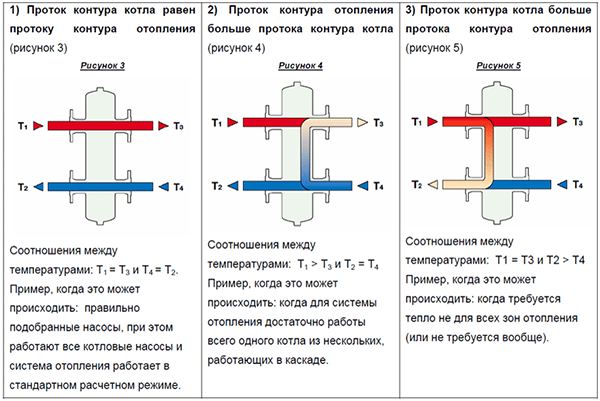

Hydraulic arrow

Hydraulic separators are compact, economical units that allow fast and efficient installation of primary/secondary pipelines for many different boilers.

The installation of this unique device offers additional benefits in removing unwanted air particles and dirt, preventing their damaging effects on system components.

He is especially Suitable for modern boilers, which typically have higher flow resistance.

What is this?

This is a container with several nozzles, to which the heating circuits are connected.

Purpose

The hydraulic arrow reduces the flow rate in the vessel, which allows using two secondary functions in one device - air removal and dirt removal. performs the primary function of removing air and contaminants along with hydraulic separation without the addition of pipe connections or installation costs.

Magnetic dirt removal adds the fourth function to the above. Magnetic separation is particularly effective for older system modifications that may contain large amounts of iron and steel particles.

Photo 3. Table showing the operating principle and temperature relationship formulas of the hydraulic arrow.

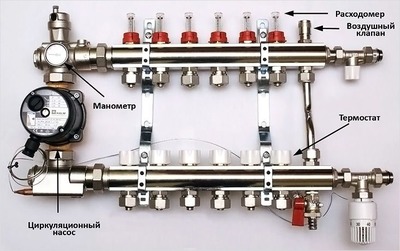

Distribution device or comb

This heating water distribution point into the various circuits/areas to be heated. Supplied pre-mounted on mounting brackets.

Characteristic

Column made of stainless steel, which has high resistance to oxidation and corrosion, so it is much stronger than others that may be made of brass and then chrome plated.

Stainless steel also ensures ease of manufacture, cleaning and reducing potential contamination.

Purpose

It is needed to distribute heating to different elements. In this way, optimal separate heating of radiators that are independent of each other is achieved.

How does it work?

Water comes out of the mixer and passes through a pump installed in place of the extension element.

The water returning from the loops enters the return side of the manifold and through a connection again enters the mixing unit. Here the high temperature water supply is mixed with the return water to ensure that the supply temperature to the loops is maintained at the required level.

The heated water is supplied from the boiler through the ball valve and the branch connection. When it enters the mixer block, an equal amount of lower temperature is obtained, the return water is discharged into the boiler through the connection and connection.

How to choose a radiator manifold distribution group?

It is worth noting that the combs for distribution radiator groups are quite similar in their design.

At the same time choice between manual and automatic mechanism - it's a question of your own comfort and cost. For radiators, this is not at all necessary, especially since all the automation can be added later.

Material

The material comes in the following types:

- Steel. Products made from this material are very durable and expensive. They are intended for those who want to get a high-quality collector for a long time. Such combs are able to withstand very high pressure;

- Brass. A collector made of this material has excellent characteristics and an affordable price. This is the most common type;

- Polymers. These products are distinguished by their low cost, but in all characteristics they are inferior to the previous types.

Of course, the best choice would be a brass product. Since it is quite durable and costs less than steel. The characteristics are quite decent.

Features of polypropylene

It is common to assemble a collector from polypropylene by hand. Due to the insulating properties of these pipes, this is possible, but knowledge and skills are required, so as not to spoil anything.

Attention! The material is available, but if such a device fails, it can be pay more for repairs.

Permissible pressure

This indicator indicates the strength of the collector.

So for large heating systems a manifold capable of withstanding greater pressure will be required. due to the peculiarities of heat supply.

If you need to heat a small room, then acquire a weaker and cheaper one distribution manifold of the heating system.

Capacity and diameter

The capacity and diameter will affect per volume of coolant. The higher this indicator, the larger the size of the radiator or convector installed. This indicator will form cost of the device.

Why are auxiliary elements needed?

So why are they necessary? Air vents, flow meters, etc. help monitor the functioning of the system. However, they also add value to the product.

Useful video

Video about the distribution manifold, its assembly features and installation method.

Conclusion

Oventrop, Rehau – these German companies are considered the best manufacturers of heating collectors.

Comments