What is needed to connect a gas boiler to a gas source?

Usage natural gas for heating a home is the most economical solution, and in some cases the only possible option.

If all current standards and regulations are met during installation work, the gas heating system meets the highest requirements. reliability and safety.

Safety rules when connecting a boiler to a gas source

First of all, pay attention to the parameters of the room in which the heating boiler will be located. With a capacity of no more than 60 kW The device can be placed in the kitchen. Most often, wall-mounted boilers are placed this way.

Photo 1. Gas condensing boiler model Vitodens 100-W, efficiency up to 98%, manufacturer - "Viessmann".

With a higher capacity, a separate room will be required on any floor of the residential building, including the basement. With a total capacity of heating units no more than 150 kW The following requirements apply to the premises:

- construction volume not less than 15 cubic meters;

- height not less than 2.5 m.;

- availability of natural light, glazing area based on 0.03 m² per cubic meter of volume premises;

- availability of ventilation: exhaust in volume triple air exchange, inflow equal to hood plus air volume, necessary for combustion.

For the installation of internal gas pipelines, steel pipes must be used according to GOST 10704-91, GOST 3262-75. To connect a gas boiler, braided rubber hoses and corrugated metal hoses (bellows connection) can also be used. marked "GAS".

Steel pipes are connected by welding; threaded connections are allowed only at the points where shut-off valves are connected.

The installed gas pipelines must be primed and painted with enamel.

What will be useful in the process

To connect the device to a gas source, in addition to the boiler itself and metal pipes, you will need:

- thermal shut-off valve;

- electromagnetic valve;

- gas alarm;

- shut-off valves;

- gas meter;

- pressure gauges;

- primer and enamel;

- gas filter (optional);

- may be needed bellows connections marked "GAS" They are preferable to rubber hoses.

Depending on the situation, other auxiliary materials may be needed.

The connection points of the bellows piping with the pipe, fittings and devices must be sealed with a paronite gasket. This material, unlike rubber, is not subject to deformation.

How to connect a gas boiler

The procedure for connecting boilers to the source:

- Receiving technical conditions in a gas distribution organization for connection to gas supply networks.

- Execution design work, necessary approvals of design documentation.

- Execution construction and installation works, including gas piping of boilers, development of executive documentation.

- Testing and pressure testing gas pipelines.

- Connection to the gas main, gas start.

It is important to take into account that gas boiler houses are objects of increased danger.

Therefore, all work related to design, installation and operation must be carried out by organizations with with appropriate permits and certified personnel.

And the work on direct connection to the gas main and gas start-up is carried out gas distribution organization, which issued the technical specifications.

In any case, it does not hurt to know the correct location of the gas piping elements. The first device after gas is introduced into the room should be thermal shut-off valve, after him electromagnetic valve. Then it is recommended filter, after - gas meter. Next, from the main gas manifold, lines are made to the gas boilers with taps and pressure gauges installed on them to control the pressure.

Connection to bottled gas

It is not always possible to connect to gas networks, as they are not laid everywhere yet. For such cases, there is an option to convert the boiler to operate on liquefied gas from a cylinder.

Natural gas boiler burners operate under average pressure 20 mbar (0.002 MPa), and liquefied gas comes from the cylinder under pressure 3-4 mbar.

When choosing a boiler with a liquefied gas burner, it is better to give preference to a model in which the burner operating pressure is as low as possible.

This will allow you to save significantly on fuel due to the most complete emptying of the gas cylinder.

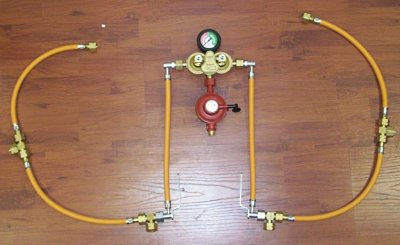

Burners for burning liquefied gas may be included in the basic boiler package. Otherwise, it will have to be purchased separately. In such a system, a reducer will be needed to connect to the cylinder. Reducer and other necessary fittings can be purchased both from boiler equipment suppliers and at cylinder filling stations. The reducer for a heating boiler must have a higher throughput than the more common reducers for gas stoves.

For a private house with an area of 100 m² for heating and water heating purposes, an average of 8-9 gas cylinders per month during the heating season. Cylinders may be combined into group installations (up to 15 pieces). They are placed in a metal cabinet, which is located in a separate ventilated room.

Liquefied gas is heavier than air, so there should be no basements or cellars in the room with cylinders. Moreover, they cannot be stored in basements or ground floors.

It is not allowed to install cylinders outside, at low temperatures it will occur gas pressure reduction, and the combustion process will be disrupted.

For supplying gas from reducers to boilers it is best to use metal corrugated hosesThey are less subject to wear than rubber ones and less subject to vibration and deformation when replacing cylinders than a pipe system.

The finished assembled gas piping system must be pressurized with compressed air and then a test gas run must be performed. These works must be carried out specialized organizations, which have the appropriate approvals.

Attention! Elimination of detected gas leaks under pressure forbidden!

Useful video

Watch the video to learn how to install a gas boiler correctly.

Gas heating - savings, safety and comfort

Properly executed design documentation, high-quality installation of the system, compliance with safety regulations, the use of modern equipment, equipping the system with automation and control will provide you with safety, savings on utility bills and comfort in the home.