Tirelessly drives the coolant back and forth - a water pump for heating a private house

Gravity heating systems for private homes often operate inefficiently due to improper assembly, which provides for the angle of inclination of the pipes.

There are schemes in which radiators are arranged sequentially in the direction of coolant supply.

In them the last batteries do not receive enough thermal energy, which means that the rooms where they are installed will be cool. The problem is easily solved - with a water pump for the heating system, which is called a circulation pump.

Its main task is to drive the coolant along the circular scheme of the assembled heating system, evenly distributing heat across the radiators. Minimum speed hot water movements - 20–25 cm/s, which is sufficient when speaking about distribution. Maximum — 1.5 m/s.

Design features of a pump for heating a private house

In principle, a circulation pump for heating is no different from other types of water pumps.

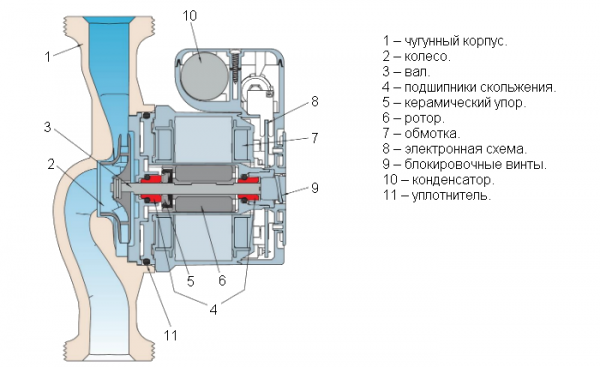

It has two main elements.: an impeller on a shaft and an electric motor that rotates this shaft. Everything is enclosed in a sealed housing.

But There are two types of this equipment, which differ from each other in the location of the rotor. More precisely, whether the rotating part contacts the coolant or not. Hence the names of the models: with a wet rotor and dry. In this case, we mean the rotor of an electric motor.

With wet rotor

Structurally, this type of water pump has an electric motor in which the rotor and stator (with windings) are separated by a sealed glass. The stator is in a dry compartment where water never penetrates, the rotor is located in the coolant. The latter cools the rotating parts of the device: the rotor, the impeller and the bearings. In this case, water also acts as a lubricant for the bearings.

This design makes the pumps low-noise because the coolant absorbs the vibration of rotating parts. Serious flaw: short Efficiency not exceeding 50% from the nominal value. Therefore, pumping equipment with a wet rotor is installed on heating networks of small length. For a small private house, even in 2-3 floors, this would be a good choice.

To the advantages wet rotor pumps, In addition to silent operation, you can add:

- small dimensions and weight;

- economical consumption of electric current;

- long and uninterrupted operation;

- easy to adjust the rotation speed.

Photo 1. Diagram of the device of a circulation pump with a dry rotor. The arrows indicate the parts of the structure.

Disadvantage - cannot be repaired. If any part fails, the old pump is dismantled and a new one is installed. There is no model range in terms of design capabilities for wet rotor pumps. They are all produced in the same type.: vertical design, when the electric motor is located with the shaft down. The outlet and inlet pipes are on the same horizontal axis, therefore the device is installed only on a horizontal section of the pipeline.

Important! When filling the heating system, the air pushed out by the water penetrates into all the voids, and including into the rotor compartment.

To release the airlock, you need to use with a special drain hole, located at the top of the electric motor and closed with a sealed rotating cover.

Preventive measures for "wet" circulation pumps not required. There are no rubbing parts in the design, cuffs and gaskets are installed only on fixed joints. They fail because the material has simply aged. The main requirement for their operation is not to leave the structure dry.

With dry rotor

Pumps of this type there is no separation of rotor and stator. This is a regular standard electric motor. The design of the pump itself has sealing rings that block the access of the coolant to the compartment where the engine elements are located. It turns out that impeller mounted on the rotor shaft, but is in the water compartment. And the whole the electric motor is located in another part, separated from the first by seals.

Photo 2. Circulation pump with dry rotor. At the rear there is a fan for cooling the device.

These design features made dry rotor pumps powerful. Efficiency reaches up to 80%, which is quite a serious figure for equipment of this type. Disadvantage: noise, produced by the rotating parts of the device.

Circulation pumps are presented in two models:

- Vertical execution, as in the case of a wet rotor device.

- Console — this is a horizontal design, where the device rests on the legs. That is, the pump itself does not press on the pipeline with its weight, and the latter does not serve as a support for it. Therefore, a strong and level plate (metal, concrete) is necessarily laid under this type.

Attention! The sealing rings often fail, becoming thin, which creates conditions for the penetration of the coolant into the compartment where the electric part of the electric motor is located. Therefore preventive maintenance is carried out every two or three years device, inspecting the seals first.

Criteria for selecting a water pump for the system

If we are talking about a small private house, then the best solution is to purchase a pump with a wet rotor. What characteristics should you pay attention to?, choosing it:

- Devices of this type operate on a 220V AC network. Therefore, the power of the electric motor does not exceed 100 W, the minimum parameter is 50 W. The difference in cost between the two models is not very large, so it is recommended to choose the maximum parameter, taking into account the size of the heating system itself.

- Number of gear shift modes. According to this criterion, devices are divided into single-mode and those with the ability to change the rotor speed. By the way, the latter are designated in the marking letter "S". It is better to choose exactly these.

- Permissible coolant temperature. Perfect +110 °C.

- Safety class IP44.

- Connection type - flanged or threaded. Here, it is at the discretion of the installation contractor.

- Maximum pressure in the system 10 barPlease note, this is not the pump pressure.

And two main characteristics: performance and pressure. They are selected based on the area of the house being heated. The ratio is:

| House area, m² | Productivity, m³/h | Head, m |

| up to 200 | 1.25 | 1 |

| 350 | 2 | 2 |

| 500 | 3 | 2 |

| 900 | 5 | 3 |

| 1100 | 7 | 3 |

This is the ratio does not take into account the branching of the system, the number of shut-off valves. But it is precisely on these parts that significant power losses occur.

At the same time It is necessary to take into account the temperature regime operation of the heating system. Here the temperature of the coolant at the outlet of the boiler and at the inlet is taken into account.

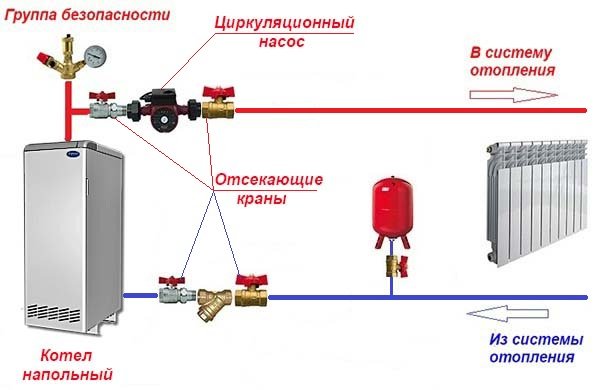

Requirements and installation diagram

Installing a circulation pump in a heating system is not a very complicated process. But there are nuances that you need to know.

Most often, installation is carried out to the return circuit of the system near the boiler, where the coolant temperature is minimal.

This is done in order to avoid overheating of sealing products, which can lose their qualities under the influence of hot water. That is why it is recommended to choose pumps with an acceptable coolant temperature of +110 °C.

If a solid fuel boiler is used as heating equipment in a private home, then installing a pump on the return line is preferable. Because in such boilers the water temperature can reach critical values.

If a circulation pump is installed on a heated floor system, then, on the contrary, mounted on the supply circuit. The reason is the formation of air pockets, which the device will push through with its pressure.

Before the pomp A mesh filter must be installed.

It is better to install a check valve after the device., it will prevent the coolant from moving back if the electricity is cut off and the pump does not pump water. In addition, the valve protects the equipment from water hammer.

Wet rotor pump can be mounted only in a horizontal plane.

It is necessary to ensure free access to the device. for its maintenance and repair.

If a universal heating system is planned for the house, then the pump is bypassed. The latter will be switched on when the device is switched off.

Photo 3. Diagram of installation of a circulation pump in a heating system on the supply circuit (marked in red).

How to install correctly

As for installation, it all depends on the type of connection. If it is flange connection, then flanges are welded onto the mating pipes. If threaded connection, then union nut fittings are installed. When connecting with flanges, a rubber or paronite gasket is placed between the mounting planes.

The main task of the work supervisor is correctly make a pipe cut for installing a pump. To do this, measure the distance between the device's pipes and transfer it to the pipe. Manufacturers usually indicate this size in the product's passport. But to be sure, it's better to take measurements.

Attention! The circulation pump must not be turned on if the heating system is not completely filled with coolant. And although the device has outlet holes, It is better to wait until the network is completely full.

Useful video

Watch the video, which talks about the features of installing pumps in heating systems.

In conclusion

And the last thing. The pump operation is adjusted empirically.. You shouldn't overload the device, even for the sake of your own comfortable living conditions. If something doesn't suit you about the temperature regime in the house, then you need to buy a pump with a higher capacity.