One of the most important parts of the system! Expansion tank for open type heating

In a heating structure, an expansion tank can rightfully be called an indispensable element. Operation of the tank ensures full movement of the coolant without unexpected leaks and pipe ruptures.

This phenomenon occurs during the process of heating the liquid, its natural expansion and, as a result, an increase in pressure in the system. The excess coolant is compensated for by the expansion tank.

Content

Open type expansion tank for heating systems

Large heating structures use expensive closed-type tanks.

They are characterized by the tightness of the housing. with internal rubber partition (membrane) thanks to which the pressure is regulated during the expansion of the coolant.

For full operation of home systems, open type expansion tank - suitable alternative, which does not require special knowledge or professional training for the operation and further repair of equipment.

An open tank performs some functions for the smooth operation of the heating mechanism:

- "takes" excess heated coolant and "returns" cooled liquid back into the system to adjust the pressure;

- removes air, which, thanks to the slope of the pipes with a couple of degrees, rises itself to the open expansion tank located at the highest point of the heating system;

- open design feature allows you to add evaporated volume of liquid directly through the top cover of the tank.

Operating principle

The work process is divided into four simple steps:

- the tank is two-thirds full under normal conditions;

- increasing the amount of liquid entering the tank and an increase in the filling level when the coolant is heated;

- liquid leaking from the tank when the temperature drops;

- stabilization of coolant level in the tank to its original position.

Design

Expansion tank shape exists in three variants: cylindrical, round or rectangular. There is a cover for inspection on the top of the body.

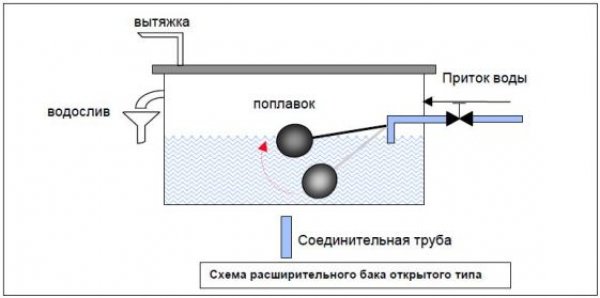

Photo 1. The structure of an open expansion tank for heating systems. The components are indicated.

The body itself is made from sheet steel, but in a homemade version other materials are also possible, for example, plastic or stainless steel.

Reference. Tank coated with an anti-corrosion layer, to prevent premature destruction (primarily, this concerns iron containers).

The open tank system includes several different pipes:

- for connecting the expansion pipe, through which water fills the tank;

- at the junction of the overflow, to pour out excess;

- when connecting the circulation pipe, through which the coolant enters the heating system;

- for connecting the control pipe, designed to eliminate air and regulate the filling of pipes;

- spare, necessary during repairs to discharge the coolant (water).

Volume

Correctly calculated tank volume affects the duration of operation of the joint system And uninterrupted functioning of individual elements.

A small tank will lead to the failure of the safety valve due to frequent activation, and too large a tank will require additional funds for purchasing and heating the excess volume of water.

An influential factor will also be availability of free space.

Appearance

Open tank - a metal tank whose top is simply closed with a lid, with an additional hole for adding water. The tank body can be round or rectangular. The latter option is more practical and reliable for installation and fastening, but the round one has the advantage of hermetic seamless walls.

Important! Rectangular tank requires additional reinforcement of the walls with an impressive volume of water (homemade option). This makes the entire expansion mechanism heavier, which must be lifted to the highest point of the heating system, for example, to the attic.

Advantages:

- Standard form. In most cases, it is a rectangle that can be installed and connected to the general mechanism independently.

- Simple design without an excessive number of control elements, which allows you to easily control the smooth operation of the tank.

- Minimum number of connecting elements, which gives the body strength and reliability during operation.

- Average market price, due to the above facts.

Flaws:

- Unattractive appearance, without the possibility of hiding thick-walled bulky pipes behind decorative panels.

- Low efficiency.

- Using water as a heat carrierWith other antifreezes, evaporation occurs faster.

- The tank is not sealed.

- The need for constant addition of water (once a week or once a month) due to evaporation, which, in turn, affects the airing and normal functioning of the heating system.

- Presence of air bubbles leads to internal corrosion of system elements and a reduction in service life and heat transfer, and the appearance of noise.

Installation location

The open tank is installed at the highest point of the heating system. There are several installation options:

- On serve. The classic version involves installing a tank above the boiler. With this design, hot water (heat carrier) not only flows along the circuit, but also penetrates into the tank, creating a characteristic noise reminiscent of boiling water in a kettle.

Attention! In case of erroneous calculations the coolant may boil in the tank.

- On the returnThis method allows you to avoid problems with boiling, thanks to the reduced temperature of the liquid.

- Combined. This method involves the installation of two expansion tanks - one at the point of supply of the coolant, and the second on the return. Such a combination allows to avoid air pockets forming in the system.

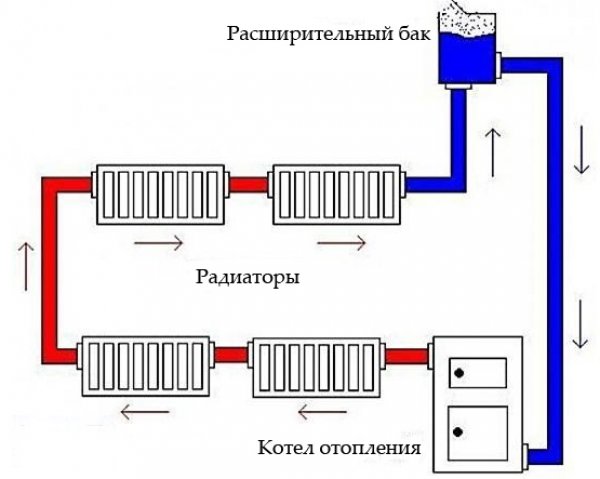

Photo 2. Diagram of a heating system with an expansion tank. In this case, it is installed on the return line.

How to install correctly

When installing an open expansion tank, there is several effective recommendations used by experienced specialists for reliable results:

- Cutting in the emergency drain pipe, to prevent the coolant from overflowing over the top of the tank.

- Insulation of the body tank.

- Placement of the tank directly above the boiler and connection to it by a vertical supply line.

- Insulation of the pipe connecting the tank to the general systemThis will help to avoid an explosion due to the fact that the increased volume of coolant will have nowhere to go.

- Insulation of the drain pipeto avoid water overflowing when it freezes or to protect yourself from harmful antifreeze vapors.

- Installing the tube (flexible hose located inside the tank) to the very bottom. This will help to make maximum use of the tank space.

How to make it yourself from plastic containers or stainless steel

You can make an expansion tank yourself. A tank will do for this 10-12 liters (depending on the exact calculations of the volume of the coolant of the general system).

If you have a ready-made base, for example, a plastic container, you should check its capacity (with regular 3-liter jars), and then attach the missing elements.

Usually the tank is made of stainless steel sheet 2-4 mm thick.

Tools:

- welding machine, welding electrodes;

- grinder with appropriate discs;

- sheet metal (stainless steel);

- pipes;

- various bolts, a set of fittings;

- rubber gaskets;

- brush, gloves, protective mask;

- oil paint;

- thermal insulation materials;

- metal file;

- roulette;

- tank diagram with all dimensions.

Marking a sheet of metal

First of all, it is necessary to make markings on the sheet metal. To do this, you can use a cutting map with paper parts, allowing the use of metal with minimal waste. When joining on a sheet two parts, it is necessary to take into account the thickness of the grinder circle, which can “eat” a few millimeters.

Important! All work must be carried out carefully. followed by cleaning the edges.

Cutting out blanks

The tank body consists of of five or six rectangles (depending on the presence of a lid). If desired, the top part of the lid can be divided into two parts in a way that is convenient, welding one part to the base and attaching the second to the curtains.

Welding a homemade device

The cut out blanks need to be put it at a right angle and weld it. The method of fastening can be different - gas is perfect for 2 mm steel sheets, and with 3-4 mm It is good to work with sheets using electric welding.

At the bottom of the case it is necessary make a hole and weld a pipe into it, through which the coolant will enter the tank. The pipe itself, accordingly, is connected to the circuit of the general heating system.

Insulation

The open heating structure is distinguished by the installation of an expansion tank at the highest point of the system. Typically, this is an unheated attic, where the temperature in winter is often below zero. Under such conditions, the water in the tank can freeze, damaging the entire system. To avoid such a problem, the tank should be insulated with special materials, for example, basalt wool.

Such heat insulation the material is resistant to high temperatures, which is a necessary condition, since the water in the tank boils at elevated temperatures.

Adding oil

The design of the homemade tank, in addition to the main pipe connecting the tank to the system, additional elements are welded:

- to replenish the system or add coolant (water, oil);

- for emergency drainage of excess coolant into the sewer.

Important! The drain pipe must be positioned above the maximum tank fill levelto prevent liquid from spilling over the top.

Water evaporates from the tank through the hole in the lid and air can enter the system. This leads to overheating of the pipes and poor circulation of the coolant. To solve this problem professionals recommend pouring a little oil into the tankIt will cover the surface of the coolant with a thin film, thus creating a protective layer against air penetration.

Calculation of the volume of the unit

The required volume of the tank will be the sum of several components:

- 5% from the total volume of the system;

- 2% taking into account the evaporation of the coolant;

- 1% - a reserve to prevent water from overflowing over the edge of the tank.

To find out the amount of coolant in the system, you need to sum up the volume of the boiler, radiator pipes and heating, and 5% is a theoretical calculation for water.

If a different coolant is used in the system, then an adjustment is required based on the corresponding norm of thermal expansion of this liquid.

Reference. Indirect determination of the system volume is carried out thanks to the boiler power - 1 kW is designed for 15 liters of coolant.

Photos of tanks

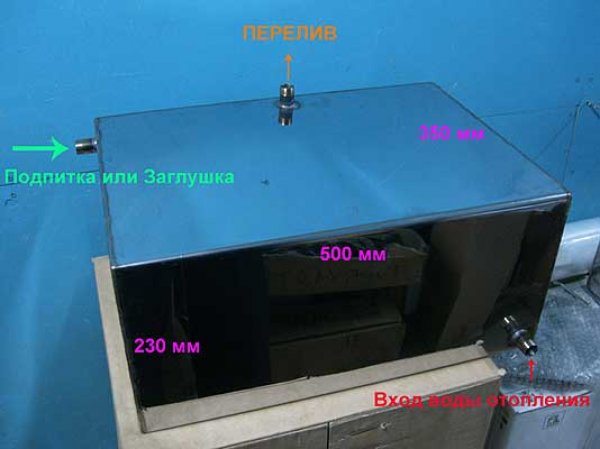

Photo 3. Open type expansion tank. The dimensions of the sides of the unit and the names of its parts are indicated.

Photo 4. Open expansion tank in the heating system. It is located next to the boiler.

Photo 5. A homemade expansion tank made from a plastic canister. It is located in the attic.

Useful video

Watch a video review of a homemade open-type expansion tank made of plastic.

Minimum requirements for the expansion tank

The simplicity and functionality of the open structure allow heating of houses even with unstable power supply. The expansion tank is an important link in the entire heating chain. For normal operation it must have some reserve, which will ensure the safety of both the coolant and the joint system as a whole.