Economical and reliable, but is it safe? How to make a pyrolysis boiler with your own hands

Behind the beautiful flame of burning wood lies a complex chemical process.

In fact, It's not solid wood that burns, but gases, which are released from them at high temperatures. This process is called pyrolysis.

Content

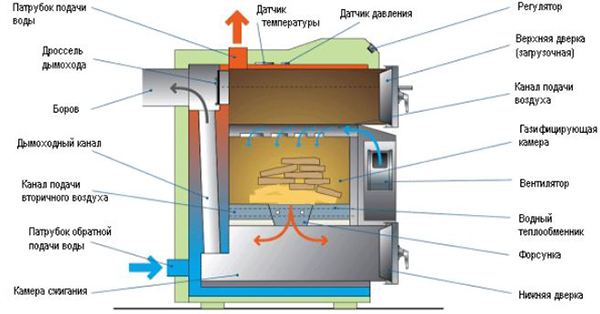

What does a pyrolysis boiler consist of?

The principle of fuel decomposition and combustion of the resulting gases is used in pyrolysis boilers. Combustion occurs at high temperatures and completely.

Design such boilers more complicated than conventional grate, they are more expensive, but much more effective.

The pyrolysis boiler consists of:

- From the primary chamber. It resembles a conventional boiler firebox, into which fuel is loaded. Depending on the design, combustion can occur either at the bottom of the fuel chamber or from top to bottom.

- Secondary chamber. In it, the pyrolysis gases are mixed with secondary heated air and the resulting mixture is hotly burned. Due to the high temperature, complete oxidation of carbon to carbon dioxide occurs.

- Air supply, separation and heating systems. There are boilers with natural draft or forced air supply.

- Heat exchange and smoke removal systems.

- Automatic control.

How does top loading gasifier equipment work?

Firewood in a top-loading pyrolysis boiler burns like this:

- The loaded firebox is ignited, the flame on natural draft heats the firebox to a temperature in the primary chamber 60 °C.

- The door closes and the primary air supply is turned on. In a few minutes the temperature in the combustion chamber reaches 600 °C — the optimal mode for decomposition of gases. Firewood smolders when there is a lack of oxygen.

Photo 1. The pyrolysis boiler firebox is loaded with firewood; the flame heats it up to 60 °C under natural draft.

- Air previously passed through the flame of the primary chamber is fed into the secondary chamber. Hot gases mix to produce a mixture with a stoichiometric number – the optimal ratio of air and combustible gas.

- Passing through the nozzle, the mixture ignites and burns, releasing a large amount of heat. Part of the heat is spent on maintaining combustion in the primary chamber.

- The heat is captured by a system of heat exchangers, and the released carbon dioxide is removed through the chimney.

Making a device with your own hands: step-by-step instructions

The high cost of a factory-made pyrolysis boiler encourages folk craftsmen to build copies of factory-made boilers with their own hands or independent search for innovative technical solutions. The process of building such equipment is complex, but interesting.

Selecting a diagram and drawing

Before starting work, the most important stage is project selectionIf possible, it is worth purchasing a ready-made project that has already been tested, so as not to learn from your own experience.

Photo 2. Scheme of self-assembly of a pyrolysis boiler with a flue channel and an upper loading door.

What should be taken into account when designing and creating a drawing:

- Burner power. It depends on the area of the primary combustion chamber and the size of the firebox, as well as on the intensity of oxygen injection.

- Firebox size. It determines how much fuel will be added, and therefore how long the boiler will operate without recharging.

- Type of supercharging. There are boilers with natural draft, but they do not provide stable combustion of gases. Both a blower fan and a smoke exhauster can be installed on the boiler.

- Type of heat exchanger. The exhaust heat must be captured efficiently. A water jacket or plate heat exchanger on the exhaust will do the job well.

- Lining of primary and secondary chambers, as well as a method for regulating primary and secondary air.

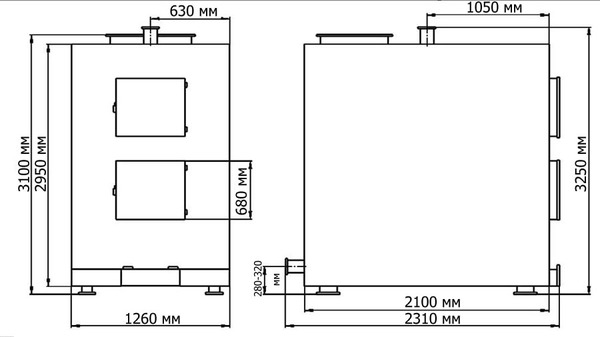

Photo 3. Example of a drawing of a long-burning pyrolysis boiler with the specified dimensions. Side and front views.

Materials and tools

To build a pyrolysis boiler with our own hands we will need:

- High-alloy steel sheets 4 mm thick. They are easier to weld and will not burn out from high temperatures.

- Forced-blowing fan and automation.

Reference! The option is more expensive - factory fan and smooth control controller, cheaper option – a car heater fan, a step regulator and a simple damper for precise adjustment.

- Lining material. The secondary combustion chamber must be lined with a refractory layer, since the combustion temperature of pyrolysis gases is 1200 °CThis could be kaolin wool or fireclay brick.

- Pressure and temperature sensor.

- Pipes, fittings, rods, curtains, valve ball, heat-resistant paint.

To build a boiler, you need an equipped metalworking shop. The craftsman will need skills in marking and fitting parts, the ability to read drawings and cut metal.

We will need:

- Tools for metal processing and joining. Angle grinder, welding machine, electrodes. Ideally, the parts will be cut to order on a CNC laser machine - this will add beauty and make the task easier.

Attention! Follow the rules for safe use of tools. integrity of wire insulation, Watch the direction of sparks when cutting metal.

- Measuring instruments: compass, ruler, square, tape measure.

- Tools for processing fireclay bricks: Angle grinder disc with carbide tips.

Progress of work

Step-by-step construction instructions:

- Marking of primary and secondary chamber parts. The size of the secondary chamber is selected so that the fireclay bricks are laid without trimming. The bottom of the primary chamber is narrowed and ends with a slot nozzle for gas combustion.

- Marking and air access arrangement. On one side, a fan is placed on the air duct made of a square pipe, on the other, the air is divided into primary and secondary.

The amount of air supplied is regulated by a valve - a large diameter bearing ball welded to a bolt or a ball valve. It shuts off the air supply.

- Installation of primary and secondary air ducts. It should be taken into account that the pyrolysis gas nozzle heats up strongly, this energy should be effectively removed by air ducts. The secondary air should be hot, otherwise the combustion will be uneven. The air nozzles should be parallel to the movement of pyrolysis gases.

- The pyrolysis boiler has two chimney outlets - from the primary and secondary chambers. After ignition and air supply, the primary chamber flue is closed - it is necessary to plan a sealed damper with a clamping mechanism.

- Lining the secondary chamber.

- We cover the structure with a 3 cm thick water jacket. To increase strength, connections can be provided; all seams must be sealed.

- An additional plate or tubular heat exchanger is installed at the root of the chimney. You can use ready-made radiators, but due to possible soot clogging, cleaning them will be more difficult.

- The housing contains technological sockets for temperature sensors. - in the water jacket, the thermocouple can be installed in the smoldering zone and the secondary chamber.

- The loading and secondary chamber doors are hung. Opposite the heat exchanger, a cleaning hatch is attached with bolts.

- For an aesthetic appearance, the boiler needs to be painted, It is better to use heat-resistant paint with a hammer effect.

Photo 4. Floor-standing pyrolysis boiler indoors, painted blue with heat-resistant paint.

Correct connection

The pyrolysis boiler has several features when connecting. The decomposition of the fuel is hindered by the low temperature of the coolant, so a three-way valve is installed on the piping.

Attention! When kindling, the liquid circulates in a small circle, when reaching 60 °C the coolant begins to heat the heating system. The outlet pipe and the small circle must be made of metal.

Boiler room equipment

To operate a homemade pyrolysis boiler, you will need a separate equipped room - boiler room.

The boiler room must have a chimney outlet and natural ventilation.

The location for installing the boiler is chosen so that there is access to all surfaces and cleaning.

In front of the firebox, a platform made of non-combustible materials is equipped; to install the boiler, you will need foundation. The chimney connection should be as short as possible.

Difficulties in assembling the boiler

The main difficulty in building a pyrolysis boiler is choosing the right design and materials. Without understanding the processes that occur in the furnaces, it is impossible to build a boiler correctly.

The main mistakes made when designing on your own:

- Insufficient lining of combustion zones. Fireclay bricks are important because they maintain a constant temperature in the combustion zone and protect the grate and firebox walls from burning out.

- Excessive heat removal. The heat exchanger must capture the heat that is not needed to maintain the internal processes in the boiler. The location of the water jacket near the combustion zone is unacceptable.

- Mismatch between the dimensions of the loading chamber and the gasification chamber. A gasification chamber that is too small may cause large logs to become stuck.

- Incorrect size or direction of air nozzles. The mixing of air and pyrolysis gases should be as uniform as possible.

- Poorly made adjustment of primary and secondary air flows, no forced oxygen supply. It is necessary to install either a smoke exhauster or a blower fan with power control.

How to check the operation of homemade equipment?

The result of long-term work on choosing a boiler project and implementing this project will be economical and reliable source of heat. A well-functioning boiler has the following qualities:

- Correctly selected power. Pyrolysis has a small range of adjustments. The boiler cannot be "strangled" or "accelerated" strongly. In this case, combustion either stops completely or begins in the gasification chamber. Therefore, the boiler capacity must correspond to the heat loss of the house.

- Possibility of long-term operation in forced mode. One bookmark should be enough for a long time.

- Easy access to gasification, the pyrolysis torch in the afterburning chamber should already be observed 15–20 minutes after ignition.

- The temperature of the gases in the chimney should not be higher than 40–60 °C. If the temperature is higher, we increase the area of the heat exchanger.

- When testing the boiler After exiting the pyrolysis process, only carbon dioxide and steam should come out of the chimney. The presence of dark smoke and odor indicates incomplete combustion of fuel.

Useful video

The video demonstrates how to make a pyrolysis boiler yourself from pre-prepared materials.

Conclusion

When choosing a heating system, it is worth paying attention to different types of boilers and additional elements. A pyrolysis boiler is perfect to obtain a constant coolant temperature during the heating season, does not require frequent addition of firewood. However, it is worth knowing that it will need electricity to operate, the boiler is demanding of the quality of firewood.

Comments