Need ideal heating - it's easier to make it yourself! How to make a boiler with your own hands: on wood and pellets

A wood boiler is a device for heating a certain area, but unlike the frequently used gas and electric models, it uses wood.

This type of boiler has significant advantages: suitable for country houses not connected to the gas pipeline; does not depend on gas supplies - if for some reason the gas is turned off, the house will not be left without heating.

However, You will have to keep an eye on your firewood supply. In addition to firewood, forest waste and pressed wood pellets can be used as fuel.

Wood-fired heating boiler device

- Ash chamber — this is where the ash that forms when wood burns is collected.

- Damper - it serves to supply air for combustion.

- Firewood — the main fuel for the device.

- Combustion zone — this is where the main heat-generating process takes place.

- Water pipes — cold water is supplied through the bottom one, and hot water is discharged through the top one.

- Drain pipe — smoke and gases formed during combustion are removed through it. It can be either vertical or horizontal.

Reference. Pipe position does not affect the effectiveness. Both the first and the second cope with the task equally well.

- Thermostat with chain drive — serves to regulate the temperature inside the boiler and open or close the damper.

How to make a wood boiler for water heating with your own hands

- Tools and materials:

- Welding.

- Angle grinder, grinding and cutting discs, glasses.

- Drill, metal drill bits.

- Gas keys with numbers 1 and 2.

- Hammer.

- A set of keys and screwdrivers.

- Pliers.

- Square.

Boiler manufacturing, drawings

Basically, it can be divided into three stages:

- Manufacturing of the body.

- Assembly.

- Painting.

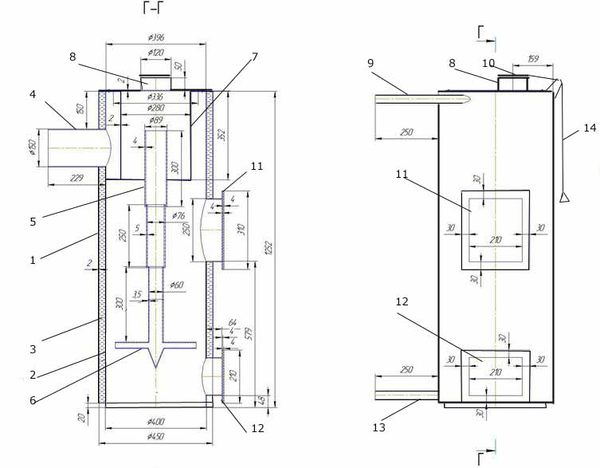

Photo 1. Drawing of a wood-fired heating boiler with dimensions of the device. Front and side views.

Step-by-step production wood boiler:

- Preparation of material. The simplest option is a thick-walled two-hundred-liter barrel. Sheet steel and pipe are also suitable as materials. diameter 80 cm and length 1 m. It is not advisable to use stainless steel, since due to its low thermal conductivity, heating the room will require more firewood.

- Preparing the bottom — the optimal thickness of the bottom is equal to 50 mm.

- Preparing the support — use reinforcement with a diameter of 14 mm.

- Grate - a thick one will do, no less 50 mm thick, metal circle. Slots are made in it, through which the ash from the wood will flow into the ash pan.

- Preparing the metal sheet for a box with a partition.

- Preparing the sheet for water tank (factory one will do).

- Welding of reinforcement inside the body. Fixing it on three levels parallel to each other. The first is the bottom of the boiler, the second is above the ash pit door, the third is 200-220 mm under the top edge of the body.

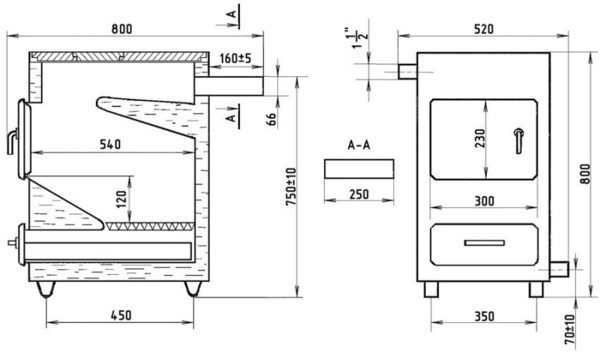

Photo 2. Drawing of a wood-burning metal heating boiler. The device is shown in section from the side and from the front.

- Construction of the box and its division into two sections: for the firebox and for ash. A box is inserted through the opening in the body and fixed by welding.

- Making a blower. You can simply cut a hole in the body, or you can make it in the form of a box - there will be no need to attach a door and it will be more convenient to remove the accumulated ash.

- The bottom is welded not far from the bottom of the body, and a grate is welded above it. The installation level of the latter must coincide with the internal partition of the box.

- A slot is made for the pipe, the door and chimney are welded.

- A water tank is mounted above the boiler at a height of 250–300 mm. It is attached to the wall and placed so that the chimney passes through it. The heat from the pipe will heat the water.

Connection

The sequence below is purely theoretical. The connection should only be performed by a specialist.

- Need a room with access to fresh air.

- In private houses, a space is allocated for the boiler a separate room or extension. It must have a ventilation duct or its own chimney.

- If the project does not specify the exact distance to the walls, then installation must be carried out near the ventilation.

- The room where the boiler will be located must have a window.

- Radiators are connected last.

Difficulties with installation

- Installation of a used boiler — such devices usually suffer from incompleteness, damage or poor condition of individual sections. Maintenance and bringing them into proper condition often exceeds the cost.

- Incorrect installation location — the rolling stock to which the boiler is attached must be strong enough to withstand the load 300-400 kg. Otherwise, there is a risk of damaging the pipelines. The boiler must be at least 32 cm from flammable materials and 26 - from non-flammable ones.

- Harness — pipelines for solid fuel boilers should be installed in such a way that natural circulation of water is ensured due to the temperature difference. The inlet pipeline with cold water should smoothly descend to the very entrance of the main device.

- Pump — the circulation pump must be installed on the return flow of water, this extends its service life, increases efficiency, and also eliminates the formation of air.

- Chimney — installing the damper significantly reduces heat loss, and therefore, excess fuel consumption.

- Ash pan door - when made independently, it must be carefully adjusted to the ash pan to avoid heat loss.

- Inappropriate fuel — it is better to use ordinary, untreated firewood. Sleepers impregnated with creosote, for example, can clog the chimney in two weeks to the point of loss of draft or even overgrowth of combustion products.

Useful video

Watch a video review of a wood-fired heating boiler made by hand.

This is worth paying attention to.

Excess pressure may occur for the following reasons:

- The circulation pump has stopped.

- Incorrect adjustment of automatic control.

- Leak in heat exchanger.

- Faulty or poorly closed make-up tap.

- Lack of coolant.

If any of these cannot be fixed, you will need to call a specialist:

- Faulty safety system. Failure of this system may result in excess pressure. Installation of locks between the boiler and the GB is strictly prohibited.

- Dark smoke, sparks at the chimney outlet, no hum, yellow flame - the chimney is clogged.

Attention! For long-term operation of the boiler follow all operating rules, use dry fuel, as moisture reduces the efficiency level and reduces the service life of the boiler.

Heating a home is becoming more expensive every year, so people are trying to find more economical options, such as a wood-burning boiler.

Comments