Classic among heating devices! Scheme of solid fuel boiler, its dimensions

Solid fuel (SF) boiler – non-volatile component of an autonomous heating systemIt continues to heat the coolant even if there are interruptions in the supply of electricity or gas.

Device "fuel" not only wood, but also other raw materials: peat, wood chips, sawdust, coal, pellets (granules).

Such heating systems are often installed in houses in small towns where there are no central communications.

Content

- The principle of operation of solid fuel boilers

- Popular solid fuel boiler designs and their features

- How to choose a project and build a device with your own hands

- How to properly connect the device to the heating network

- Common problems and their solutions

- Useful video

- Pros and cons of a solid fuel boiler

- Comments (1 opinion)

The principle of operation of solid fuel boilers

The boilers have a modular design a structure consisting of several devices in one housing:

- heat exchanger;

- fireboxes with a door;

- grate;

- ash pan with a hatch for cleaning;

- thermostat.

Heating boiler works on the following principle:

- Fuel is loaded into the chamber and ignited. The wood or alternative materials burn, forming CO.

- The air temperature increases and the gases rise higher into the chimney.

- Hot air currents, displacing cold ones, move through the heating network.

- As they move, the liquid in the heat exchanger heats up.

Responsible for water supply inlet manifold, and for the supply of hot media to the radiators - return manifold. It is recommended to equip both connection points of the circuit with temperature sensors.

Popular solid fuel boiler designs and their features

Projects TT boilers They are mainly distinguished by:

- direction of fuel combustion;

- material;

- additional functions.

Boiler drawings are used more often with top or bottom combustion. Boilers are built from brick and/or metal. If necessary, the system is equipped with a cooktop.

With top combustion

Standard boiler models have a vertical cylindrical design with a heat exchanger designed as a “water jacket”.

Photo 1. Three solid fuel boilers with upper combustion. The devices have a cylindrical shape.

Oxygen is supplied to the boiler from top to bottom through a telescopic pipe. Fuel combustion occurs in the boiler in the same direction.

As the wood burns, the movable distributor gradually sinks under the influence of its own weight. Under pressure, the next part of the wood mass in the bookmark begins to smolder. The fuel is burned in stages and releases a large volume of gas.

Bottom burning

In the boiler design More often, two cameras are used:

- A firebox with vertical or horizontal loading. It is where the wood is burned.

- Afterburning section. Here, the carbon dioxide emitted by the wood burns completely, heating the air and the coolant.

Staged combustion of fuel in traditional solid fuel boiler schemes provides reverse thrust. The flame covers only the lower layer. As it burns out, the upper volume of the load is lowered to the place of the coals, and the latter are poured into the ash pan. In cast iron boilers, a "jacket" is installed around the load chamber, in steel boilers, a "coil" is used.

Reference. To eliminate energy loss in solid fuel boilers, the afterburning section is finished fireclay bricks. It is not necessary to install a forced draft fan during assembly.

With hob

Technically, the devices resemble a conventional wood-burning stove. Boilers perform several functions at once:

- heat the room using convection or a heat carrier;

- heat water using a flow-through method if there is an appropriate circuit and connection to the DHW network;

- perform the function of a plate.

Photo 2. Solid fuel boiler with a hob. The burners of the device are made of cast iron.

Considering the tendency of steel to deform, under the cooking surface in the boiler cast iron is used. Any metal of sufficient strength is suitable for the manufacture of the boiler heat exchanger. The register design is performed according to the serpentine or "water jacket" scheme. The panel under the stove is installed directly above the fuel combustion chamber.

From brick, its dimensions

Devices of this type of boiler are a regular furnace with a heat exchanger inside. There are two options for installing the register. in the boiler:

- In the afterburning system. Due to the lower temperature of water heating, this method is more often used in utility and auxiliary rooms of small area.

- In the combustion zone of the bookmark. In this case, it is necessary to increase the dimensions of the chamber. The basis for the register is heat-resistant steel with a thickness from 3 millimeters and more.

The boilers operate on the principle of pyrolysis. Combustion products are removed by natural draft through the chimney.

Standard design boiler includes:

- bunker - a chamber for loading fuel;

- grates for supplying air to the firebox;

- heat exchanger in the form of a tubular coil or storage tank;

- chimney for removing gases;

- mechanical draft regulator.

In domestic boilers for 25 kW, the following dimensions of parts are used:

- loop controller - 1039 mm;

- loading hatch - 1190 mm;

- ash pan door - 430 mm;

- smoke exhauster - 618 mm;

- coupling - 1289 mm;

- emergency branch pipe - 1101 mm;

- supply line of the circuit — 1126;

- cold water supply - 765;

- going online — 880 mm;

- return - 41 mm;

- expansion tank - 990 mm.

The size of the boiler elements directly depends on the power of the equipment.

Reference. Brick is a poor conductor of heat. It saves energy with minimal losses, heats the air and water in the register well.

How to choose a project and build a device with your own hands

When developing a boiler drawing The following characteristics are taken into account:

- Area of the heated object. The required power range and (sometimes) the type of fuel depend on it.

- Ceiling height. The indicator is taken into account when developing ventilation and chimneys.

- Level of heat loss of the building. Determined taking into account the thickness of the walls and ceilings, the type of material at the base of the structure. Heat loss is also affected by the number and size of openings - windows and doors.

It is easier and safer to order a professional boiler diagram. If this is not possible use the standard formula: 1 kW rated power for every 10 square meters area, with a ceiling height equal to 3 m. A reserve is added to the result. 1-2 kW.

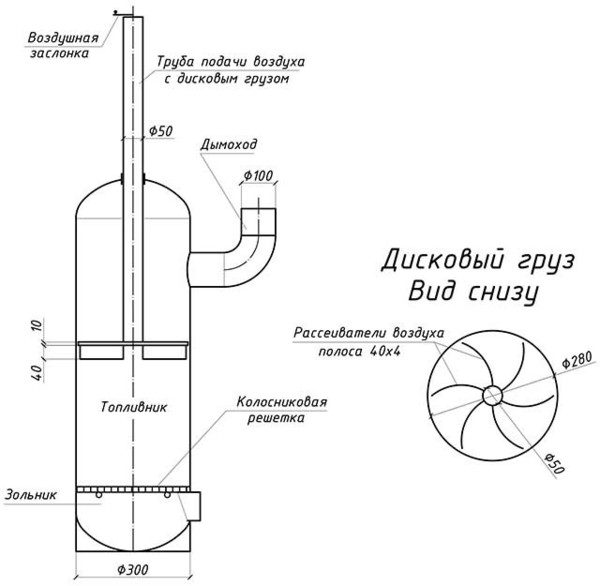

The pyrolysis boiler project must include air supply pipe and a load that exerts pressure on the fuel during combustion. The capacity of the boiler combustion chamber is calculated taking into account the type of equipment and the specific heat of combustion in order to ensure optimal loading frequency.

Materials and tools

It is easier and faster to make a pyrolysis boiler from a used gas cylinder. In addition to this, you will need:

- carbon based metal sheets 5mm steel;

- corner pipe cutting D110—120;

- pipe for air duct D80—90;

- pipe under the chimney riser D120—140;

- adapter for pipes of the corresponding diameter;

- asbestos cord or fiberglass;

- metal corners for boiler legs;

- steel rod cuttings and strip 1x50 mm;

- dry concrete mix for foundation construction.

The tools used include an electric welding machine, a grinder and an angle grinder. Prepare in advance 10-12 grinding wheels for cleaning boiler joints and seams.

Large holes perform gas or plasma cutter. You will also need a standard one. set of locksmith toolsTo ensure that the workpieces are precise and even, the material is first marked with a marker.

Construction from a gas cylinder: step-by-step instructions, drawings

Before use from the container Bleed off the remaining propane and rinsed. To do this:

- Unscrew the fixing bolts on the neck and drain the gasoline.

- The cylinder is filled with water and kept there 2-3 days.

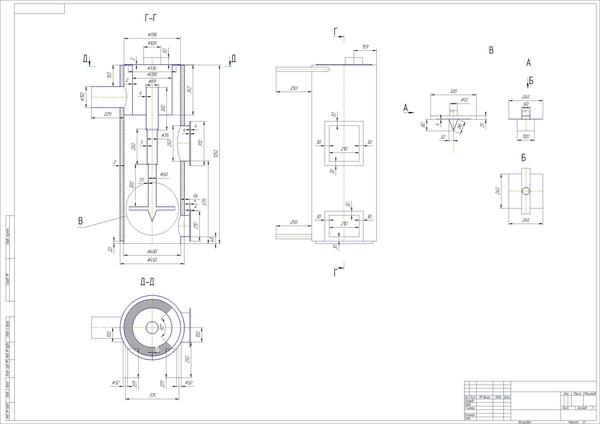

Photo 3. Drawing of a solid fuel boiler from a gas cylinder. The device is shown from different sides.

To prepare the firebox for the boiler, the product sawed with a grinder along the transverse line of the "shoulders" of the container. The length of the resulting cylinder is about 130 cm — this section is where the fuel is ignited.

Important! Sawed off the neck is not thrown away. It will be useful as a lid for the finished boiler.

For heating boilers are manufactured knee extension:

- A hole is cut in the side wall of the cylinder for the corner pipe D110—120 and bring it out perpendicular to the cylinder.

- An adapter is installed on the upper edge and sealed with asbestos cord or fiberglass.

- A chimney riser made from a pipe of a larger diameter is connected to the pipe through an adapter - 120—140 mm.

Photo 4. Drawing of a solid fuel boiler made from a gas cylinder. The dimensions of the device are indicated.

Due to the difference in width, the efficiency of the equipment increases.

A lid is made from the neck for the boiler:

- For ease of use, handles made from a metal rod are welded to the workpiece.

- A short pipe is installed in the center to guide the “piston”.

- A hole is made in the branch pipe using a cutter for the air duct system from a dividing plate with a telescopic pipe.

A metal strip is welded along the edge of the cylindrical body of the boiler at the junction with the lid to limit the shift of the neck. One of the two "pancakes" obtained by cutting out the holes for the cylinder is used as a delimiter. This part separates the burning gas from the fuel.:

- The workpiece is turned to reduce the diameter.p to 1/20 part and leave a gap between its edges and the walls of the cylinder.

- Blades made of metal tape are welded to the plate in quantity 6 unitsThey ensure uniform combustion of wood in the firebox and afterburning of wood gases.

- A hole is made in the middle and a pipe is welded in.

The finished divider with the air duct pipe is installed in the cover through the cutout. The system provides the necessary oxygen supply to the boiler firebox from top to bottom.

Reference. If desired, a second, narrower plate with a hole can be installed in the center of the distributor. D30—40 mmThanks to it, a gap is maintained between the fuel mass and the blades for the unimpeded removal of gases.

Greater efficiency can be achieved by supplementing the boiler "water jacket". If there is a circuit, the solid fuel boiler heats several rooms at the same time. Heat exchanger into the boiler installed in two ways:

- on the body;

- on the chimney.

It is easier to implement the scheme using the first method. To prepare the heat exchanger (outer casing), the steel sheets are cut 6 metal plates:

- square 600x600 mm — x2;

- rectangular 120x60 mm — x4.

Elements of the boiler design assemble according to the following scheme:

- In the center of the plates 600x600 mm make round holes exactly to the outer diameter of the cylinder.

- All the blanks are welded. The bottom and lid of the boiler are made from square ones, and the walls from rectangular ones.

- The resulting “shirt” is placed on the cylinder, and all open end parts are covered with metal scraps.

- In the upper part, make a hole for the inlet, and in the lower part - for the outlet branch pipes. Through them, the device is connected to the heating system.

Efficiency pyrolysis boilers 85%. Such efficiency of boiler use is achieved only due to the optimal quality of firewood - in this case, the firewood should be as dry as possible. The boiler is mounted at a height not less than 50 cm relative to the floor level on a flat concrete base. A gap is left between the "shirt" and the wall. The design uses a tin chimney pipe with an outlet in the ceiling and roof of the boiler room. The optimal length is 2 meters.

How to properly connect the device to the heating network

In the described design, a forced piping scheme is most often used by means of two pipes. The first one is connected to the supply circuit, and the second one to the return circuit.

The order of actions is as follows:

- Both pipes are tied with flax tow. The winding is covered with sealant.

- A corner is installed on top and a barrel with a nipple is screwed on.

- All parts are tightly joined and connected to the tap, and the threaded areas are treated with sealant.

- The water circuit is connected to the pipes for circulation of the coolant using a coupling and a nut.

Before starting the heating system perform a test check, to ensure there are no leaks.

Common problems and their solutions

Malfunctions in the boiler operation occur more frequently due to violations committed during:

- choosing a chimney;

- welding of "shirt" pipes;

- threaded connection;

- calculation of the slope of the heat exchanger.

If smoke appears after loading raw materials into the boiler, then the problem is with the draft. It also prevents normal combustion of fuel in the boiler.

Attention! Before construction it is necessary to obtain advice from an engineer to calculate the height and diameter of the structure.

When resinous discharge is formed in the boiler it is recommended:

- increase operating temperature up to 75 degrees or more;

- clean the inner walls of the chamber;

- maintain the temperature of the water in the return line at the level from 55 degrees and more with a 3-way valve.

Damp or low-calorie firewood often prevents the fire from burning evenly and heating the room.

Useful video

Watch the video, which talks about the features of choosing a solid fuel boiler for heating a private house.

Pros and cons of a solid fuel boiler

Solid fuel heating boilers compare favourably with alternative models:

- firewood is cheaper than gas and electricity;

- wood waste such as shavings or sawdust is also used for kindling;

- the room heats up evenly and cools down longer;

- the boiler can be easily connected to both hot water supply and the heating network;

- The equipment is environmentally friendly and has a high Efficiency up to 85%.

Flaw design in the need to constantly monitor that the boiler does not overheat. Firewood is added manually as the fuel burns out. One download on average it's enough for the boiler for 2-4 hours. In addition, the boiler requires regular cleaning due to the rapid accumulation of soot in the chimney and on the walls of the body.

Comments