Savings are several times higher! Features of a long-burning water boiler on wood with a heating circuit

Long-burning devices differ from conventional ones in that the fuel in them does not burn, but smolders. Most of these devices have two modes of operation - intense and long-lasting combustion.

The structures are ignited in intensive combustion mode and the room is heated in long-term mode.

Features of wood-fired heating boilers

Wood fired boilers, are not very different from each other: combustion chamber dimensions and materials of manufacture.

Heating devices are made of steel or cast iron. Each boiler has its own advantages and disadvantages.

Cast iron heating device works stably, takes a long time to heat up, but also takes a long time to cool down. Such devices work not less than 20 yearsThe disadvantages include the fact that with irregular use and sudden temperature changes, cast iron deteriorates.

Steel boiler will serve no more than 15 years. At the same time, steel is a more heat-resistant material, and therefore will not be destroyed by frequent temperature changes. Steel boilers are subject to corrosion, so they must be installed in a dry room.

Advantages

- eco-friendliness, since carbon monoxide released during fuel combustion is processed and used to produce combustible gases;

- combustion control firewood using air supply;

- high efficiency;

- possibility of use various types of solid fuel;

- heating of premises for any purpose;

- autonomous work.

Flaws

- need to control fuel moisture;

- selection large amounts of soot and ash;

- availability of additional space for fuel storage;

- uneven heating coolant;

- the presence of a chimney.

Design of the device

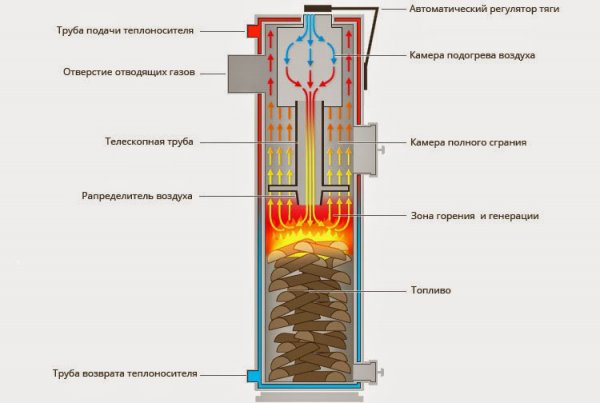

The design of a long-burning boiler is not too complicated. The heating device consists of:

- Closed cylindrical tank, where there is a hatch for loading firewood, a blower and an opening for the chimney.

- Air distributor, located inside the tank. The distributor creates swirls of air flows and combustible gases.

- Heat exchanger, built into the upper chamber. It achieves the maximum temperature.

To regulate the air supply and, therefore, the intensity of combustion, the boiler is equipped with a regulator, which is closed as soon as the wood begins to burn intensively. The boiler is switched to the long-burning mode.

The firewood smolders in the lower chamberIn this case, combustible gases rise to the top and burn in the upper chamber, heating the heat exchanger.

Photo 1. Scheme of the device of a long-burning heating boiler on wood. The arrows indicate the parts of the structure.

Operating principle

The operating principle of a long-burning wood boiler is based on to regulate the air supply to the combustion chamber. Due to the limited amount of oxygen, the combustion and smoldering of the fuel slows down, which allows you to add firewood less often.

Because smoldering occurs in a large volume, carbon monoxide is formed, which has a high calorific value. The gas enters the combustion chamber through a fireproof nozzle and ignites.

Such boilers not only save fuel, but also burn a large amount of harmful compounds and only non-combustible smoke enters the chimney, which does not pollute the environment.

The fuel in the heating device starts to burn from the top layer, then the smoldering gradually descends to the lower layers of firewood. This method slows down fuel combustion, while increasing heat supply.

Do-it-yourself long-burning wood boiler with a water circuit

To create a long-burning boiler you will need:

- Steel pipes or barrel diameter not less than 0.3 m and wall thickness 3-5 mm. Thin-walled containers will quickly burn out and the heating device will become unusable.

- Pipes with diameters of 5 and 10 cm.

- Sheet steel thickness 4 mm.

- Welding machine.

- Bulgarian.

- Hand tools.

The boiler body is formed from a pipe or barrel. The height of the device is determined depending on the size of the combustion chamber and the desired amount of firewood in one load. Optimal height counts 1 m.

Important! You should not make the boiler too high. When a large amount of fuel smolders, a lot of pyrolysis gases are released, which may cause the device to malfunction.

Conventionally, the entire installation can be divided into three zones:

- combustion;

- combustion;

- downloads.

The last zone decreases as the fuel smolders. One of the main elements of the boiler is the distributor. It is made of a steel sheet, in the middle of which there is a pipe for supplying air to the combustion chamber. As the wood smolders, the distributor gradually descends.

To supply air, it is used pipe with a diameter of 5-6 cm. At the same time hole in the air distributor should not exceed 2 cm, so that oxygen oversaturation does not occur. To regulate the draft, a movable valve is installed in the upper part of the pipe.

Photo 2. Homemade long-burning heating boiler made from a metal barrel.

A water heat exchanger pipe is installed inside the combustion chamber. diameter 10 cmIn the tank itself, the water is heated by a coil, which is connected to a pipe.

Connection to the heating system

Long burning boiler connects to the heating system in two ways:

- The water is heated inside the combustion chamber by a coil to which a heat exchanger pipe is connected.

- The water is heated in a remote tank through which the chimney pipe passes.

The second way more difficult in the design, but much more effective.

Chimney and reflector

The walls of a long-burning boiler will constantly heat up and radiate heat. If the room for installing the boiler is small, then around it reflectors are located, distributing the flow of thermal energy and directing it inward.

The chimney pipe is made with a minimum number of elbows - 2 elbows at 45°.

Reference. The chimney is being made collapsibleto make it easier to clean.

Installation

The boiler will constantly heat up, which can lead to a fire. To prevent this from happening, the device installed on a brick or concrete foundation.

If it is not possible to build a foundation, legs are welded to the bottom of the boiler.

In this case, the heating device can be installed on a thick steel sheet. The sheet must protrude beyond the boiler at least 20 cm on each side.

Useful video

Watch the video, which tells about the features of long-burning wood boilers, their operating principles.

Let's sum it up

Making a long-burning boiler with your own hands will allow you to save not only on the purchase of expensive equipment, but also during operation. You can use such a heating device in living quarters, garage, workshop, etc. The heating device will provide highly efficient heating at minimal cost.

Attention! After making a long-burning wood boiler with your own hands, it is necessary to connect correctlyOtherwise, all your efforts to reduce costs will be in vain.

A properly functioning heating device will save you money and time during operation. You will need to load firewood 2-3 times a day depending on the size of the combustion chamber. The smoke coming out of the chimney should not contain harmful compounds. If the device is improperly designed or connected, you may become the owner of a very capricious device. Signs of malfunction long burning wood boiler include:

- The heating device begins to “eat” firewood in large quantities, and One download lasts for 2-3 hours. There is no talk of any cost savings in this case.

- There is no possibility of adjustment heating temperatures.

- Unable to reheat device to temperature above 60 °C.

- During the heating Explosions are heard in the chimney.

- From the chimney tar is flowing.

- Boiling boiler.

- At high temperature of the device itself the batteries remain cold.

Only one can help in this case reconnecting the boiler to the heating system and chimney. You should carefully study the device piping diagrams or contact specialists.

Comments