You don't need to look after it 24/7! Long-burning wood boiler, its features

Tourists have the duty of a "fireman" - he monitors the safety and intensity of the flame in the fire. Owners of private houses with wood heating automatically become "bonfire".

It is inconvenient to make sure the fire does not go out and to keep another batch of firewood at hand.

The solution to the problem is a long-burning boiler. Unlike the traditional grate has an increased firewood load, higher efficiency, and automatic control.

Types of long burning wood boilers

Long burning boilers are:

- Controlled grate. These are standard serial boilers, in which an adjustable turbine, automatic control, connected to a pump and sensors are installed. It burns on 25-30% longer than usual.

- Pyrolysis with shaft loading. These boilers use the principle of wood decomposition into combustible gases, which are burned in a separate chamber. They burn for a long time, have excellent controllability and efficiency.

- With portioned combustion of fuel. The principle of top combustion and the technology of air supply through a telescopic air duct allow for hot optimal combustion. A large load of firewood does not burn completely, but burns down from top to bottom.

Characteristics of wood boilers

The cost of a home heating system does not allow for mistakes - when replacing a boiler the harness will also have to be changed, which is expensive and complicated. It is important to consider the pros and cons of long burning technology to make the right choice.

Pros

- Large reserve of burning time. The intervals between fireboxes reach several days, during which time there is no need to enter the boiler room. Suitable for owners who are away from home for a long time, as well as those who value their personal time.

- Thanks to the gradual combustion of fuel and the heat removal system Efficiency boilers increases to 90%. TThe temperature of the outgoing gases in the pipe is lower than in traditional furnaces, all the heat is transferred to the coolant.

- Firewood as fuel is available wherever people live. Most wood-fired boilers allow you to save additionally on fuel - they also use sawdust, pallets, sunflower husks, crushed straw and other waste.

- Long burning technology has been mastered by all major manufacturers of heating equipmentA good sample can be purchased anywhere.

- The enclosed installation instructions describe all the conditions for correct operation. They rarely differ from conventional boilers, and no modification of the heating system is required. As a rule, the safety group, automation, and sensors are mounted on the boiler body.

- Thanks to the well-thought-out design long burning boilers last a long time. The technology has been studied, and the "childhood" diseases have long been cured. Manufacturers supply spare parts to the market and provide warranty and post-warranty service. Depending on the manufacturer, the warranty is from 5 to 15 years.

Cons

- Increased fuel loading. It is impossible to throw in a couple of logs for easy kindling in such structures; a large bunker is loaded at once.

- At the request of manufacturers and according to fire safety regulations for installation A special room is required - a boiler room. If there is no such room, you will have to build a separate building and install a heating main into the house.

- Long burning boiler during operation forms a large amount of soot and condensation. Therefore, cleaning of the chimney and heat exchangers is performed more often.

Attention! If you neglect the chimney cleaning procedure, the deposits in them may ignite. The temperature of burning soot is high, the pipe becomes hot, deforms or breaks. Violation of safety precautions leads to fire!

How does the device work?

For burning wood and wood waste It is better to use the principle of top combustionThe design of such a boiler is simple and allows achieving phenomenal results in terms of duration and efficiency.

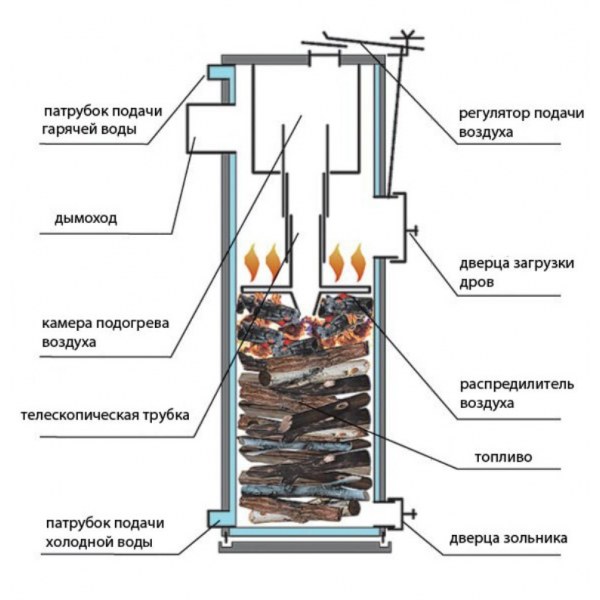

Photo 1. Scheme of a long-burning wood boiler. The wood burns from top to bottom.

The operating principle consists of supplying air not from below, through the grate, but from above - through a special air duct. The fuel does not burn throughout the entire mass of the load, but in portions from top to bottom. The firewood below the combustion zone is at room temperature! Combustion in the air supply zone occurs at maximum speed, which allows for complete combustion of the firewood.

Solid fuel boiler with top combustion consists of the following parts:

- Frame. Most of them are cylindrical. The body consists of a loading cylinder, a water jacket and an upper insulated part. The body has sealed doors for loading fuel at the top and an ash door at the bottom.

- Movable combustion chamber. Its shape resembles a "pancake" or "spider". The essence is to distribute air over the surface of the wood and maintain combustion. The pancake, as a rule, is massive and heats up during operation and acts as a kind of "flywheel" - it makes combustion more even.

- Telescopic air duct. Air flows through it to the "pancake". It consists of several elbows that are gathered with a cable. The "pancake" is fixed at the bottom, and the air quantity regulator is at the top.

- Secondary combustion chamber. Not all boilers of this type have it. It is located in the upper part of the boiler or in the upper part of the primary chamber. The secondary chamber is needed for afterburning of unburned pyrolysis gases.

- Heat exchanger. The body and additional ribs in the upper part of the boiler act as this. The efficiency of heat removal directly depends on the cleanliness of the surfaces.

- Automatic control. Mounted on the body, can be mechanical or electronic. Mechanical will maintain the set temperature of the coolant throughout the entire combustion time, electronic is able to change the temperature depending on the time of day and the set program.

The unusual design of the top combustion furnace causes a lot of controversy. But operating experience shows that it performs its functions perfectly. This boiler differs from traditional and in appearance, and in structure, and in the principle of operation.

How to stoke correctly

Solid fuel boiler type "Stropuva" works according to the following scheme:

- Fuel loading. To do this, you need to lift the "pancake" to the top position so that it is above the loading door. Pack it tightly (large logs are sprinkled with sawdust). Kindling is placed on top - dry chips and paper.

- Ignition. With the top door open and the air duct closed, we light a fire from kindling. The boiler works as usual until the temperature in the water jacket rises up to 50-60 °C.

- Combustion. Upon reaching the set temperature, the door closes tightly and the telescopic air duct regulator opens. After some time, the boiler enters the optimal combustion mode, the temperature is set automatically.

- If necessary, adjust the coolant temperature is produced by the air duct damper.

- After the fire is finished, the ash is cleaned. a new batch of firewood is being loaded.

There is a three-way valve in the boiler piping - water jacket temperature should be at least 60 °CThis is necessary so that the wood burns in an optimal mode.

Connection to the boiler can be made polypropylene pipes — a safety group is installed on the boiler and the overheated coolant will not reach the plastic.

Photo 2. Loading firewood into a long-burning boiler. They should be slightly shorter than the length of the firebox.

Useful video

Watch the video, which talks about solid fuel boilers with long burning, their characteristics, advantages and disadvantages.

What fuel is used?

The temperature of the gases in the chimney during long-term combustion is significantly lower than in simple boilers. Therefore, when using damp firewood, moisture settles in the chimney and "floods" condensate - a black viscous liquid with the smell of creosote.

Therefore, it is impossible to use the boiler in minimum modes, and fuel must be dry only with a relative humidity of no more than 15%.

These parameters can be achieved by technological drying in a chamber or natural drying under a roof. for 3 years.

For burning pallets, sawdust and other dense and small particles, a specially shaped "pancake" on the combustion chamber.

Laying firewood as dense as possible, without voids. If they lie unevenly, the “pancake” hangs on the protruding parts and the flame goes out.

You can use large firewood, it is not necessary to split it. Split firewood is stacked more evenly. The logs should not be too long - it is better to stack short firewood "standing" in several layers.

Comments